Simple numerically-controlled machine tool for machining blind holes

A technology of CNC machine tools and blind holes, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of long time consumption and delayed processing time, and achieve the goal of reducing labor intensity, protecting safety, and ensuring processing depth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

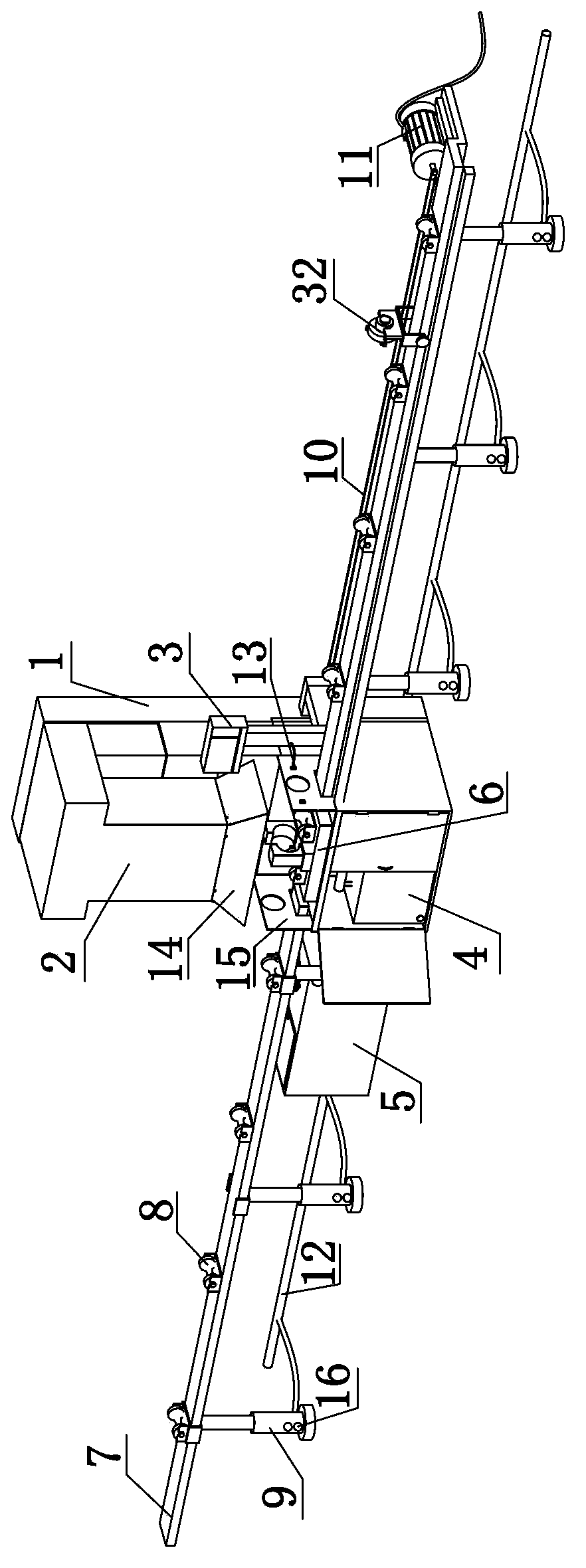

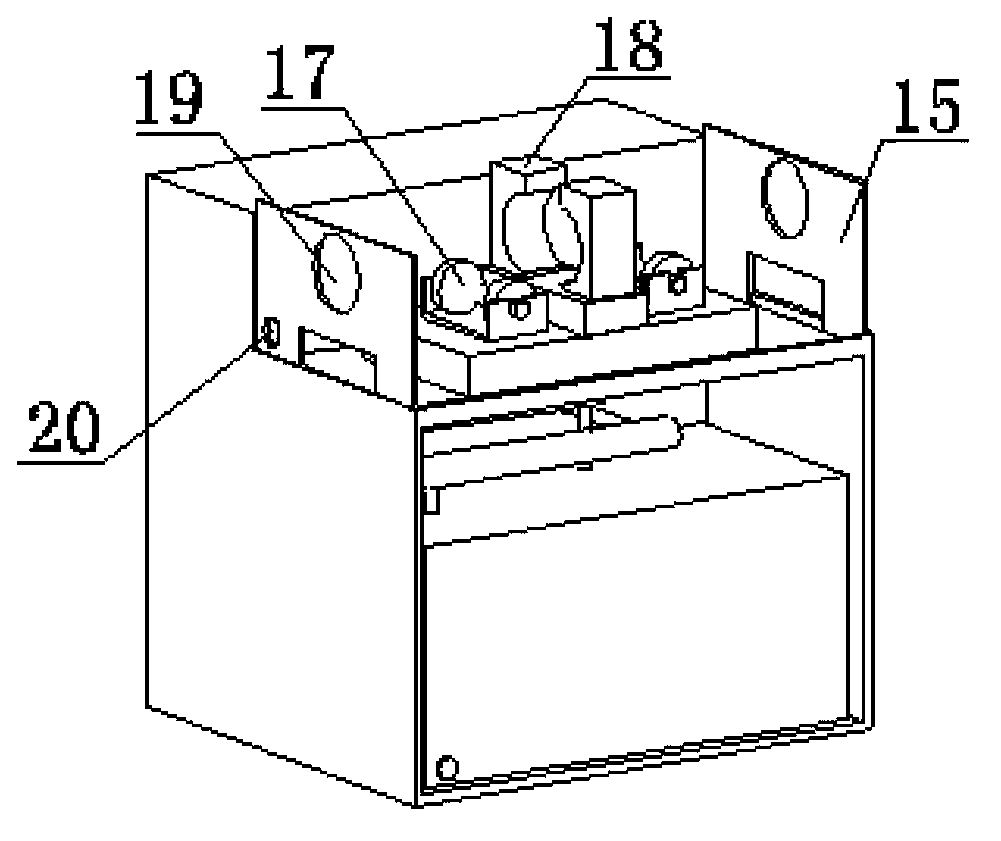

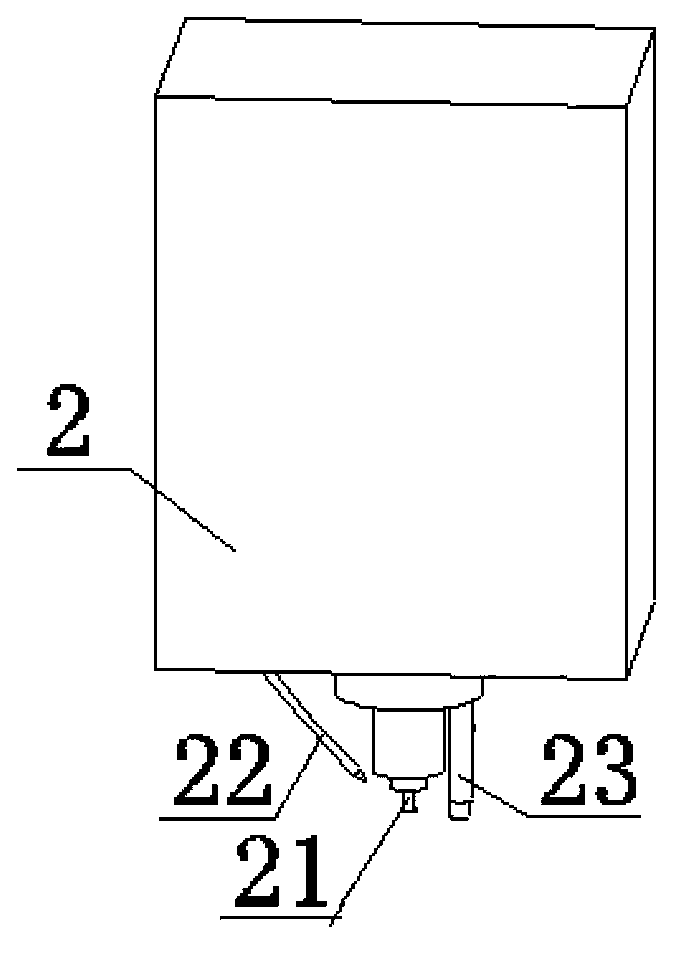

[0027] Embodiment 1 of the present invention: as figure 1 As shown, a CNC machine tool for simple blind hole processing includes a machine tool electrical cabinet 1, a machine tool spindle box 2, a CNC control panel 3, a cutting fluid box 4, a hydraulic oil tank 5, and a workbench 6. The machine tool spindle box 2 is located on the machine tool In front of the electrical cabinet 1, the workbench 6 is set under the machine tool spindle box 2, the cutting fluid tank 4 is set under the workbench 6, and the hydraulic oil tank 5 is set on one side of the machine tool electrical cabinet 1 and passes through the machine tool electrical cabinet 1 The hydraulic oil pipes are connected. There are support platforms 7 on both sides of the workbench 6. The upper end of the support platform 7 is equipped with a transmission roller 8. The lower end of the support platform 7 is equipped with an air pressure support 9. The rear of the machine tool electrical cabinet 1 is equipped with an air pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com