Twin screw breaking and dehydrating integrated processing equipment with gear pump

A processing equipment and gear pump technology, applied in grain processing, manufacturing tools, presses, etc., can solve the problem of low production efficiency of filter presses, and achieve the effect of simple structure and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

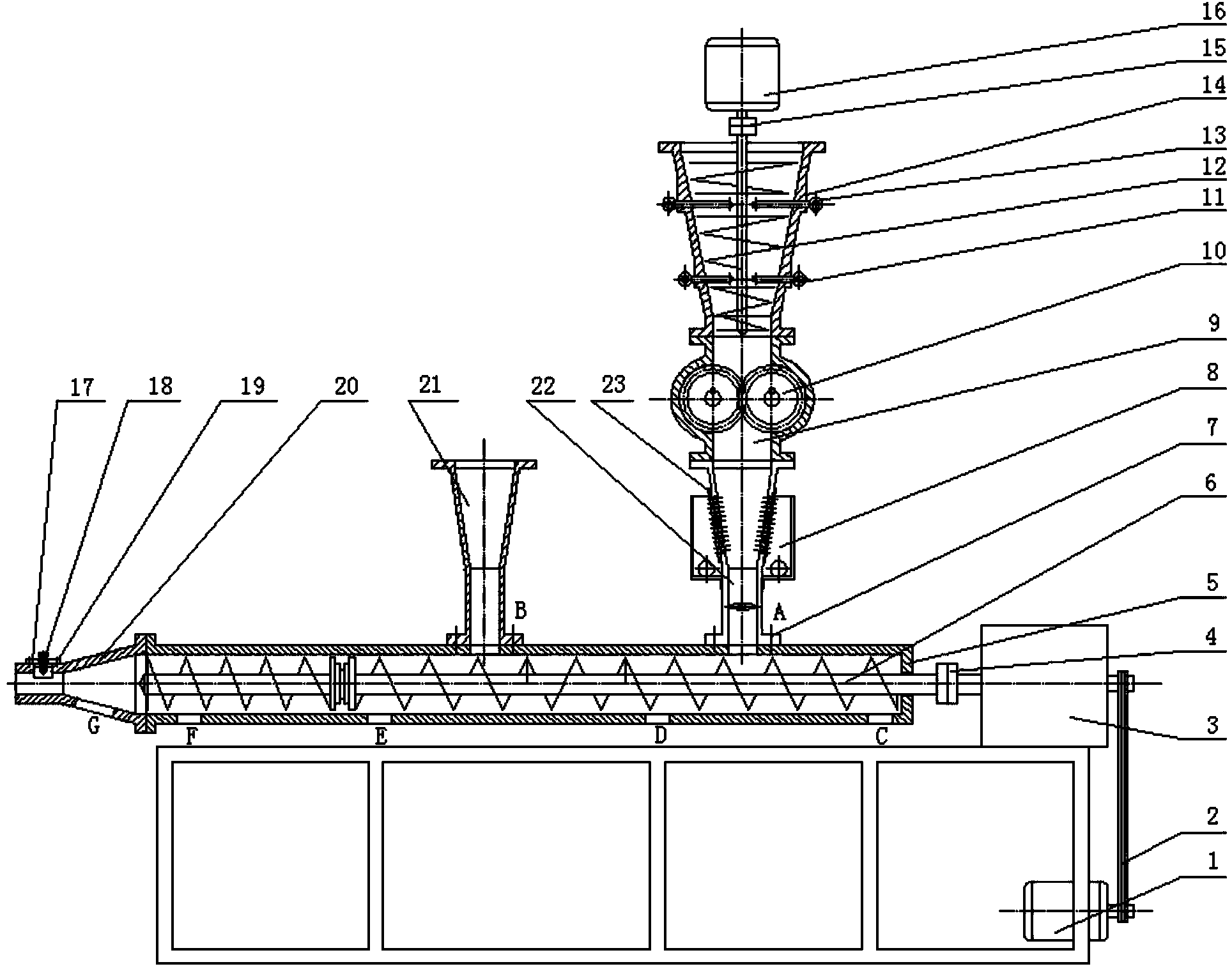

[0033] Fig. 1 is an embodiment of the present invention, which is used for liquid extraction of tuber plants. The main motor, reduction gear mechanism and barrel pair are fixed on the frame, the main motor is connected with the reduction gear mechanism through a belt transmission device, the two output shafts of the reduction gear mechanism are connected to the two combined screw pairs installed in the barrel pair Connected by a coupling, the combined screw pair extends into the barrel pair, and the screw root is sealed with a screw dynamic seal. The barrel outlet on the other side of the barrel pair is connected to the dehydration head, and the dehydration head controls the opening degree by adjusting the upper and lower positions of the damping block, thereby adjusting the pressure of the water-containing material in the head and the barrel.

[0034] In this example, the dehydration ports C, D, E, F, and G adopt a separate design, and the diameter of the filter hole is 3 mm....

Embodiment 2

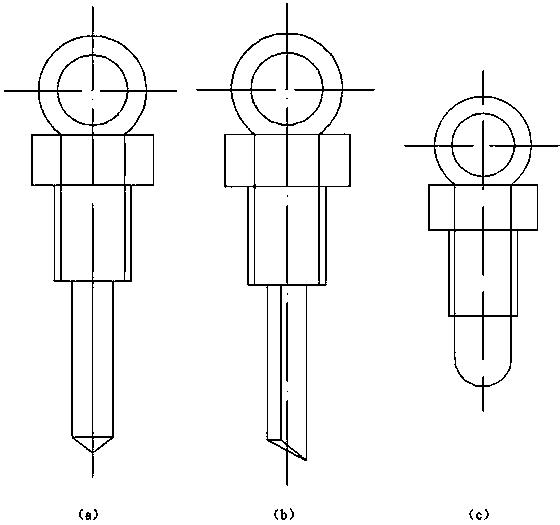

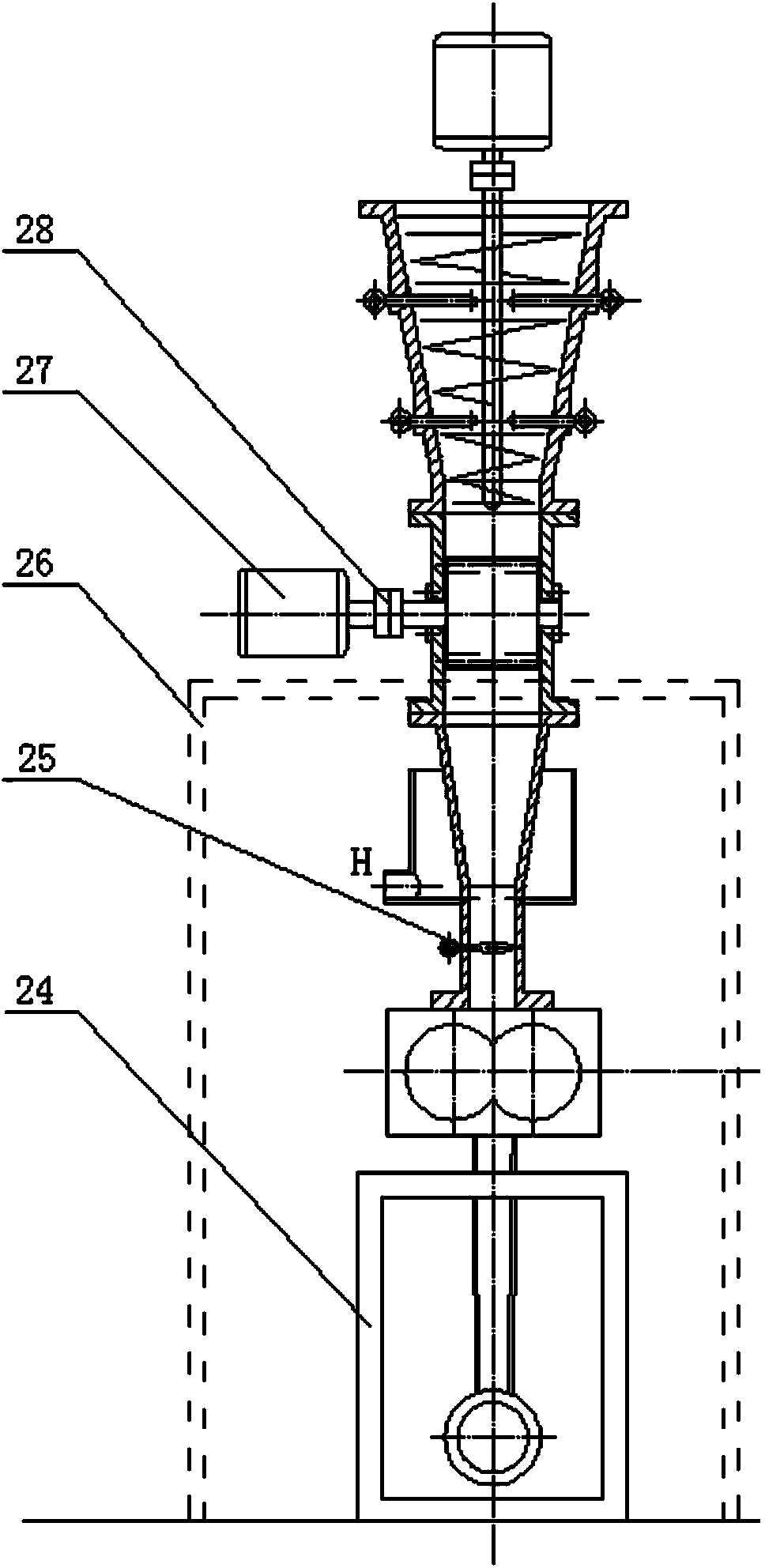

[0042] Fig. 3 is Embodiment 2 of the present invention, which is used for dehydrating materials with high water content and high fluidity. The difference between embodiment 2 and embodiment 1 is that embodiment 2 does not need to set a crushing knife in the forced feeder part because it does not need to crush the material, so use such as Figure 4 The block shown in (c) blocks the threaded hole of the crushing knife. The gear pair of the gear pump is a pair of gears meshing with each other, the diameter of the gear is 300mm, and the input shaft of the driving wheel is connected with the gear pump motor through a coupling. The upper end of the gear pump is connected with the forced feeder, and the lower end is connected with the upper filter cartridge.

[0043] Upper filter cartridge Two detachable upper filter cartridge filter plates with a filter hole diameter of 3 mm and a replaceable filter screen attached to the filter plate. Feeding port B mainly plays the role of exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com