Glass fiber plate or profile or pipe and forming device

A technology for glass fiber and forming equipment, which is applied in the field of glass fiber sheet or profile or pipe and forming equipment to achieve the effects of reducing equipment cost, improving production efficiency and easy forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

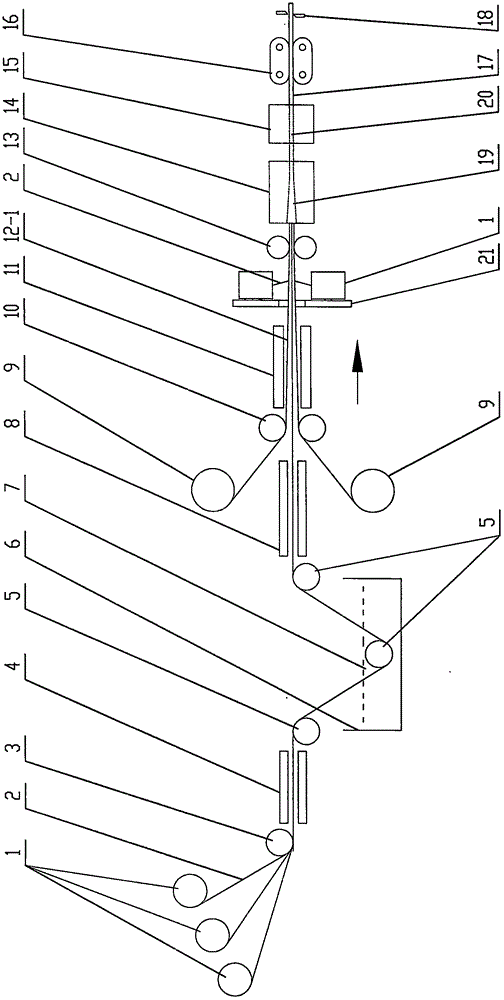

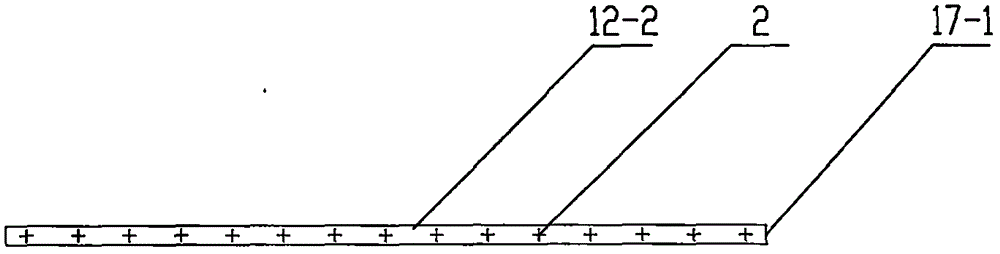

[0039] Example 1: Such as Figure 3~7 As shown, the present invention will be further explained below in conjunction with the drawings. A glass fiber sheet or profile or pipe. The surface of the glass fiber filament 2 is sequentially wrapped with a surface treatment agent 7 and a thermoplastic resin 12-2; the glass fiber filament 2 runs along the plate 17-1 or the profile 17-2 or the pipe 17-3 The length (longitudinal) direction of the glass fiber is arranged, or the glass fiber filaments 2 are arranged along the width (transverse) direction of the plate 17-1, and are arranged uniformly or in multiple bundles in the above longitudinal and transverse cross-sections;

[0040] The surface treatment agent 7 is one of the following: epoxy resin, bismaleimide, thermosetting polyimide, phenolic resin, cyanate ester resin, unsaturated polyester, lubricant, antioxidant, coupling agent , Or two or more of the above resins; the surface treatment agent impregnates the glass fiber filament 2,...

Embodiment 2

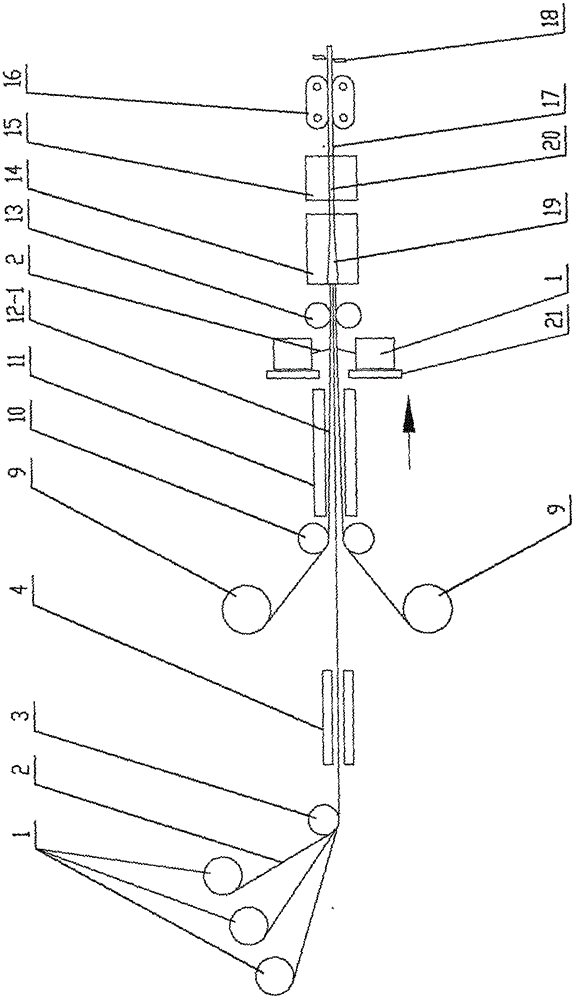

[0062] Example 2, such as figure 2 , 3 , 4, 5, 6, 7, and different from Example 1, the surface treatment agent 7 has been coated on the surface of the glass fiber filament 2 by the manufacturer, and the surface treatment agent 7 is one of the following One: epoxy resin, bismaleimide, thermosetting polyimide, phenolic resin, cyanate ester resin, unsaturated polyester, lubricant, antioxidant, coupling agent, or two or more of the above resins; The surface tension of the impregnated glass fiber filament 2 is increased, and the affinity with the thermoplastic resin 12-2 is increased, which improves the bonding strength of the two; the equipment omits the impregnation device, the second heating device 8, and other components and connection relations and implementation Example 1 is the same.

[0063] A forming equipment for producing glass fiber sheets or profiles or pipes. The equipment in turn includes a plurality of glass filament unwinding devices, a first guide roller 3, a plural...

Embodiment 3

[0071] Example 3, such as Figure 1~7 As shown, the difference from Embodiments 1 and 2 is that a glass fiber sheet or profile or pipe forming equipment also includes a saw blade cutting device 18, which can be cut to a fixed length. The other composition and connection relationship are the same as those in the first and second embodiments.

[0072] Preferably, a glass fiber sheet or profile or pipe forming equipment, the heaters of the first heating device 4, the second heating device 8, and the third heating device 11 are infrared or resistance heaters, and the infrared heaters heat The device has fast radiation, strong penetrating power, fast heating and energy saving.

[0073] Preferably, a glass fiber sheet or profile or pipe forming equipment further includes a plurality of guide rollers 13 located on the right side of the third heating device 11, which are effective for the glass fiber filament 2 and the filament or strip film 12-1. Straighten out and guide the role.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com