Manufacturing process of high-efficiency and energy-saving aluminum alloy fireproof window

A high-efficiency, energy-saving, manufacturing process technology, applied to fire doors, windows/doors, door/window accessories, etc., can solve problems such as safety hazards, limited heat absorption capacity, and reduced structural strength of windows to achieve enhanced strength and fire resistance , enhance fire resistance, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

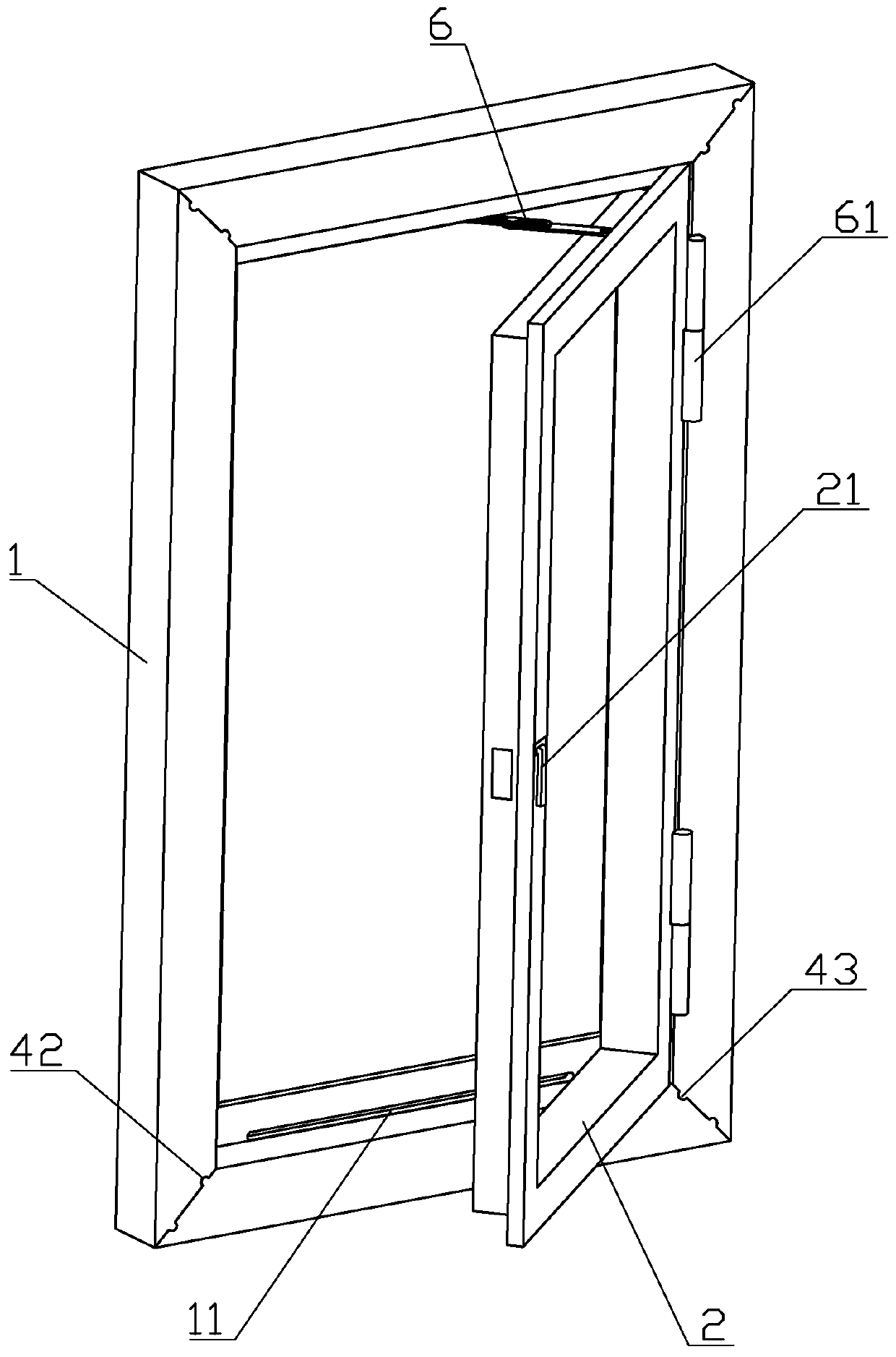

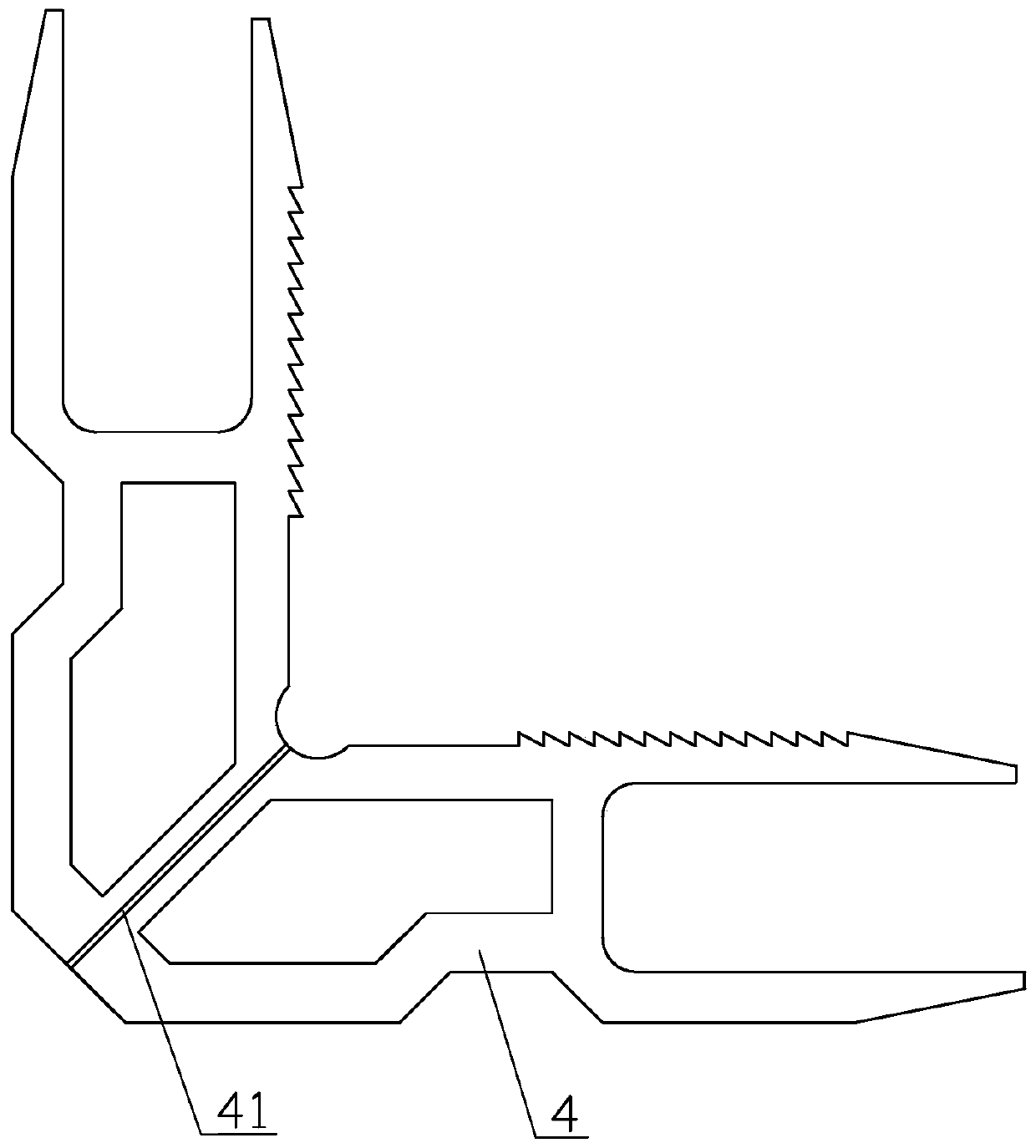

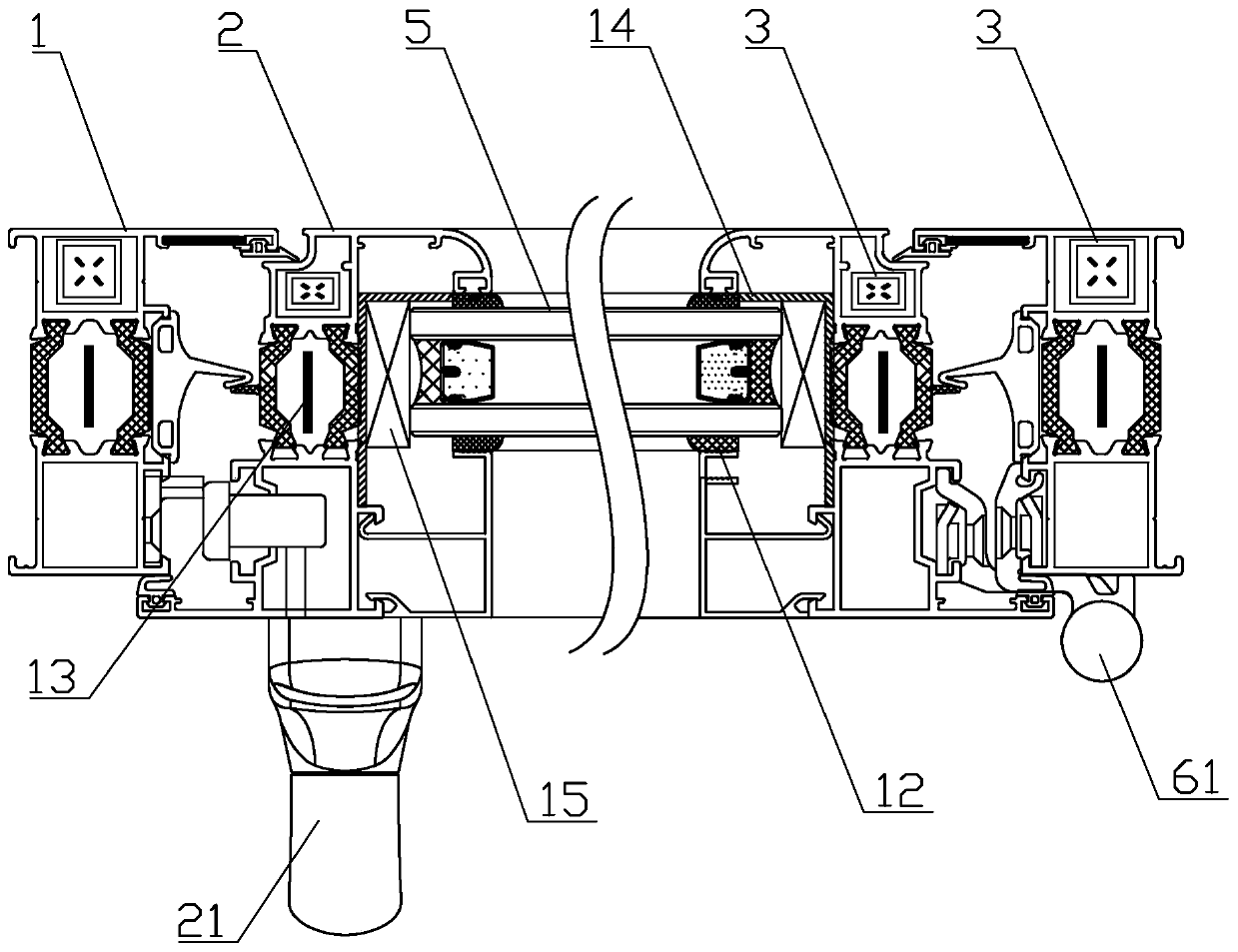

[0045] Such as figure 1 As shown, a fireproof window manufactured by a high-efficiency and energy-saving aluminum alloy fireproof window manufacturing process includes a window frame 1 and a window sash 2, both of which are rectangular closed frames surrounded by a plurality of frame profiles, and the window sash 2- The side is hinged with the window frame 1. combine figure 2 As shown, there is a corner code 4 between two adjacent frame profiles of the window frame 1 and the sash 2, and the corner code 4 is used to adjust the verticality of the frame profiles; the surface of the corner code 4 is provided with a wire groove 41 along the direction of its symmetry axis. A semicircular groove 42 and a semicircular block 43 are provided on the edge of each frame profile, and the semicircular groove 42 and the semicircular block 43 between two adjacent frame pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com