Strong draining and seepage-based upstream type tailings pond fill dam and damming technology thereof

A tailings pond, upstream technology, applied in filling and other directions, can solve problems such as difficulty in ensuring rapid tailings, sufficient drainage, immature research on unsaturated soils, and increased investment in grading station infrastructure. Low operating and construction costs, and the effect of preventing exposed slopes and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

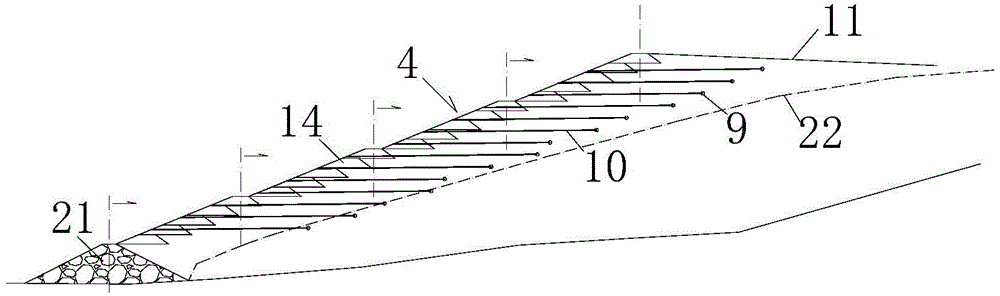

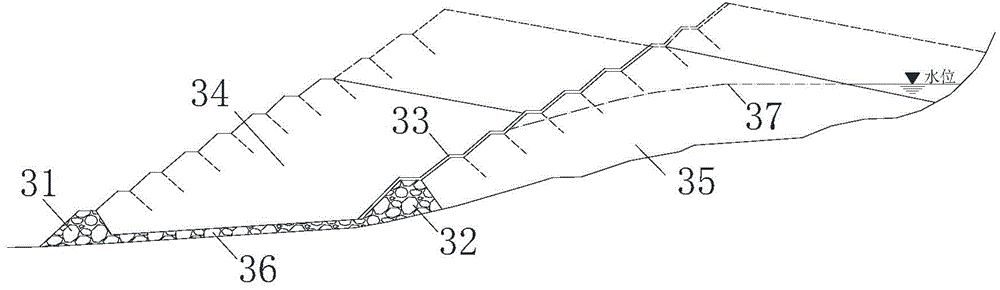

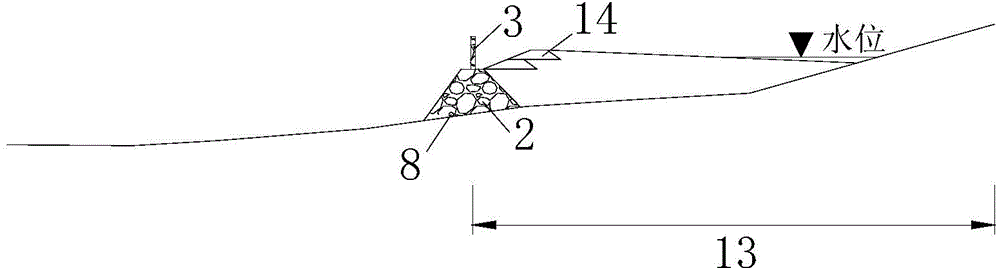

[0045] A certain tailings pond adopts the tailings pond accumulation dam based on the strong seepage upstream type of the present invention, such as Figure 7 As shown, the accumulation dam of the tailings pond is built on the basis of the two-stage dam structure of the tailings pond by the upstream dam-building method. The two-stage dam structure of the tailings pond includes the initial dam 1 arranged downstream of the tailings pond and the seepage dam 2 arranged upstream of the initial dam 1, the upstream reservoir area of the seepage dam 2 is the upper reservoir 13 for mainly stockpiling fine-grained tailings, and the reservoir area between the initial dam 1 and the seepage dam 2 is the main storage area The lower reservoir 12 for storing coarse tailings; the lower reservoir 12 utilizes hydraulic grading in the hydraulic alluvial process to first deposit coarse tailings in the lower reservoir, and then accumulate coarse tailings layer by layer to form a support body for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com