Small construction simulating device for cutter-suction type dredger

The technology of a cutter suction dredger and a simulation device, which is applied in the field of small construction simulators of a cutter suction dredger, can solve the problems of high energy consumption, long time, and high test cost, and achieve good soil adaptability and land occupation The effect of small space and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

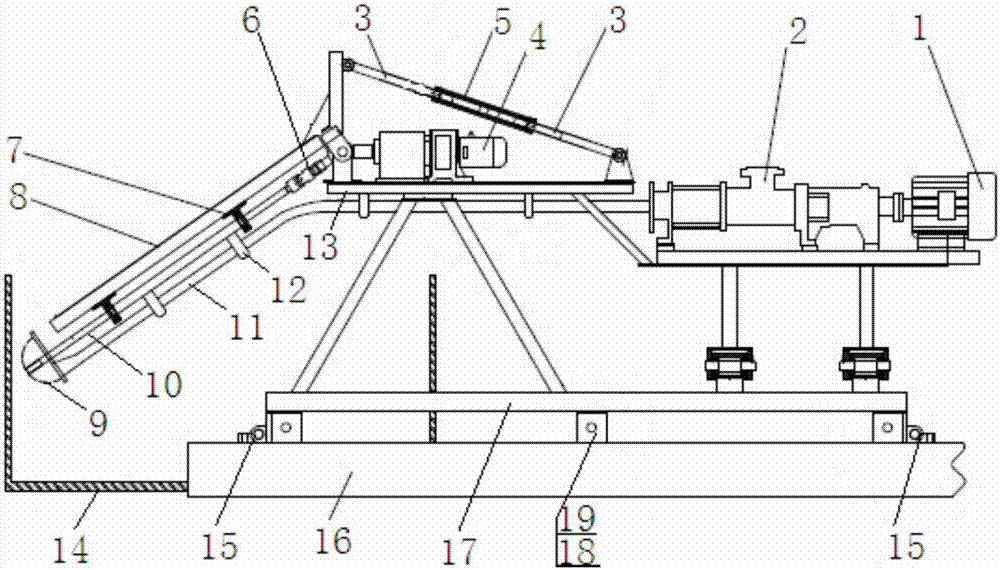

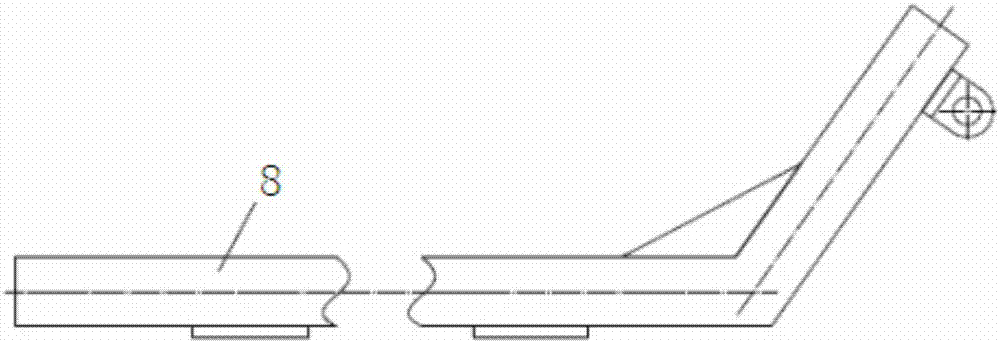

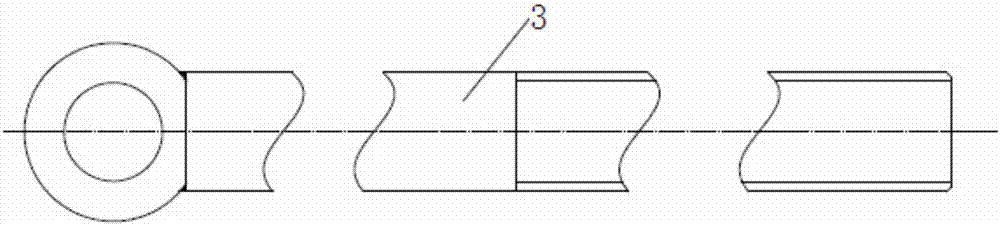

[0029] like figure 1 As shown, a small-scale construction simulation device for a cutter suction dredger includes electrical control equipment, a track 16 and a transparent and wear-resistant water tank 14. The track 16 is provided with a mobile frame 17, which is equipped with a Roller 18, the mobile motor 19 that provides power for the roller 18 (when the required torque is large, the mobile motor 19 is connected with the roller 18 through a reducer), the locking mechanism 15 that can fix the mobile frame 17, and the traverse motor 20 , the leading screw 22 that is connected with the traverse motor 20 and perpendicular to the track 16 (when the required torque is large, the traverse motor 20 is connected with the lead screw 22 through a reducer), the mud pump 2 and the mud pump 2 connected with the mud pump 2 The pump motor 1 and the lead screw 22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com