Sectionally constructed seepage drainage pipe for tailings dam

A technology for seepage drainage pipes and tailings dams is applied in the field of tailings dam seepage drainage pipes and construction methods for segmented construction, which can solve problems such as ineffective seepage drainage effects, reduce construction times and construction quantities, and enhance Drainage effect, effect of increasing effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

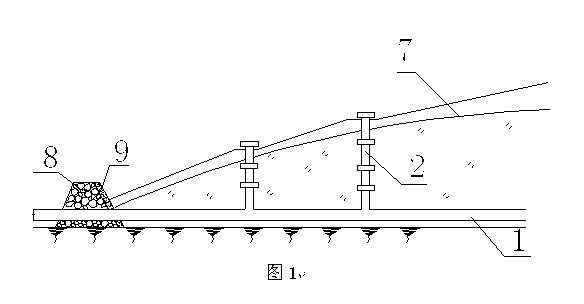

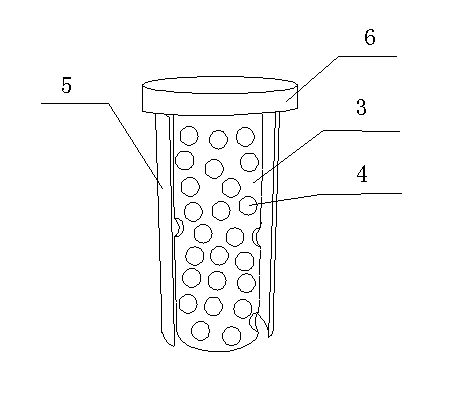

[0016] figure 1 It is a schematic diagram of a tailings dam drainage pipe and a tailings dam constructed in sections, in which a soaking line 7, an initial stage dam 8, and a reverse filter layer 9 are arranged, and the pre-buried seepage drainage pipe of the present invention consists of an aqueduct 1, The seepage pipe 2 is composed of the water guide pipe 1 and the seepage pipe 2. The escape point in the project generally appears at 1 / 3 to 1 / 2 from the dam crest, so the seepage pipe is installed at 1 / 3 from the dam crest. to 1 / 2, and lay the aqueduct at the bottom of the dam. Described aqueduct 1 can be the circular tube of rigid seat, and medium and small pipe diameter can be prefabricated, and seat is bigger during soil foundation. The aqueduct 1 is pre-buried horizontally at the bottom of the dam body, the seepage drainage pipe 2 is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com