Blasting construction method for blasting equipment

A technology of blasting equipment and construction methods, which is applied in blasting, blasting cylinders, weapon accessories, etc., can solve the problems of difficult control of blasting hazards, unsatisfactory blasting effect, and high block rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0029] Unless expressly stated otherwise, throughout the specification and claims, the term "comprises" or variations such as or "comprises" or "comprises" and the like will be understood to include the stated elements or constituents, rather than Other elements or other components are not excluded.

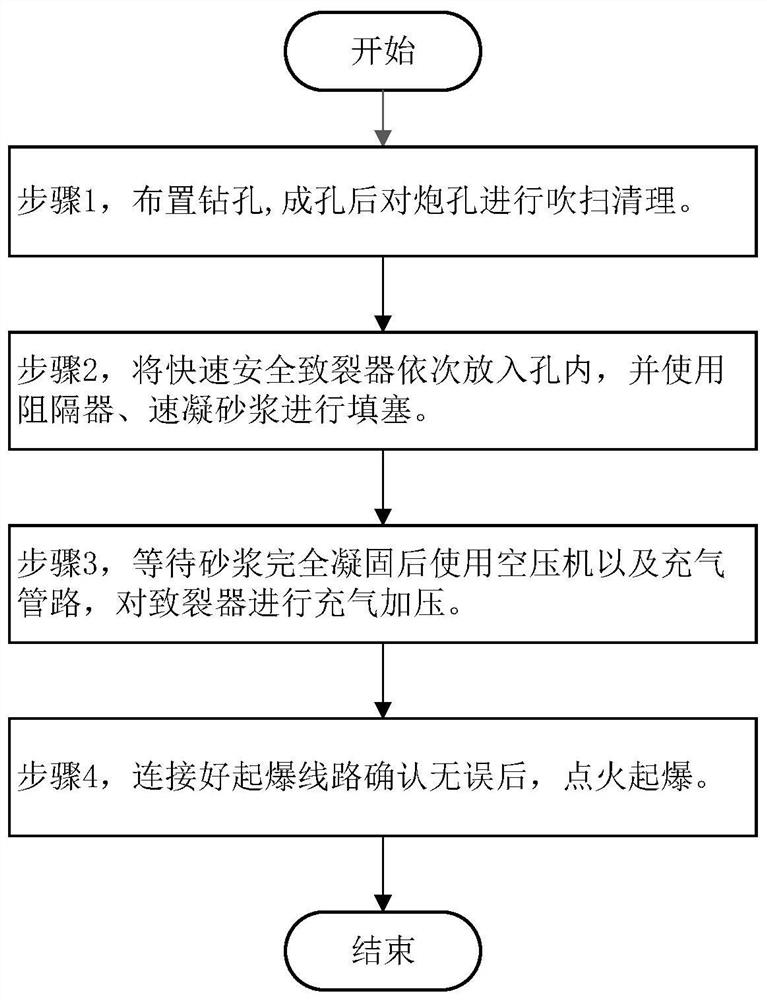

[0030] The invention provides a blasting construction method of blasting equipment, referring to figure 1 As shown, it includes the following steps:

[0031] Step 1, layout of the hole network, the first row of holes is arranged in the direction of the air surface, the hole diameter is greater than 90mm, the hole spacing is 500-1000mm, the second row of holes and the first row of holes are 500-1000mm apart, and so on, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com