Coal bed gas U-shaped well staged fracturing exploitation technology

A staged fracturing and coalbed methane technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as pollution, high formation crack initiation pressure, and insufficient fracture width, and achieve simplified drainage process , increase the seepage velocity, reduce the effect of crack initiation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

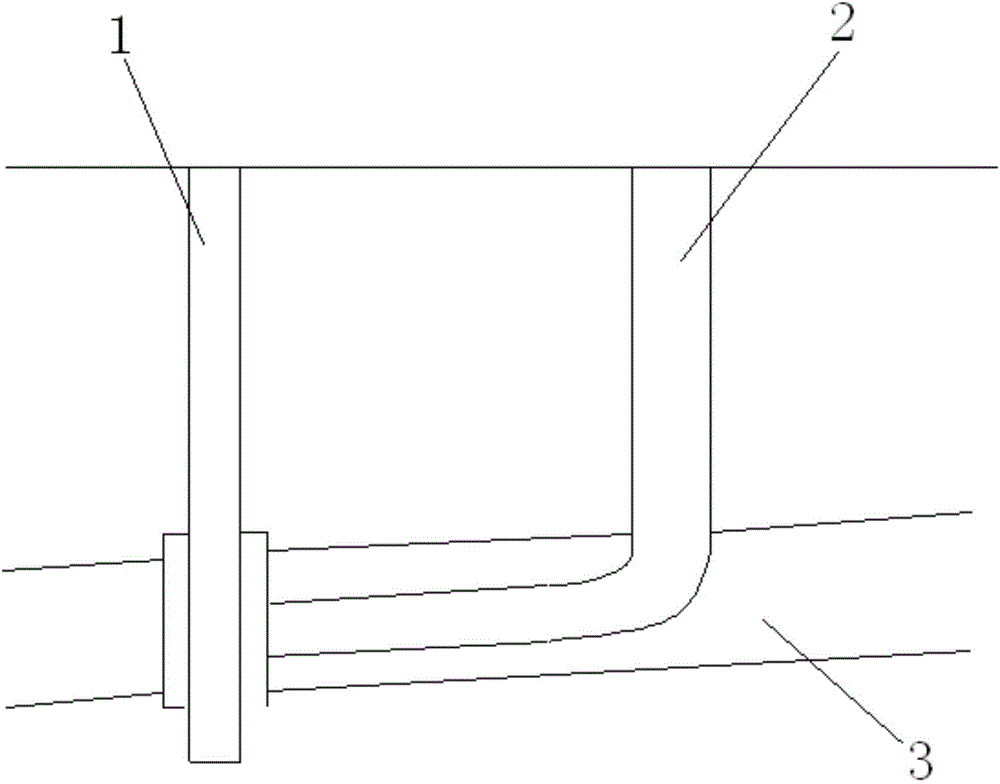

[0013] like figure 1 Shown, a U-shaped coalbed methane well staged fracturing mining technology, the technical steps are as follows:

[0014] 1. Drilling and completion of U-shaped well: U-shaped well is composed of a vertical well and a horizontal well. The vertical well is drilled first, and then the horizontal well is drilled. Among them, the horizontal well is located at the high part of the structure of the target layer, and the vertical well is located at the low part of the structure; when the vertical well is drilled, casing cementing is used, and holes are reamed in the target interval of the horizontal well. The diameter of the cave is 0.5m. Main borehole cementing, after connection, fill sand in the cave made in the vertical well, the sand filling depth should be higher than the top surface of the cave created, after sand filling, put cement plug on it, after the pressure test is qualified, run the casing in the main borehole of the horizontal well Cementing: After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com