Porous sandstone reservoir permeability-enhancing sand-stabilizing acidizing compound working solution as well as preparation method and application thereof

A working fluid and reservoir technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of unfavorable loose sandstone reservoirs such as increasing seepage and stabilizing sand, so as to slow down the reaction of fluoboric acid and improve The effect of increasing production capacity and increasing penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

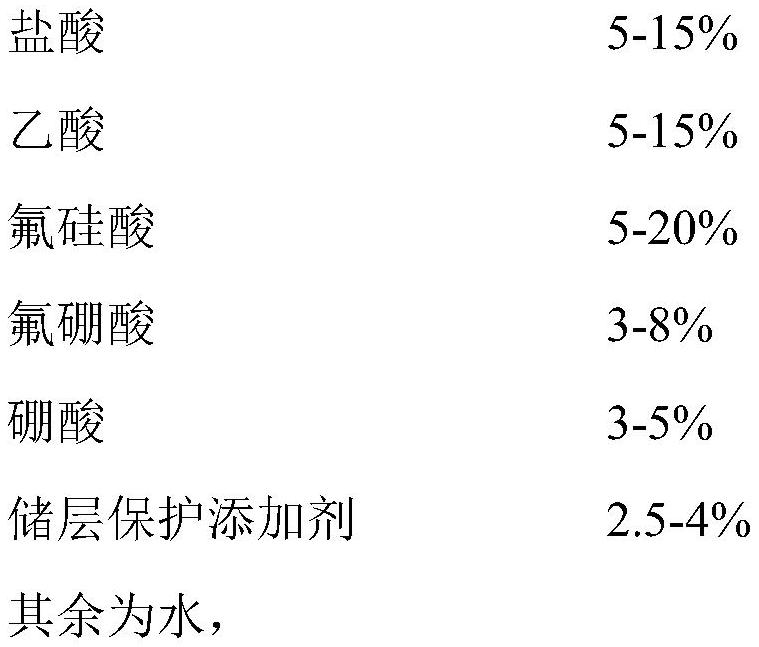

[0034] In the present embodiment, the osmotic stabilized sand acidification composite working liquid of the loose sandstone reservoir (according to the configuration of 1000kg), the component weight is kg:

[0035]

[0036]

[0037] Among them, the organic cationic polymer anti-expansion agent and the cycloalkyl imidazoline corrosion inhibitor were purchased from Tianjin Tiancheng Chemical Co., Ltd. or Shandong Deshi Chemical Co., Ltd.

[0038] In the acid-resistant stirring reaction tank, a sufficient amount of water is added, the above-mentioned industrial raw materials are placed in accordance with industrial hydrochloric acid, acetic acid, fluorosilic acid, fluoroboric acid, boric acid, glycol monobutyl ether, polyethoxylated fatty alcohol, organic cationic polymer, cycloalkyl imidazoline in the order of acid-resistant stirring reaction tank, evenly stirred for 30-60 minutes, the acid is filtered to obtain the finished working liquid.

Embodiment 2

[0040] In the present embodiment, the osmotic stabilized sand acidification composite working liquid of the loose sandstone reservoir (according to the configuration of 1000kg), the component weight is kg:

[0041]

[0042] Among them, the organic cationic polymer anti-expansion agent and the cycloalkyl imidazoline corrosion inhibitor were purchased from Tianjin Tiancheng Chemical Co., Ltd. or Shandong Deshi Chemical Co., Ltd.

[0043] The above industrial raw materials are put into the acid-resistant stirring reaction tank in accordance with the order of industrial hydrochloric acid, acetic acid, fluorosilic acid, fluoroboric acid, boric acid, glycol monobutyl ether, polyethoxylated fatty alcohol, organic cationic polymer, cycloalkyl imidazoline, and evenly stirred for 30-60 minutes, and the acid is filtered to obtain a finished working liquid.

Embodiment 3

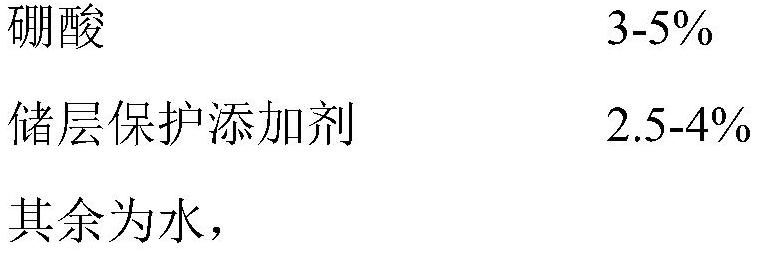

[0045] In the present embodiment, the osmotic stabilized sand acidification composite working liquid of the loose sandstone reservoir (according to the configuration of 1000kg), the component weight is kg:

[0046]

[0047] Among them, the organic cationic polymer anti-expansion agent and the cycloalkyl imidazoline corrosion inhibitor were purchased from Tianjin Tiancheng Chemical Co., Ltd. or Shandong Deshi Chemical Co., Ltd.

[0048] In the acid-resistant stirring reaction tank, a sufficient amount of water is added, the above-mentioned industrial raw materials are placed in accordance with industrial hydrochloric acid, acetic acid, fluorosilic acid, fluoroboric acid, boric acid, glycol monobutyl ether, polyethoxylated fatty alcohol, organic cationic polymer, cycloalkyl imidazoline in the order of acid-resistant stirring reaction tank, evenly stirred for 30-60 minutes, the acid is filtered to obtain the finished working liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com