High-unloading slot composite-incision demolition blasting method for reinforced concrete cooling tower

A technology for reinforced concrete and cooling towers, applied in blasting and other directions, can solve the problems of difficult blasting and demolition of tall reinforced concrete cooling towers, reduce the kinetic energy of slump and ground contact, control the vibration effect of ground contact, increase the degree of disintegration and disintegration effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: The reinforced concrete cooling tower in this example is a 6000m2 hyperbolic cooling tower with an overall cast-in-place reinforced concrete structure, the tower height is 120m; the maximum radius of the bottom is 44.586m; the radius of the throat is 26.59lm; the radius of the top is 28.471m, and the tower wall is double Curved surface, the maximum wall thickness of the tower wall is 0.8m; the minimum wall thickness is 0.18m, the herringbone pillar is a cylinder with a diameter of 0.7m, and the height is 5.0m. m.

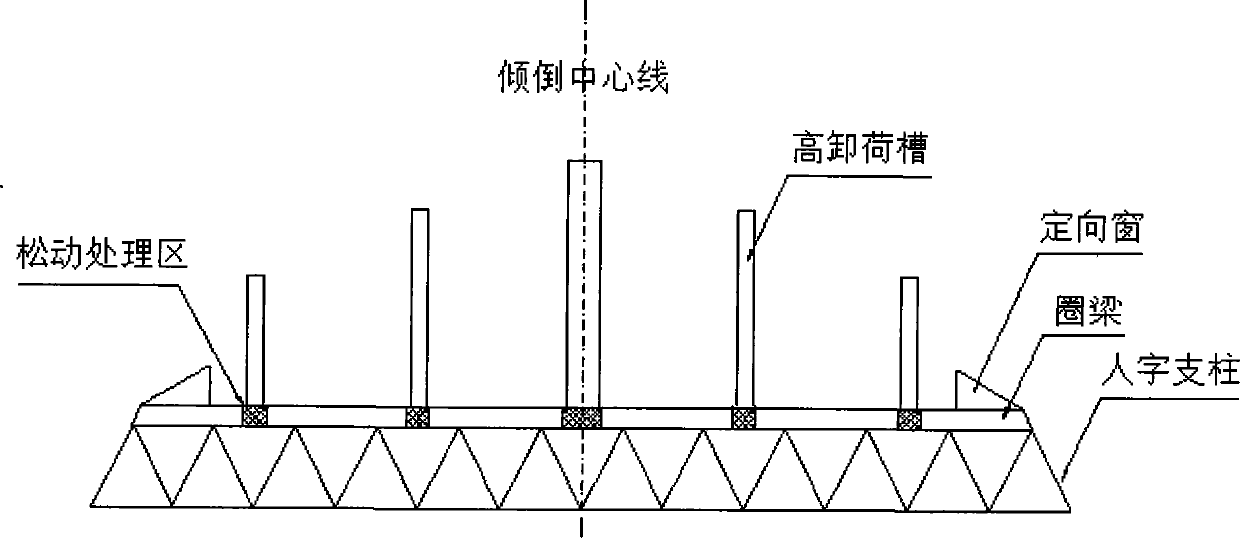

[0030] The blasting scheme is chosen to adopt the composite notch blasting method of high unloading groove, and the blasting notch is set at the bottom of the cylinder, and the overall directional collapse.

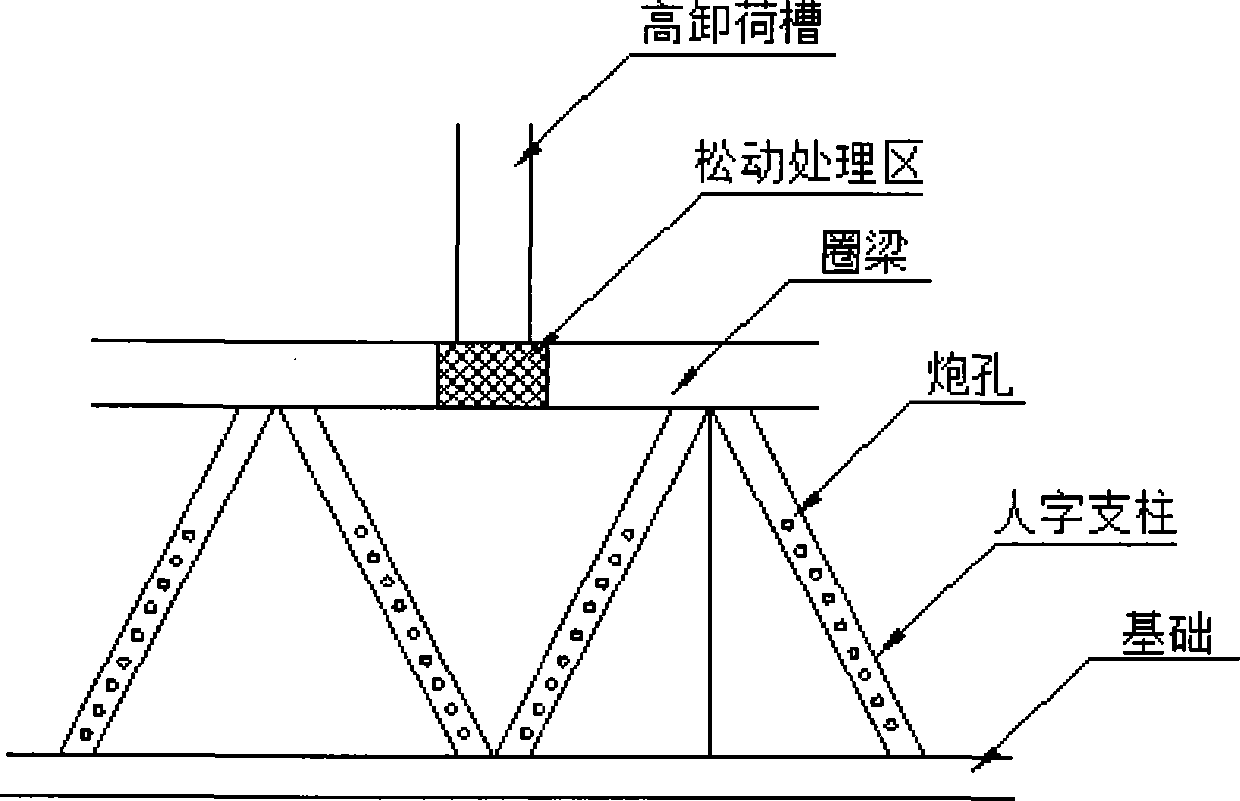

[0031] This example specifically includes the following steps: mechanically remove the water spraying platform inside the cooling tower, cut off the connection between the external pedestrian ladder and the ground, arrange blasting cuts at the...

Embodiment 2

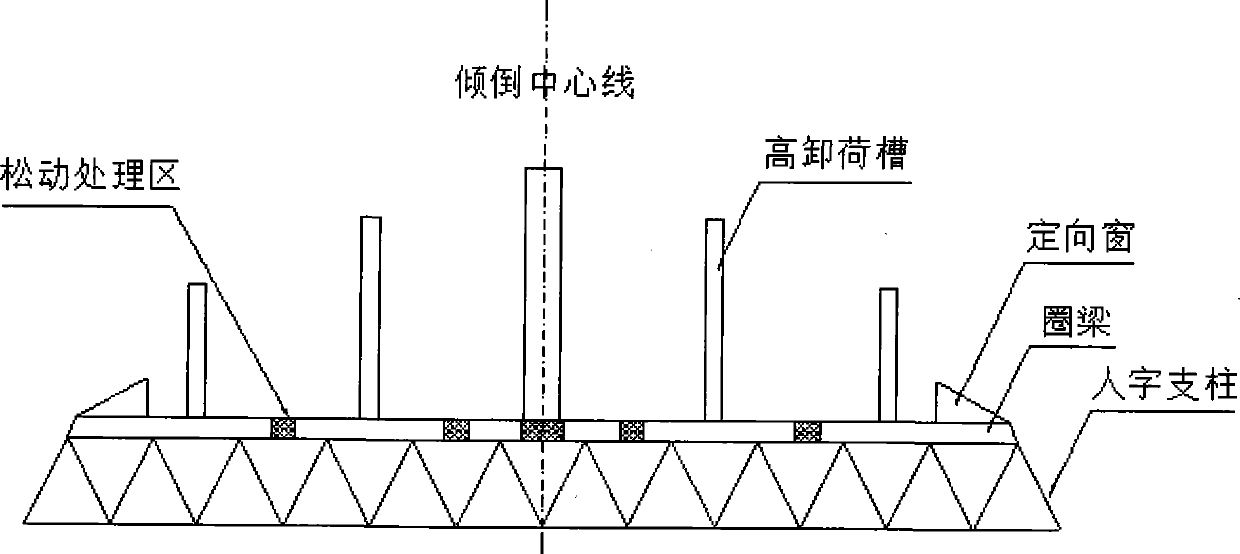

[0051] Embodiment 2: as image 3 As shown, its implementation object is an overall cast-in-situ hyperbolic reinforced concrete cooling tower with a height of 90m. The maximum diameter of the bottom of the cooling tower is 73.546m; the diameter of the throat is 38.8m; the diameter of the top is 43.122m. 140mm, the herringbone pillars are hexagonal prisms with a side length of 450mm, a total of 40 pairs, the elevation is 5.8m, the beam height of the upper ring of the herringbone pillars is 2m, and the thickness is 500mm.

[0052] This embodiment specifically includes the following steps: mechanically remove the water spraying platform inside the cooling tower, cut off the connection between the external pedestrian ladder and the ground, arrange blasting cuts at the bottom of the cooling tower; drill holes on the herringbone pillars; open directional windows on the simplified body; A high unloading groove is set up on the body, and part of the ring beam is loosened. In this examp...

Embodiment 3

[0072] Embodiment 3: as Figure 4 As shown, the height of the cooling tower to be implemented is 100m, the radius of the bottom is 43.80m; the wall thickness of the ring beam is 600mm, the height of the ring beam is 1.25m, and the minimum wall thickness of the top is 140mm; 5m, spacing 6.4m, a total of 44 pairs.

[0073] This example specifically includes the following steps: mechanically remove the water spraying platform inside the cooling tower, cut off the connection between the external pedestrian ladder and the ground, and arrange blasting cuts at the bottom of the cooling tower; Open the directional window; set up a high unloading groove on the cylinder, and loosen part of the ring beam. In this example, the loosening treatment position of the ring beam and the opening position of the high unloading groove are separated, and safety protection measures are implemented; the herringbone pillar test Detonation; charging, connection, non-electric two-way enhanced detonation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com