Blasting structure of efficient blasting device

A high-efficiency, blasting cylinder technology, applied in the field of blasting, achieves the effects of increasing the utilization rate, reducing blasting vibration, and reducing the unit consumption of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

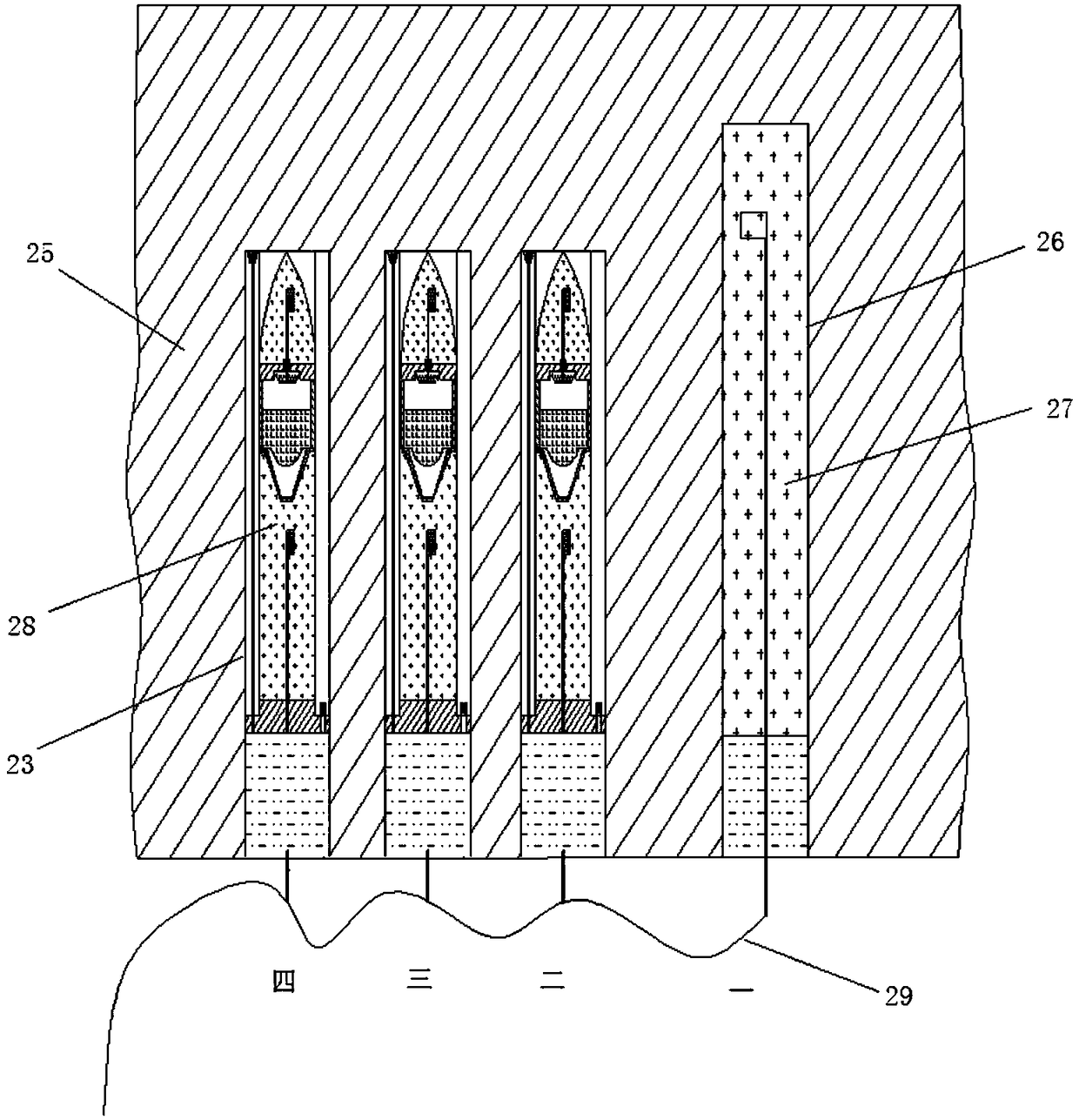

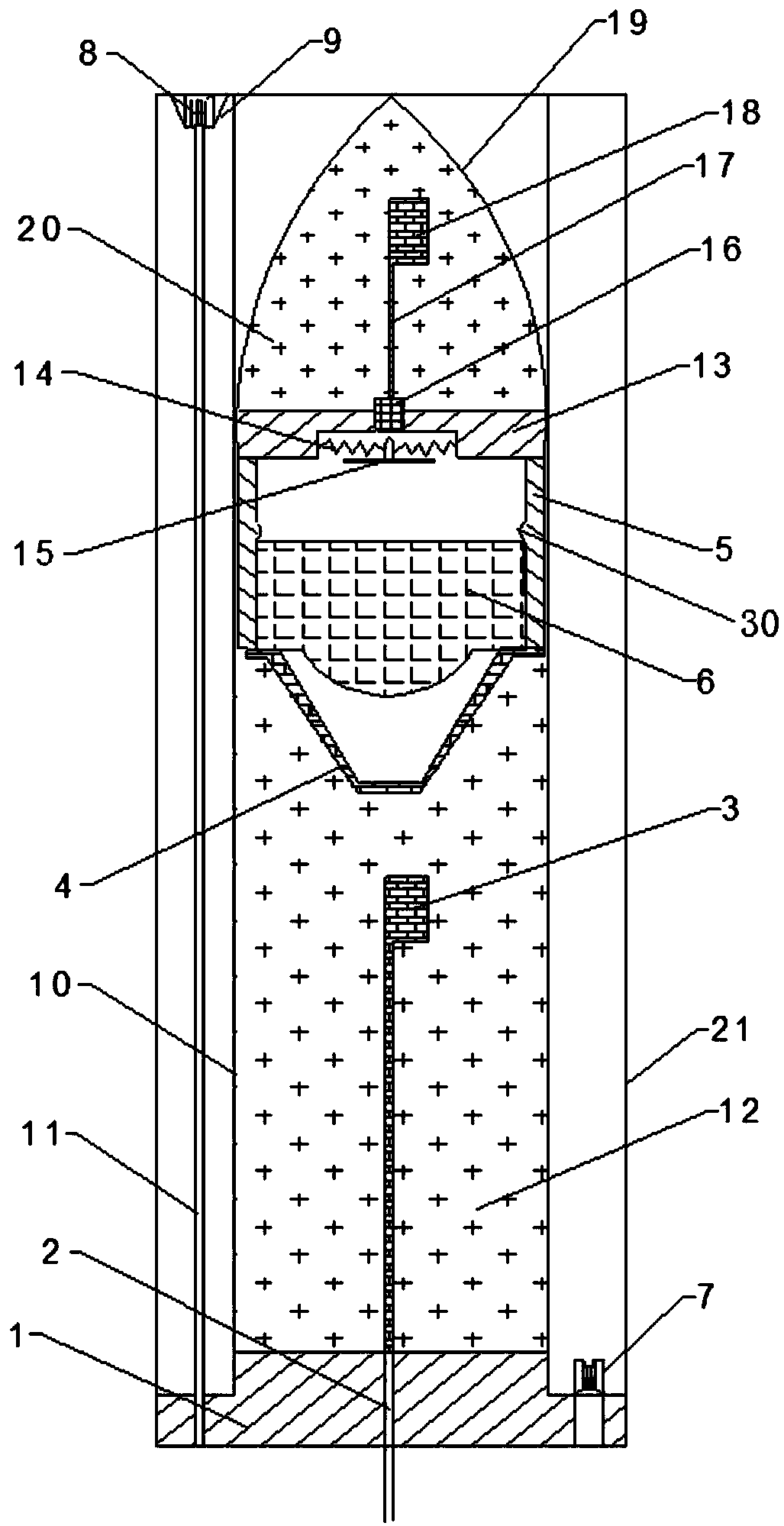

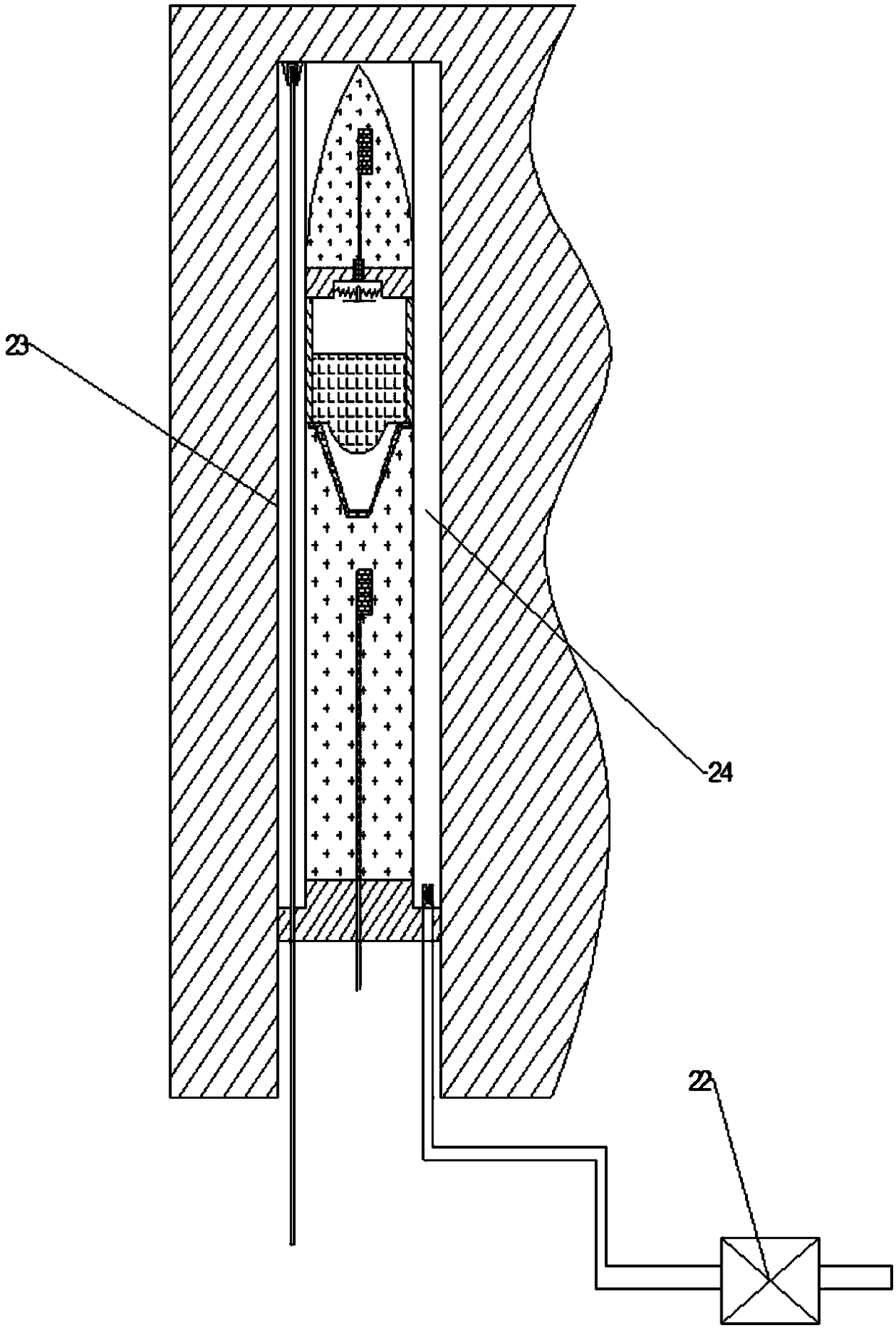

[0015] Embodiments of the present invention: a blasting method of a high-efficiency blasting device, the method forms blasting main blastholes and auxiliary blastholes respectively by drilling holes, the auxiliary blastholes are arranged around the blasting main blastholes, and put Sufficient explosives, blasting devices are placed in the auxiliary blast holes, and the differential blasting technology is used to make the main blast hole first explode on the surrounding rock mass, which can produce a blasting effect on the deep rock mass, that is, rock mass loosening, cracks and stress fields Then the auxiliary blastholes around the main blasthole are detonated sequentially, and the secondary blasting main body of the blasting device in the auxiliary blasthole can be advanced axially into the deep rock body to complete the blasting work.

[0016] The depth of the main blasthole is greater than the depth of the auxiliary blasthole. Generally, the depth of the main blasthole can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com