Drilling equipment for heat exchanger tube sheet

A technology for drilling devices and heat exchanger tubes, which is applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of reduced hole position accuracy, low production efficiency, fatigue, etc., and achieve The effect of reducing the number of alignment holes and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

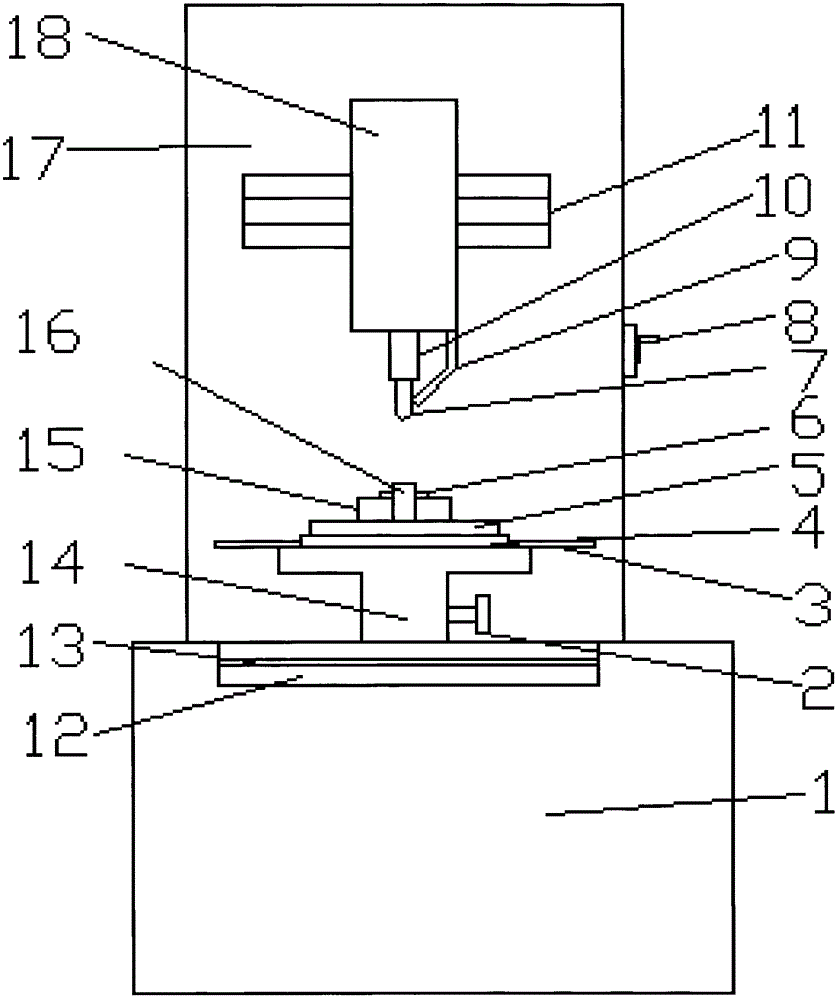

[0015] see figure 1 , in an embodiment of the present invention, a heat exchanger tube sheet drilling device, including a machine base 1, a knob 2, a handle 3, a dial 4, a tube sheet 5, a fastening pin 6, a drill bit 7, a rocker 8, a cutting Liquid pipe 9, plunger 10, side sliding guide rail 11, cutting fluid tank 12, filter screen 13, rotary table 14, pressing plate 15, threaded rod 16, fuselage 17 and drilling device 18, described base 1 is positioned at fuselage 17, the base 1 is provided with a cutting fluid tank 12, the function of the cutting fluid tank 12 is to recover and cool the cutting fluid, the cutting fluid tank 12 is provided with a filter 13, and the function of the filter 13 is to remove the metal in the cutting fluid Impurities, to prevent metal impurities from accumulating in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com