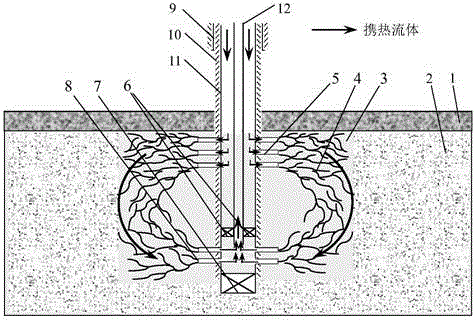

Single-well fracture gravity self-circulation dry-hot-rock geotherm mining method

A dry-hot rock, self-circulation technology, applied in the fields of fluid extraction, geothermal power generation, earthwork drilling, etc., can solve the problem of difficulty in constructing artificial fracturing reservoirs with high seepage capacity, etc., so as to improve heat recovery capacity and seepage flow. capacity, the effect of reducing the cost of drilling and completion of dual wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

[0034] A single well fracturing gravity self-circulation mining hot dry rock geothermal method, the specific steps are as follows:

[0035] (1) Select a medium-high temperature hot dry rock reservoir 2, use conventional drilling equipment, select a drill bit with a diameter greater than 60 cm, drill through the surface layer of the hot dry rock reservoir, lift the drill, and lower it into the surface casing 9, while using cement slurry cementing;

[0036](2) Install the wellhead and ground blowout prevention equipment, and then replace the drill bit with a diameter greater than 30cm for second opening. After encountering the cap rock 1, continue drilling until the hot dry rock reservoir is drilled, and drill to the area 10-30m away from the bottom of the hot dry rock reservoir;

[0037] (3) After lifting the drill hole, run the thermally conductive production casing 11 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com