Process pipe column

A technology of process pipe string and pipe string, which is applied in the field of petroleum exploration, can solve the problems of low sand control efficiency, achieve good sand control effect, long sand control validity period, and improve seepage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

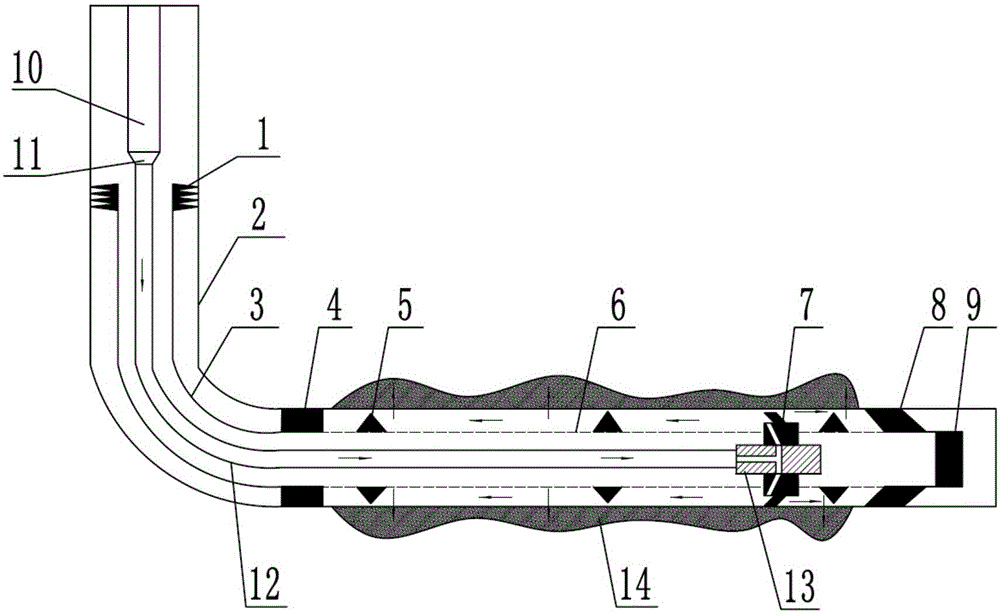

[0028] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

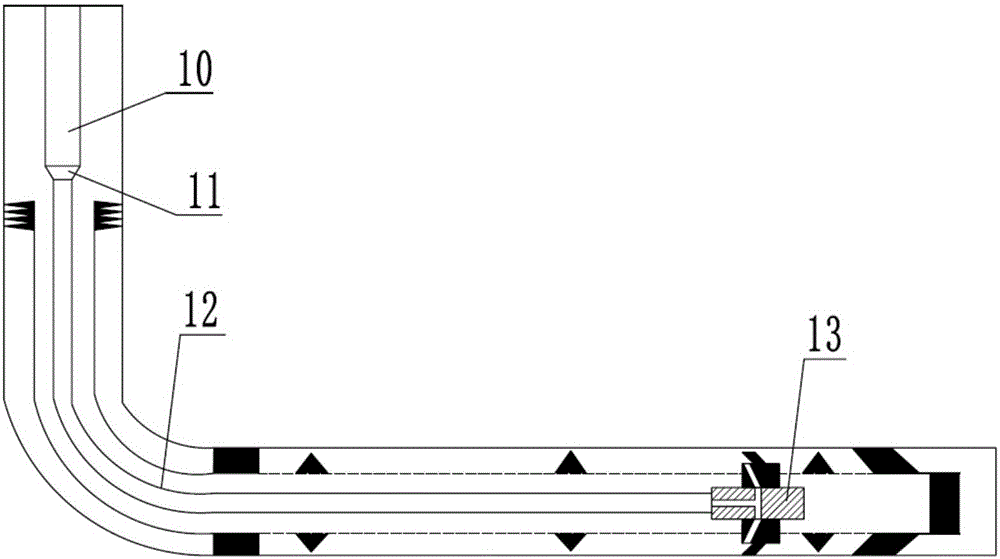

[0029] Attached below figure 1 ~ attached Image 6 The process column of the present invention will be further described with examples.

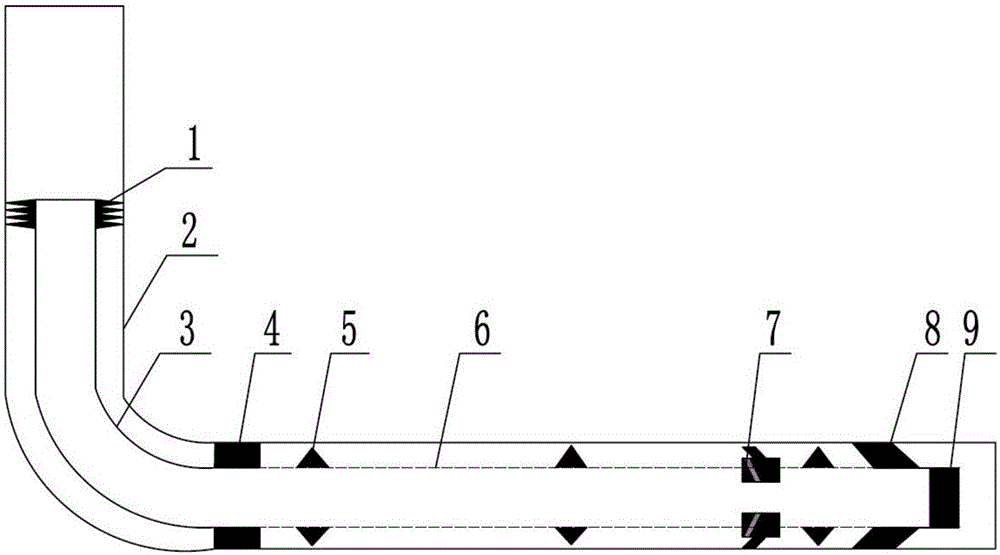

[0030] The invention mainly includes two sets of process pipe strings, a sand control pipe string and a filling service pipe string. Wherein, the sand control string is set in the casing 2, and there is a first gap between the sand control string and the casing 2; the filling service string is set in the sand control string, and there is a gap between the filling service string and the sand control string. second gap.

[0031] attached figure 1 It is a schematic diagram of the sand control pipe string of the horizontal well pipe extrusion gravel pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com