Experimental evaluation method of water trap damage of dense oil reservoir

An evaluation method and technology of reservoir water, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of inaccurate liquid flow measurement, overestimation of evaluation results, and limited evaluation range, and achieve elimination of channel effects. , Improve the seepage capacity, take care of the effect of the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below according to the accompanying drawings and specific experimental evaluation examples.

[0060] A core of a typical tight sandstone oil layer in the Ordos Basin is selected, and the present invention is used to carry out an experimental evaluation of the water phase trap damage of the tight oil layer. The detailed steps are as follows:

[0061] Step 1. Prepare shale cores according to the SYT5358-2010 rock sample preparation method; first, use nitrogen to drill and cut a core (S54-6) with a diameter of 2.46 cm and a length of 4.28 cm, and dry it at 63 °C to constant weight; The helium porosity of the core under 3MPa confining pressure is 15.3%, and the measured nitrogen permeability is 0.667mD according to Yee's law; the air tightness of the testing device is 48 hours, and the air tightness of the device meets the experimental requirements;

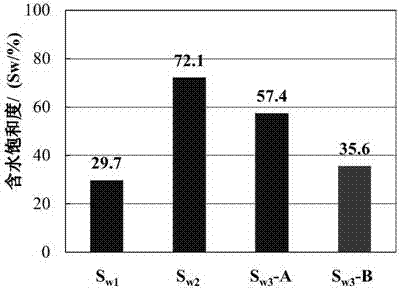

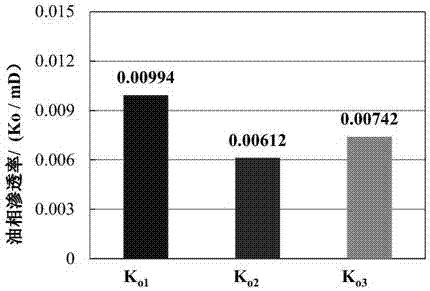

[0062] Step 2. After the core is saturated with simulated formation water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com