Method for reducing irradiation damage based on dislocation

A radiation damage and dislocation technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uncontrollable dislocation positions, difficulty in introducing dislocations, expensive equipment, etc., to achieve no contamination problems, The effect of huge industrial advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking silicon material as a specific example, a method for reducing radiation damage based on dislocations includes the following steps:

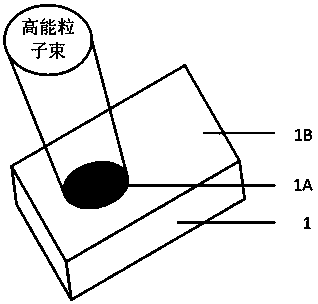

[0026] Such as figure 2 As shown, a single beam of high-energy particles is implanted on the surface of the silicon material 1 , and the high-energy particles in the implanted region 1A are sufficient to destroy the silicon lattice and generate dislocations on the surface of the silicon material 1 . The beam spot diameter of the high-energy particles is 0.1mm to 100mm, and the size of the injection region 1A is controlled by the beam spot of the high-energy particles. As the shape of the beam spot changes, the shape of the injection region 1A changes accordingly. Region 1B that is not implanted with energetic particles will not introduce dislocations.

[0027] High-energy particles include one of protons, neutrons or gamma rays, etc., and the injected dose ranges from 5×10 15 cm -2 up to 5×10 17 cm -2 . The energy range of hi...

Embodiment 2

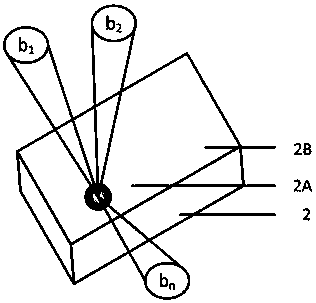

[0029] Such as image 3 As shown, the present invention can also be applied to occasions where it is only necessary to introduce dislocations in the bulk of the silicon material 2 . Multiple beams of high-energy particle beams can be used b 1 , b 2 ... b n Simultaneously implant different surfaces of the silicon material, and adjust the angles between the multiple beams of high-energy particle beams and the respective injection surfaces, so that the multiple beams of high-energy particle beams are focused on a specific area 2A in the silicon material. Under the action of stress, dislocations are introduced in this specific region 2A, while there are few or no dislocations in the region 2B not affected by the convergence of the high-energy particle beam. This method of using multiple high-energy particle beams to introduce dislocations can reduce the power of each high-energy particle beam, effectively reducing its damage to the surface lattice of the silicon material, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com