Fracturing process for enhancing low permeability reservoir deliverability

A high-energy gas fracturing and reservoir technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as affecting post-fracture productivity, reducing permeability of low-permeability reservoirs, and blocking pore space, etc. To achieve the effect of reducing damage, increasing oil drainage area, and increasing post-pressing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Example 1: Well Zhuang 71-28

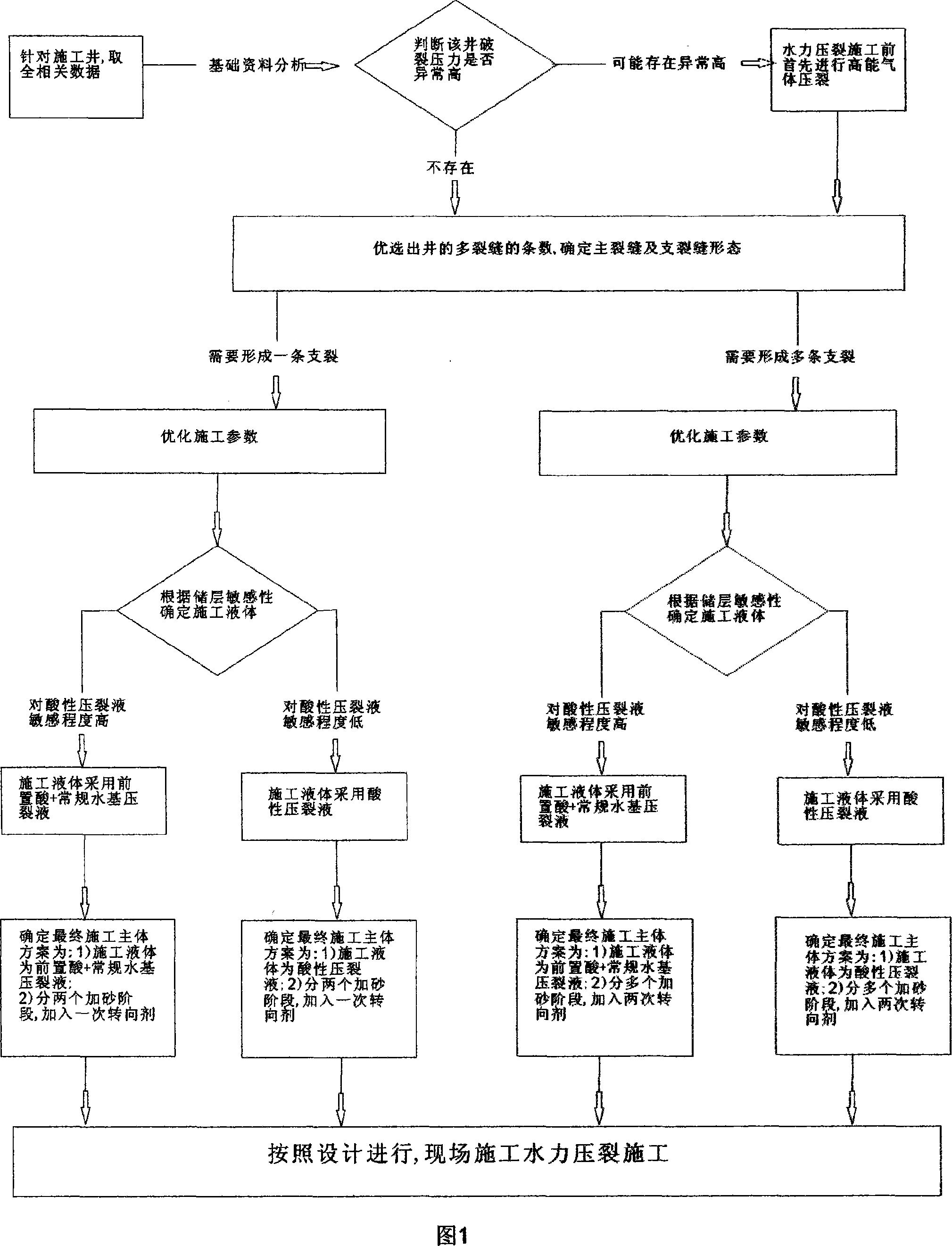

[0039] The reservoir depth of this well is 2156m, and the reservoir permeability is 0.95×10 -3 μm 2 , porosity 11.37%, typical low-pressure tight oil reservoir, no fracturing and no industrial oil flow. In order to achieve the combination of fracturing primary fractures and secondary fractures, increase the drainage area of artificial fractures, and increase the productivity of oil wells as much as possible, the reservoir stimulation adopts pre-acid fracturing + intra-fracture steering fracturing technology.

[0040] I. The specific method is:

[0041] 1. The fracture pressure of this well is predicted to be 42MPa through formula calculation, and the statistical data in this area show that the normal average fracture pressure is 43MPa, so this well does not need high-energy gas fracturing.

[0042] 2. Single top seal fracturing string is used in hydraulic fracturing construction; Y344 type packer is used.

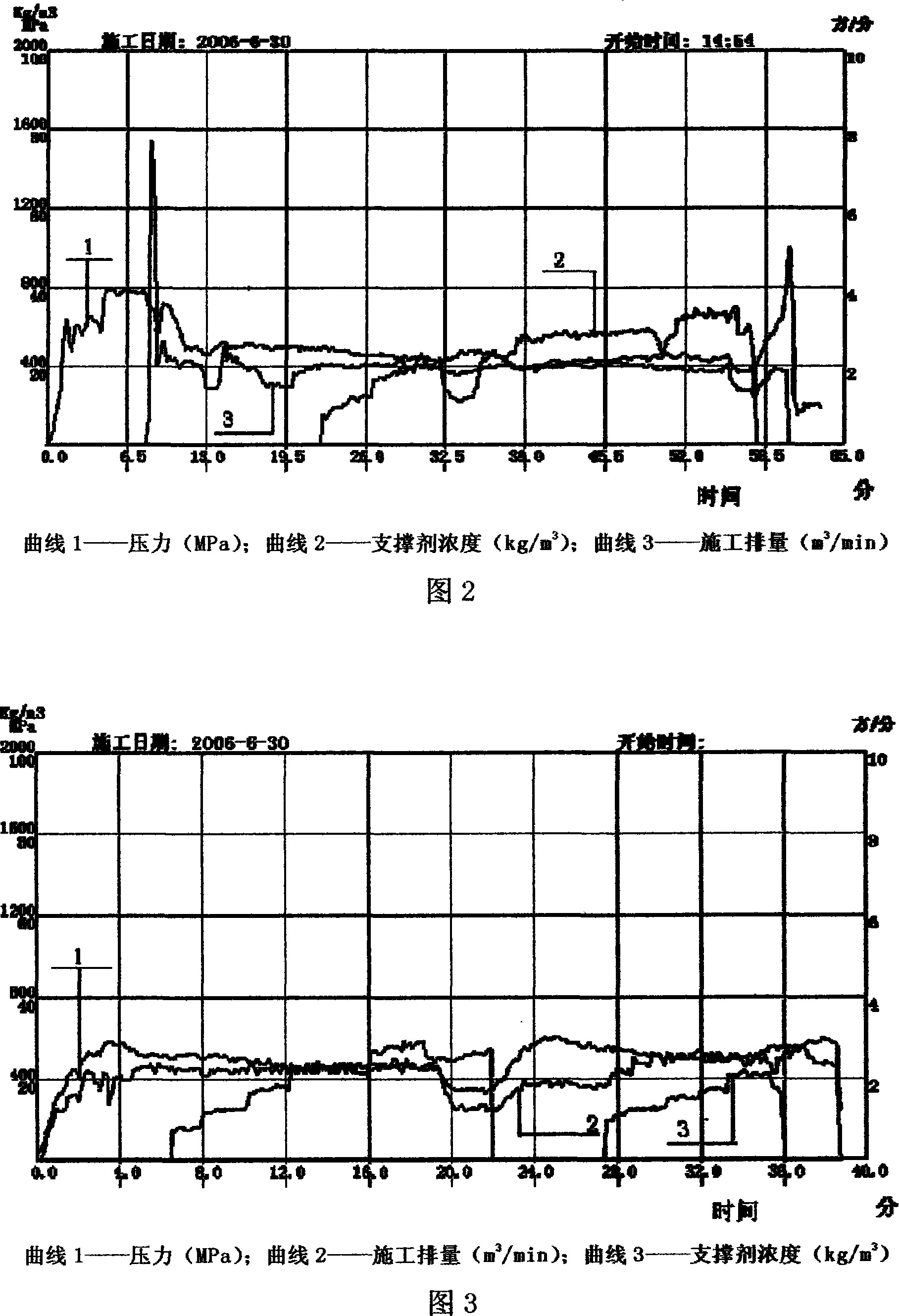

[0043] 3. Through the anal...

example 2

[0064] Example 2: Well 67-56

[0065] The buried depth of the oil layer in this well is 1975m, and the electrical permeability of the reservoir is 2.2×10 -3 μm 2 , with a porosity of 10.85%, located at the edge of the block. Compared with the reservoirs in the same block, the reservoir conditions are poorer, the lithology is tighter, and the physical properties are poor. It is predicted that the daily oil production of this well is only 15m3 under conventional fracturing 3 , in order to increase the production capacity after pressing, this process is implemented.

[0066] The specific method is:

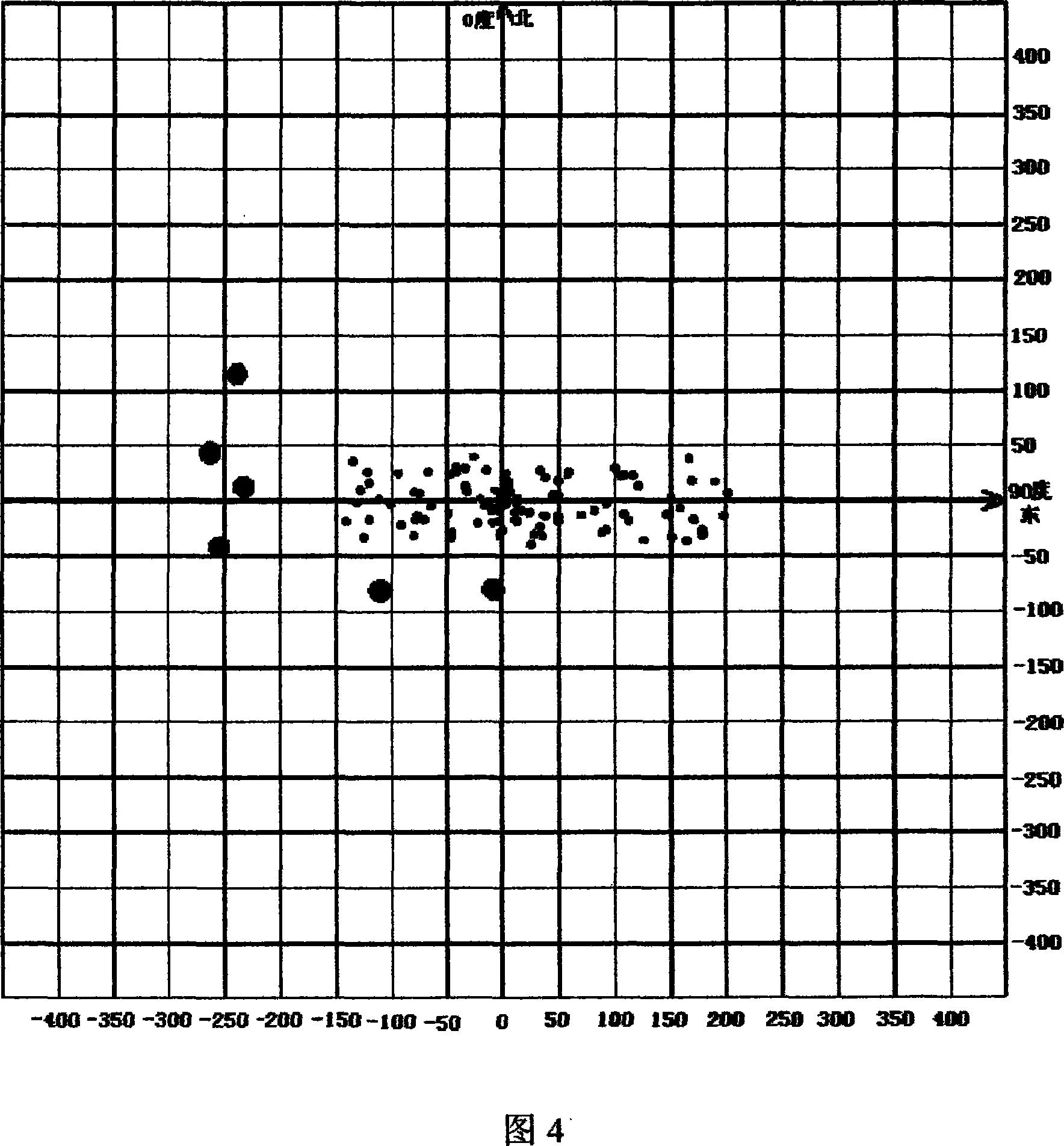

[0067] 1. The fracture pressure of the well is determined to be 45MPa through prediction, and the statistical fracture pressure in this area is 38MPa, so the well is firstly subjected to high-energy gas fracturing.

[0068] 2. Considering that the perforation section of the well is 3m, the amount of high-energy gas ammunition in the well is determined to be 50kg.

[0069] 3. Hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com