Alkali-proof and temperature-resistant PVA (Polyvinyl Alcohol) fiber and purpose thereof

A fiber and alkali-resistant technology, applied in the field of alkali-resistant PVA fiber and high temperature resistance, can solve the problems of not satisfying both high temperature resistance and alkali resistance, PVA fiber shrinkage or even decomposition, and mechanical properties cannot be guaranteed, and achieve high temperature resistance, Good dispersibility and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

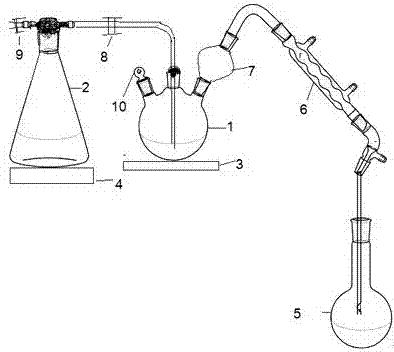

Method used

Image

Examples

Embodiment 1

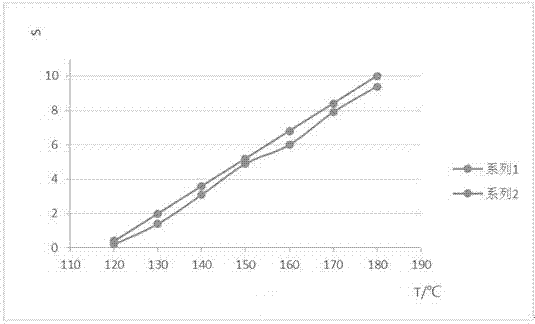

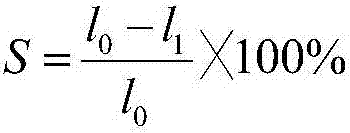

[0045] Example 1: PVA with a degree of polymerization of 1500 and a degree of alcoholysis of 95% (mol) is dissolved successively, spinned, coagulated in a coagulation bath, wet-heat stretched, heat-set, and then the fiber is subjected to secondary hydroformylation at normal temperature. For the first time, glutaraldehyde was used for hydroformylation, and the hydroformylation solution was composed of glutaraldehyde, concentrated sulfuric acid, zinc chloride and water, wherein the concentration of glutaraldehyde was 80g / L, the concentration of concentrated sulfuric acid was 220g / L, and the concentration of zinc chloride The concentration is 30g / L, the temperature of the formaldehyde solution is 75°C, the time of formaldehyde is 45 minutes, and formaldehyde is used for the second time. The formaldehyde solution is composed of formaldehyde, concentrated sulfuric acid, sodium sulfate and water, and the concentration of formaldehyde is 40g / L , the concentration of concentrated sulfu...

Embodiment 2

[0047] Example 2: PVA with a degree of polymerization of 2000 and a degree of alcoholysis of 90% (mol) is dissolved successively, spinned, coagulated in a coagulation bath, wet-heat stretched, heat-set, and then the fibers are subjected to secondary hydroformylation. The binary aldehyde used in the first hydroformylation is a combination of glutaraldehyde and glyoxal, and the hydroformylation solution is composed of glutaraldehyde, glyoxal, concentrated sulfuric acid, zinc chloride and water, wherein glutaraldehyde and The total concentration of dialdehyde in the hydroformylation solution is 90g / L, the concentration of concentrated sulfuric acid is 180g / L, the concentration of zinc chloride is 60g / L, the temperature of the hydroformylation solution is 65°C, and the hydroformylation time is 25 minutes. Glutaraldehyde and The molar ratio of glyoxal is 7:3, the aldehyde used for the second time is a composition of formaldehyde and acetaldehyde, and the formaldehyde solution is com...

Embodiment 3

[0049] Example 3: PVA with a degree of polymerization of 2400 and a degree of alcoholysis of 99.5% (mol) was dissolved successively, spinned, coagulated in a coagulation bath, wet-heat stretched, heat-set, and then the fiber was subjected to secondary hydroformylation at normal temperature. The aldehyde used for the first hydroformylation is a combination of glutaraldehyde and adipaldehyde, and the hydroformylation solution is composed of glutaraldehyde, adipaldehyde, concentrated sulfuric acid, zinc chloride and water, wherein glutaraldehyde and adipaldehyde are in the aldehyde The total concentration in the hydroformylation solution is 50g / L, the concentration of concentrated sulfuric acid is 170g / L, the concentration of zinc chloride is 80g / L, the temperature of the hydroformylation solution is 80°C, the hydroformylation time is 35 minutes, the moles of glutaraldehyde and adipaldehyde The ratio is 7:3, the aldehyde used for the second time is a composition of formaldehyde an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com