High-toughness super-wear-resistance artificial bone for repairing bone defects and preparation method thereof

An artificial bone, high toughness technology, applied in medical science, prosthesis, coating, etc., can solve the problems of high cost, troublesome revision surgery, etc., and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

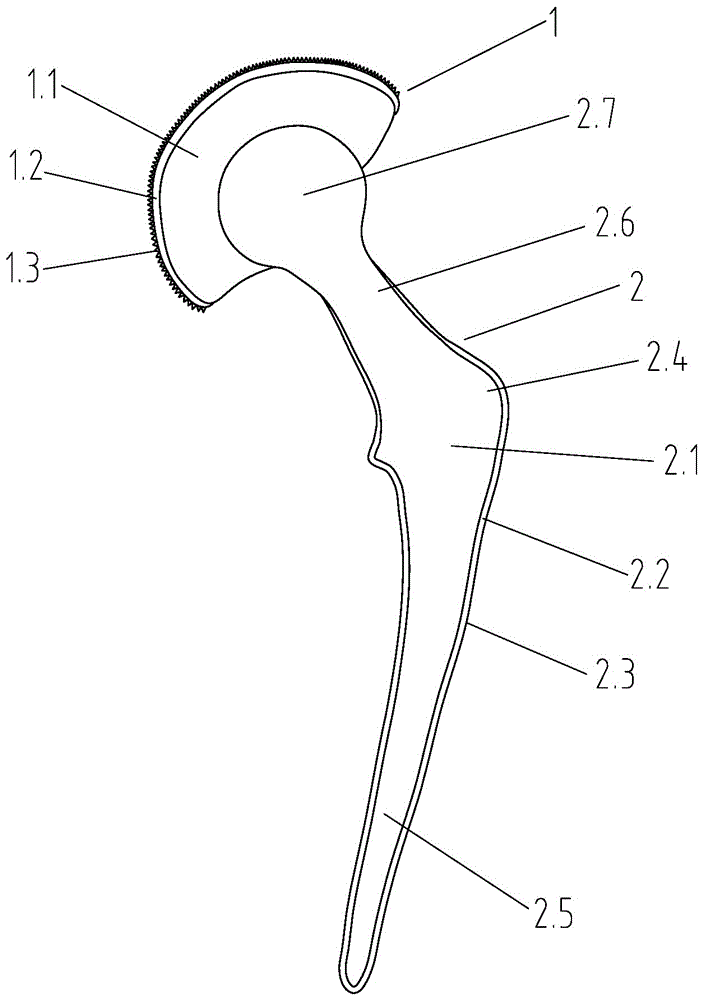

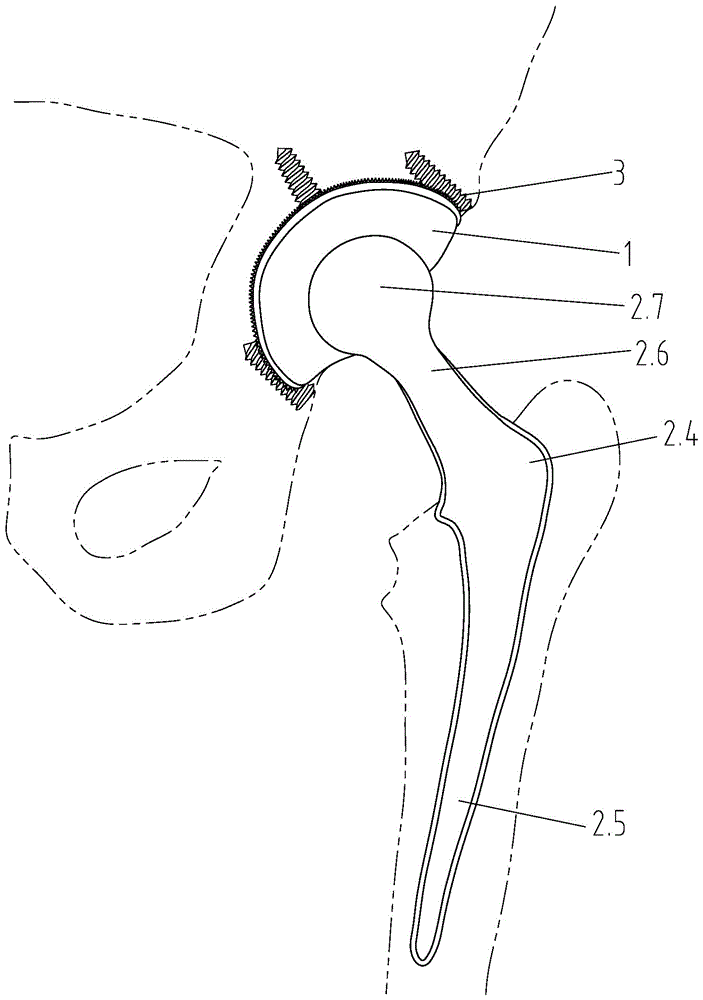

[0032] Embodiment one: when artificial bone of the present invention is made into artificial bone hip joint figure 1 As shown, the artificial bone hip joint includes an artificial acetabular 1 and an artificial femur 2. The bracket 1.1 of the artificial acetabular 1 is made of a composite material of PEEK resin, barium glass fiber and calcium carbonate whiskers. The barium glass fiber is added for X-ray Development and adjustment adjust the modulus of elasticity, and calcium carbonate whiskers are added to increase wear resistance. The bracket 1.1 of the artificial acetabulum 1 is wrapped with a layer of artificial acetabular dense layer 1.2 formed by sintering hardened bioactive glass ceramics, and an artificial acetabular layer made of bioactive glass ceramics is attached to the surface of the artificial acetabular dense layer 1.2 The porosity layer 1.3 has a porosity of 30-60VOL%, and a cell diameter of 100-1000μm, which facilitates the growth of Harvard's nutrient tubes an...

Embodiment 2

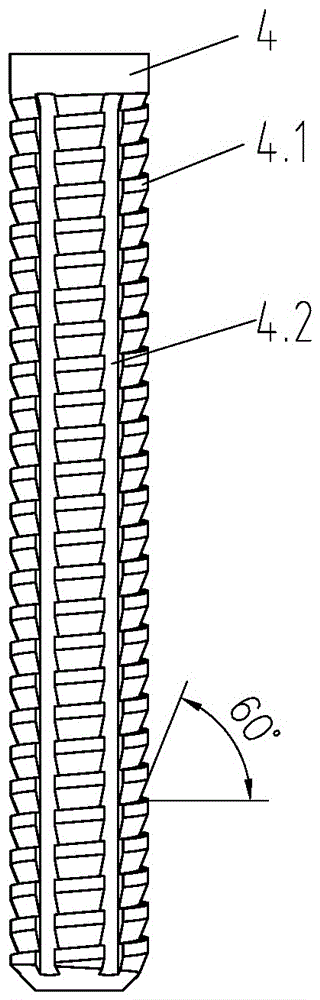

[0034] Embodiment two: when artificial bone of the present invention is made into artificial intramedullary nail image 3 As shown, the bracket of the artificial intramedullary nail 4 is made of a composite material of PEEK resin, barium glass fiber and calcium carbonate whiskers, and the outside of the artificial intramedullary nail 4 is wrapped with a dense layer formed by sintering hardened bioactive glass ceramics. A porous layer made of bioactive glass ceramics is also attached on the surface of the dense layer, with a porosity of 30-60VOL% and a cell diameter of 10-200μm. The outside of the artificial intramedullary nail 4 is provided with trapezoidal screw teeth 4.1, the front slope of the trapezoidal screw teeth is a 60° slope, and the outside of the artificial intramedullary nail 4 is also provided with 6 longitudinal grooves, and the 6 longitudinal grooves are evenly distributed along the outer circumference. Cut off the trapezoidal thread.

[0035] The use of this ...

Embodiment 3

[0036] Embodiment three: when artificial bone of the present invention is made femoral intramedullary nail Figure 5 with Image 6 As shown, the bracket of the femoral intramedullary nail 5 is made of a composite material of PEEK resin, barium glass fiber and calcium carbonate whiskers. The surface of the dense layer is also attached with a porous layer made of bioactive glass ceramics, with a porosity of 30-60VOL% and a cell diameter of 10-200μm. Both ends of the femoral intramedullary nail 5 are provided with pin holes 5.1, and pin holes 5.1 are equipped with pins 5.2.

[0037] The application of this femoral intramedullary nail in femur comminuted fracture is as follows: Figure 7 As shown, the specific operation is: general anesthesia, lie supine on the orthopedic traction bed, with the affected limb at 15°, use C-arm X-ray fluoroscopy, it is best to achieve alignment, find the entrance of the apex of the greater trochanter, and place the guide needle to enter After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com