High temperature seepage test device and method

An experimental device and seepage technology, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as inability to correctly reflect the formation permeability of coal and rock samples, and achieve simple structure and simple method. , the effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

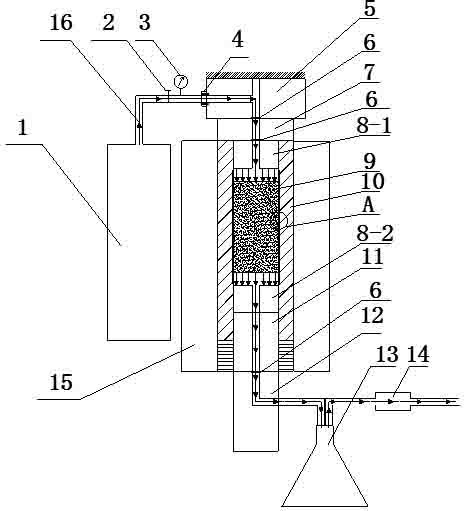

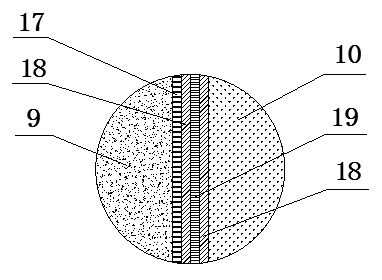

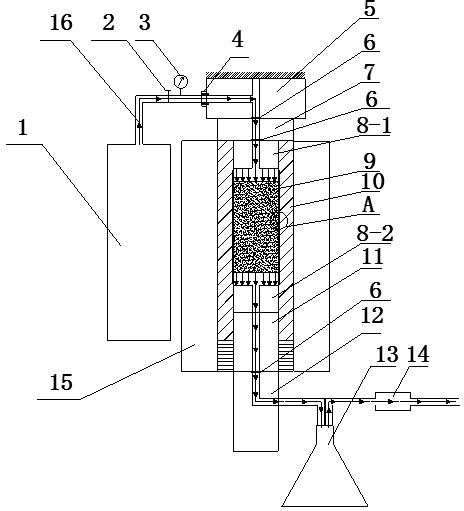

[0022] As shown in the accompanying drawings, the high-temperature seepage test device of the present invention mainly consists of a nitrogen cylinder 1, a pressure chamber 15, a pressure chamber cover plate 7 with a central hole, an upper and lower guiding pressure head, a main engine shaft pressure head 12, a collection bottle 13, The gas flow meter 14 is composed of the pressure chamber 15 using the double-layer shrink sleeve structure of the inner and outer H13 steel thick-walled cylinder cylinders. In the cavity of the pressure chamber 15, the surrounding pressure sleeve, the axial pressure head 11, and the guide air pressure are placed sequentially from bottom to top. Head 8, coal rock sample 9, upper and lower guide pressure heads, and coal rock sample 9 is wrapped tightly with red copper skin 17, mica paper 18, alloy resistance sheet 19, mica pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com