Pilot-tunneling method for coal uncovering

A technology for guiding tunnels and coal seams, which is used in gas discharge, safety devices, ground mining, etc., can solve the problems of roadway surrounding rock structure damage, difficult control of safety rock pillars, and difficult operation, so as to reduce ventilation pressure and reduce induced coal mining. The effect of reducing the number of detonators and the probability of gas outburst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In conjunction with accompanying drawing, the present invention is described in further detail by example:

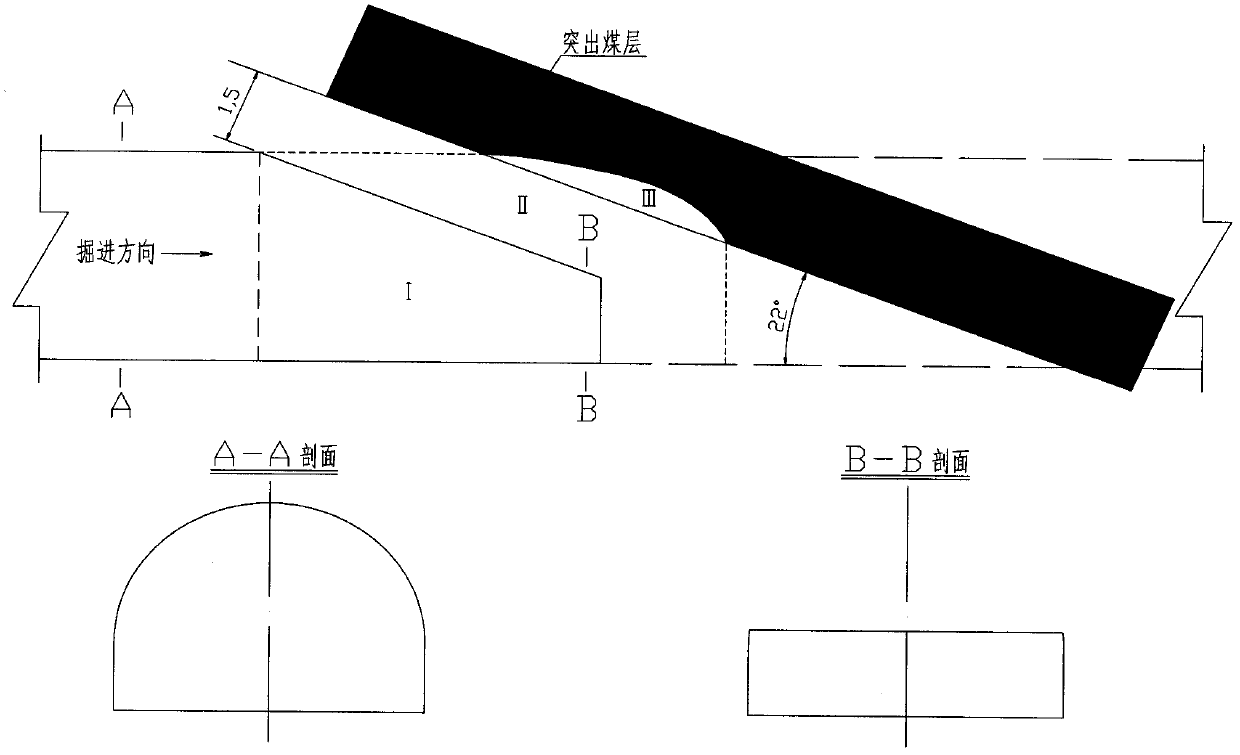

[0011] see figure 1 , The original coal uncovering technology is composed of the following parts: stop the operation of the rock pillar (1.5m); repair the inclined working face I; cloth eye uncover coal formation II; temporarily support the uncovered coal seam part III; permanent support.

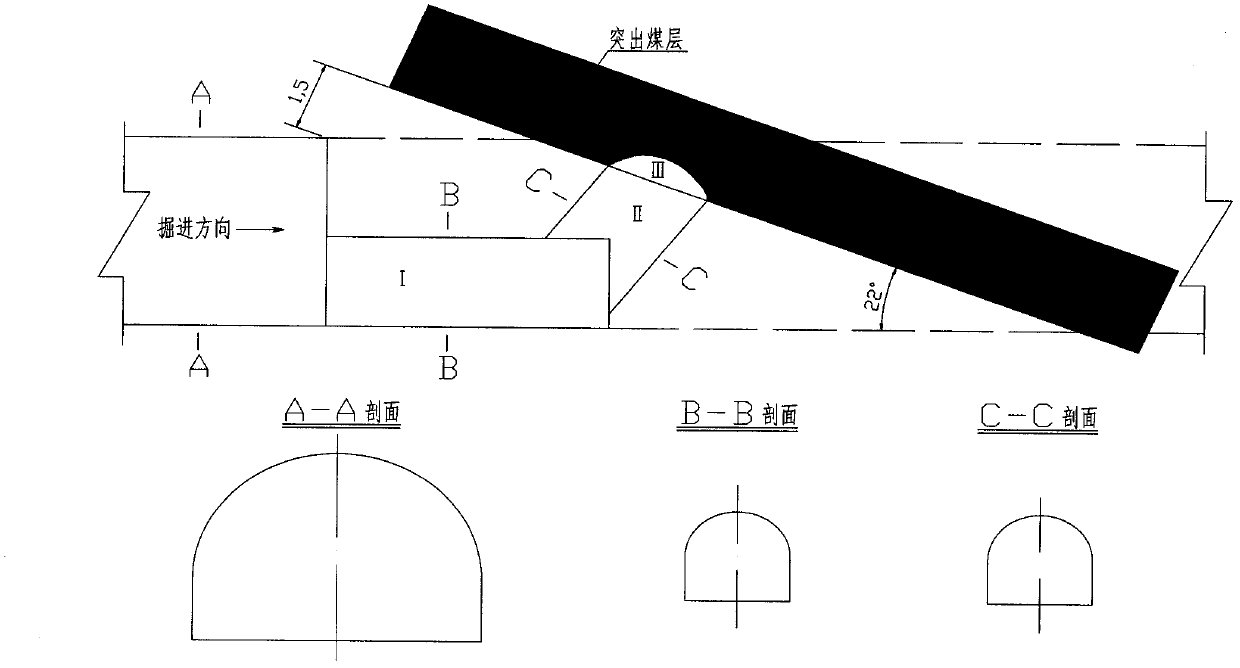

[0012] see figure 2 , the roadway coal uncovering technology involved in the present invention is composed of the following parts: specify the rock pillar construction pilot tunnel I; uncover the coal seam to form the pilot tunnel II; temporarily support the exposed coal seam III; brush and expand the tunnel to the designed section; permanent support .

[0013] Construction sequence of the present invention is as follows:

[0014] 1) At the 1.5m rock pillar, construct the pilot tunnel (that is, the small section) to the specified rock pillar;

[0015] 2) Changing the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com