Real-time linkage intelligent control method and control model for vibroflotation pile construction

An intelligent control and linkage technology, applied in the field of vibrating, can solve the problems of high labor intensity, error-prone, cumbersome operation process, etc., achieve good construction effect, improve construction efficiency and improve construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

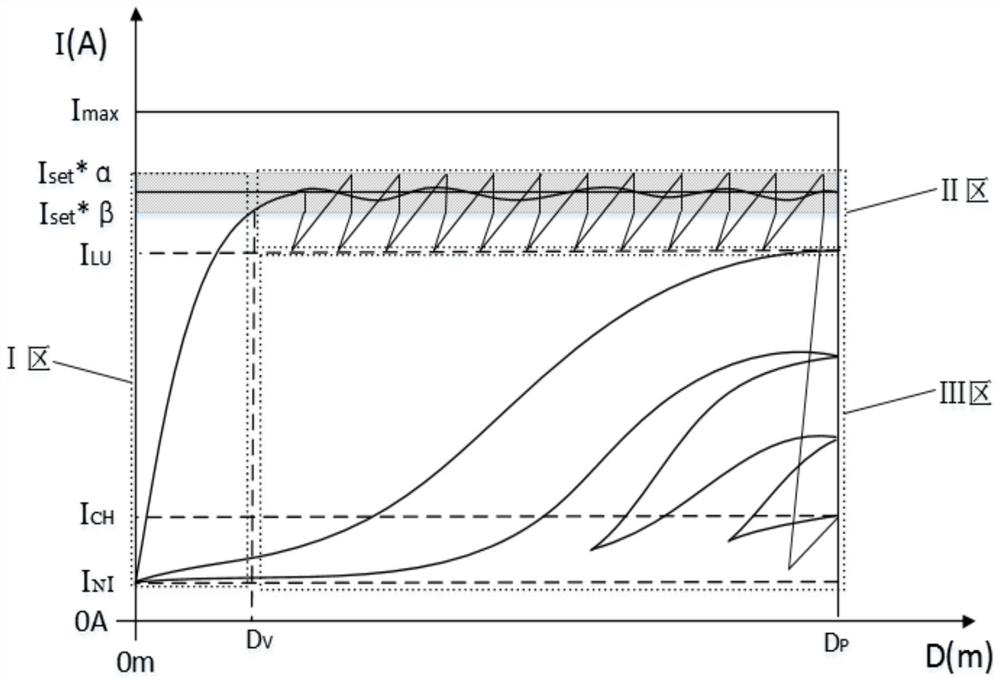

[0032] like Figure 1 to Figure 7 As shown in the figure, the real-time linkage intelligent control method for vibro-pile construction includes the following steps: establishing a functional relationship between the vibrating depth and the vibrating current, and adjusting the vibrating depth and / or the vibrating speed in real time according to the functional relationship.

[0033] The invention is convenient for intuitively depicting the optimal construction plan, monitoring the construction data in real time, obtaining the tuning plan, and optimizing the construction parameters. Therefore, the construction efficiency and construction quality are improved to a certain extent, and the construction parameters can be adjusted intelligently to achieve better construction effects. . Therefore, the problems existing in the prior art, such as relying too much on setting parameters, easily leading to low construction efficiency and poor construction quality, and being unable to perfor...

Embodiment 2

[0045] like Figure 1 to Figure 7 As shown, as a further optimization of Embodiment 1, this embodiment includes all the technical features of Embodiment 1. In addition, this embodiment also includes the following technical features:

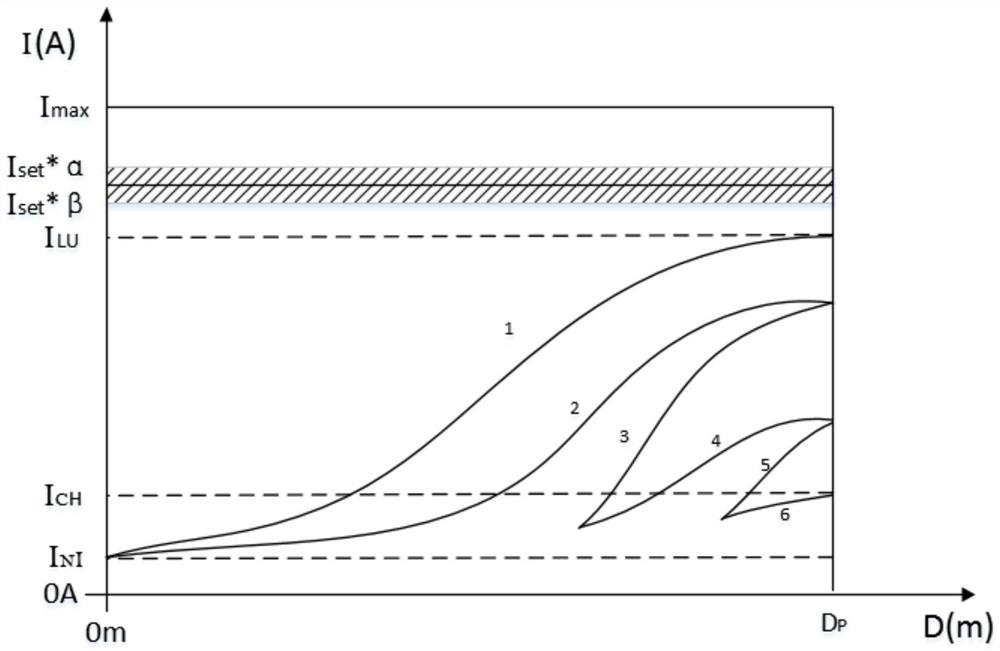

[0046] As a preferred technical solution, it also includes the following steps: when the pile making operation is performed, the vibrator is sequentially carried out in three stages of lifting, reverse insertion, and vibration retention, and then circulates until the pile making is completed.

[0047] This facilitates monitoring and control of pile making operations.

[0048] As a preferred technical solution, it also includes the following steps: when the lifting operation is performed, if the vibrator starts to lift from the bottom of the hole, the lifting is ended when the set lifting depth from the bottom of the hole is mentioned. Put the filler in and insert it backwards; if the vibrator starts to lift up from the bottom of the non-hole, wh...

Embodiment 3

[0058] like Figure 1 to Figure 7 As shown, this embodiment includes all the technical features of Embodiment 1 and Embodiment 2. On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a more detailed implementation.

[0059] It should be noted that, in the text and the corresponding drawings in this embodiment, the word current, which is not specially emphasized, refers to the vibration current; the word depth, which is not specially emphasized, refers to the vibration depth.

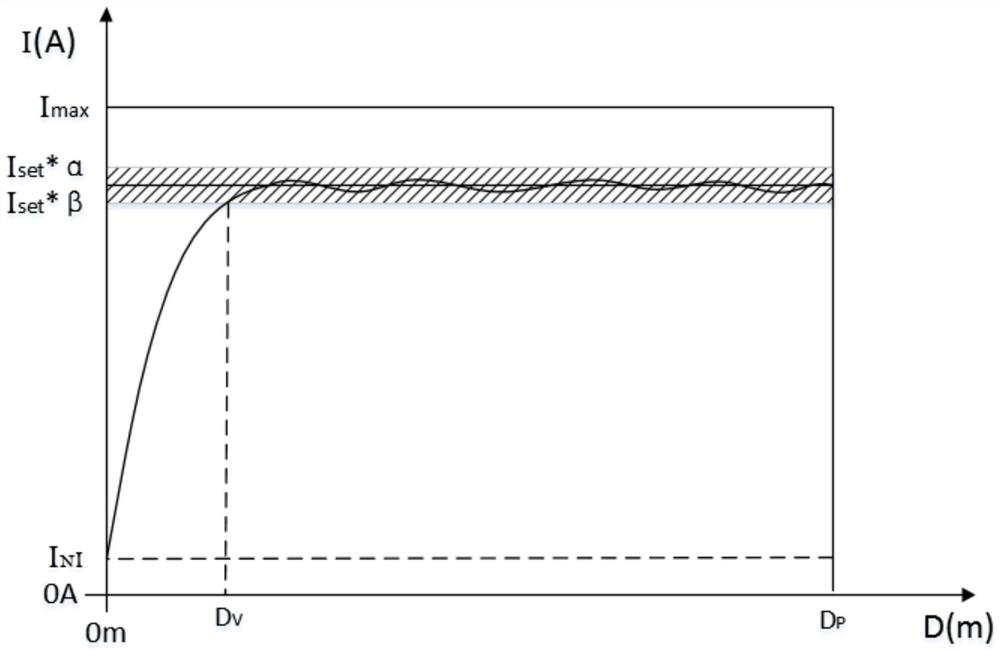

[0060] like Figure 1 to Figure 4 As shown, the ordinate represents the vibration current I, the unit A, and the abscissa represents the vibration depth D, the unit m.

[0061] I max It is the maximum working current of the vibrator. This current value is determined by the equipment. Exceeding this current may cause damage to the equipment and cause construction accidents.

[0062] I set In order to set the current, it is also called the vibration retention current. This current v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com