Electronic detonator initiation system for tunnel blasting

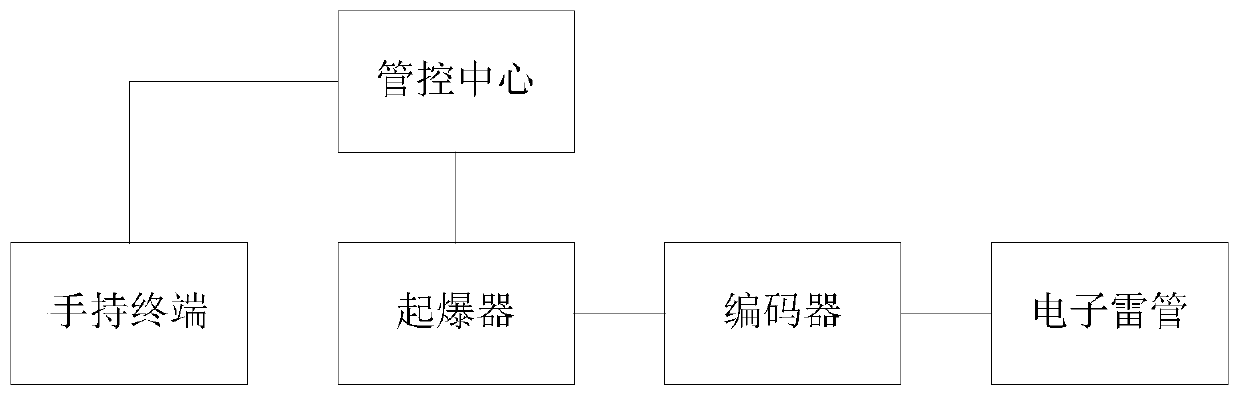

An electronic detonator and tunnel technology, which is applied in the field of electronic detonator detonation systems, can solve problems such as the adverse effects of engineering blasting safety and operation progress, the reduced reliability of electronic detonator detonation, and the deviation of blasting time, so as to reduce the probability of blind shots and avoid The effect of blind cannons, which is not easy to make mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

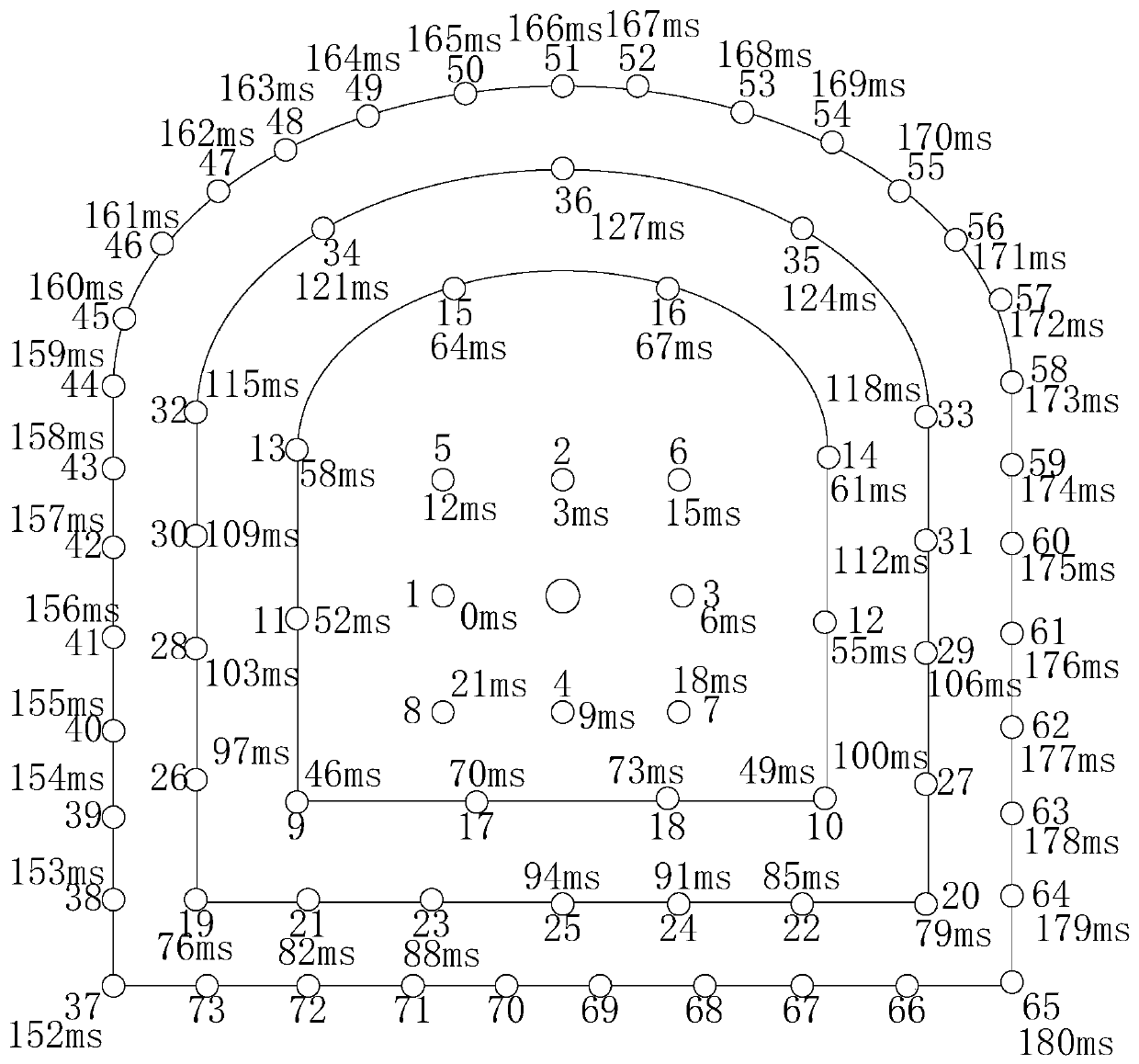

[0033] Full-section excavation, vertical hole trough, blast hole diameter 42mm, circular footage 2.5m, trough hole depth 3m, peripheral hole depth 2.8m, auxiliary hole depth 2.7m, an 89mm hole is drilled in the middle, and the holes are arranged in sequence 8 slot holes, 37 peripheral holes and 28 auxiliary holes. After the single-shot detection of the electronic detonator, the detonator is made, and each blast hole is loaded with a detonator, charged and stuffed. When the electronic detonator is detonated, the reverse detonation method is adopted at the bottom of the hole. The electronic detonator is first placed at the bottom of the hole and then the explosive is filled, and then filled with gun mud or rock slag. Detonate the full length of the detonating cord, then start marking the slot hole of the Taotao set, scan the barcode and set the delay time. For the delay time setting, see figure 2, the delay initiation interval between the cutout holes can be set to 3ms~5ms, th...

Embodiment 2

[0035] Full-section excavation, vertical hole trough, blast hole diameter 42mm, circular footage 2.5m, trough hole depth 3m, peripheral hole depth 2.8m, auxiliary hole depth 2.7m, an 89mm hole is drilled in the middle, and the holes are evenly arranged around 8 slot holes, 37 peripheral holes and 28 auxiliary holes. After the single-shot detection of the electronic detonator, the detonator is made, and each blast hole is loaded with a detonator, charged and stuffed. Positive detonation method is used to charge and detonate, the slot hole and auxiliary hole are continuously charged, the peripheral holes are not coupled to charge, the detonating cord is detonated at the full length, and then the slot hole is marked, the barcode is scanned and the delay time is set. , the delay time is set according to the conventional method, the internal 4 slots are set to 0ms, the other 4 slot holes are set to 25ms, the row of auxiliary holes adjacent to the slot holes is set to 50ms, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com