Anti-corrosion scalpel handle and preparation method thereof

A scalpel and corrosion-resistant technology, applied in dissection instruments, etc., can solve problems such as being easily corroded, and achieve the effect of good corrosion resistance and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

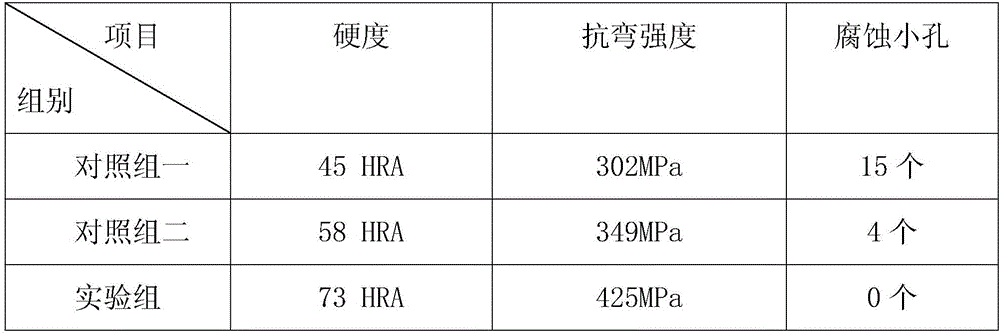

Examples

Embodiment 1

[0020] A method for preparing a corrosion-resistant scalpel handle, comprising the following raw materials in proportions by weight: 102 parts of aluminum, 110 parts of magnesium, 60 parts of silver, 2 parts of manganese, 1 part of cerium, 1 part of thorium, and 2 parts of zirconium silicate 4 parts of chromium trioxide, 1 part of yttrium oxide, 4 parts of tungsten carbide, 6 parts of cubic boron nitride, 1 part of tantalum carbide, 1 part of titanium sponge, 1 part of magnesium chloride, 2 parts of magnesium carbonate, 1 part of manganese chloride , 1 part of silver chloride, 1 part of hexachloroethane, 2 parts of tungsten hexachloride and 2 parts of sodium fluorosilicate.

[0021] A method for preparing a corrosion-resistant scalpel handle comprises the following steps:

[0022] 1) Preheat the resistance furnace to 500-550°C, then put in 102 parts of aluminum, 110 parts of magnesium and 60 parts of silver, and heat at the same time with argon protection. After the pure mater...

Embodiment 2

[0030] A corrosion-resistant scalpel handle and a preparation method thereof, comprising the following raw materials in proportions by weight: 100 parts of aluminum, 120 parts of magnesium, 62 parts of silver, 4 parts of manganese, 3 parts of cerium, 3 parts of thorium, and zirconium silicate 4 parts, 6 parts of chromium trioxide, 3 parts of yttrium oxide, 6 parts of tungsten carbide, 8 parts of cubic boron nitride, 3 parts of tantalum carbide, 3 parts of titanium sponge, 3 parts of magnesium chloride, 4 parts of magnesium carbonate, 3 parts of manganese chloride 3 parts of silver chloride, 3 parts of hexachloroethane, 4 parts of tungsten hexachloride and 4 parts of sodium fluorosilicate.

[0031] A method for preparing a corrosion-resistant scalpel handle, comprising the following steps:

[0032] 1) Preheat the resistance furnace to 500-550°C, then put in 100 parts of aluminum, 120 parts of magnesium and 62 parts of silver, heat at the same time and pass in argon protection, ...

Embodiment 3

[0039] A corrosion-resistant scalpel handle and a preparation method thereof, comprising the following raw materials in proportions by weight: 101 parts of aluminum, 115 parts of magnesium, 61 parts of silver, 3 parts of manganese, 2 parts of cerium, 2 parts of thorium, and zirconium silicate 3 parts, 5 parts of chromium trioxide, 2 parts of yttrium oxide, 5 parts of tungsten carbide, 7 parts of cubic boron nitride, 2 parts of tantalum carbide, 2 parts of titanium sponge, 2 parts of magnesium chloride, 3 parts of magnesium carbonate, 2 parts of manganese chloride 2 parts of silver chloride, 2 parts of hexachloroethane, 3 parts of tungsten hexachloride and 3 parts of sodium fluorosilicate.

[0040] A method for preparing a corrosion-resistant scalpel handle, comprising the following steps:

[0041]1) Preheat the resistance furnace to 500-550°C, then put in 101 parts of aluminum, 115 parts of magnesium and 61 parts of silver, heat at the same time and pass in argon protection, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com