Coal mine down-hole drilling penetration improvement method based on controllable shock wave technology

A shock wave and technology technology, applied in the field of energy and coal mine safety, can solve the problems of scrapped drilling, short duration of pre-pumping effect, and shock rock pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the drawings and specific embodiments:

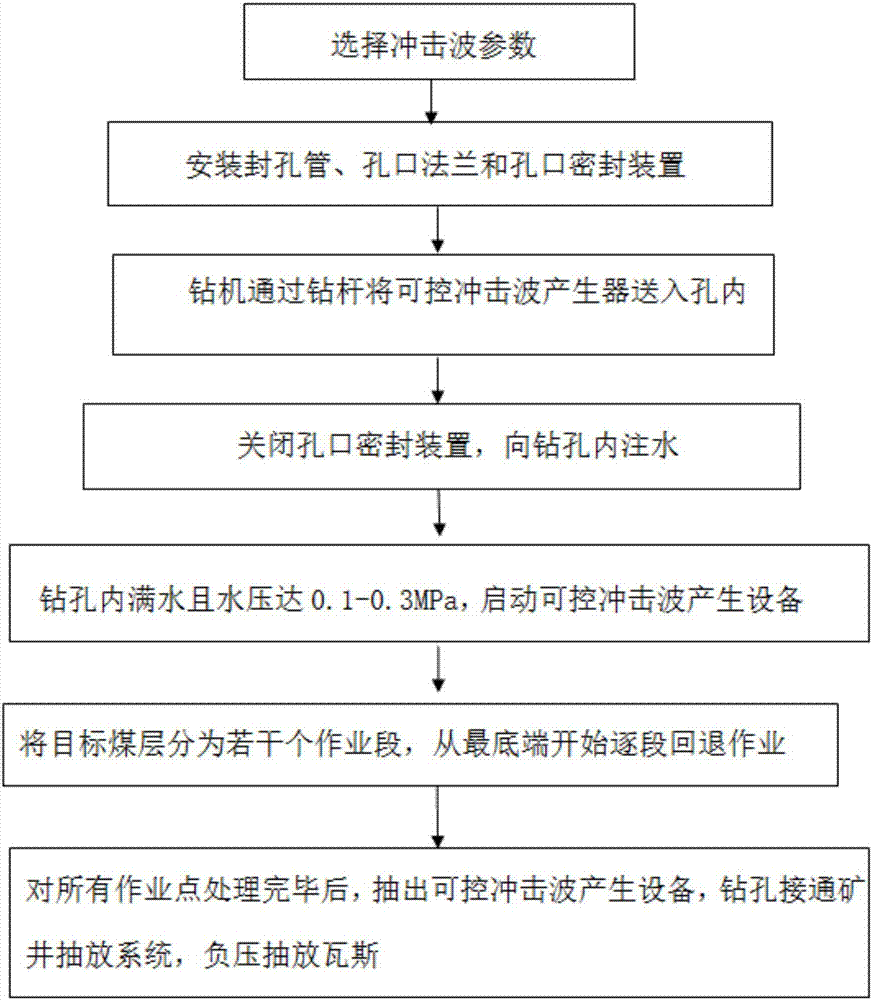

[0042] See figure 1 , The method for anti-reflection of coal mine boreholes based on controllable shock wave technology includes the following steps:

[0043] 1) A glass fiber reinforced plastic screen is sleeved in the borehole to form a supporting hole wall in the borehole to prevent the borehole from collapsing.

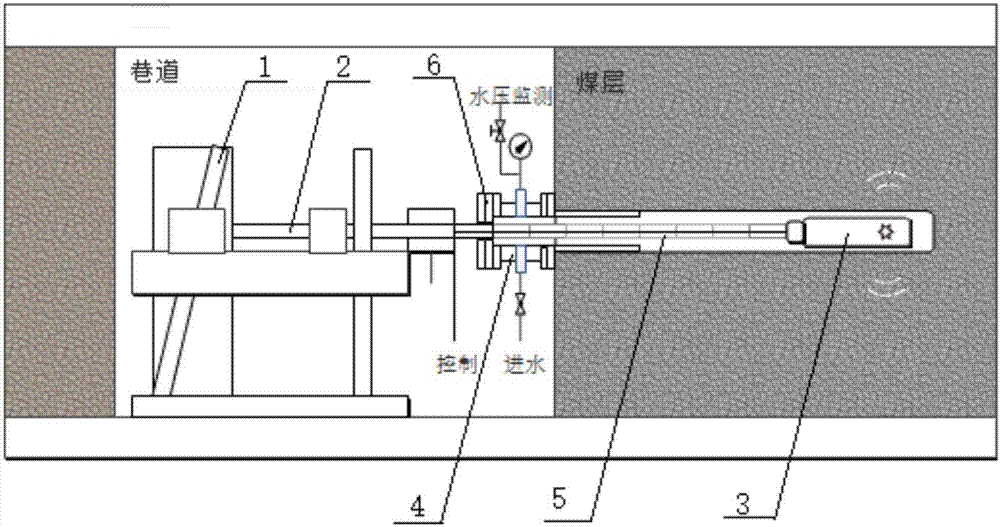

[0044] 2) Install the sealing pipe 5, the orifice flange 6 and the orifice sealing device 4;

[0045] 3) Rinse the borehole with large displacement of clean water to clean the cinder and large particles of impurities in the hole;

[0046] 4) The drilling rig 1 sends the controllable shock wave generator 3 into the borehole through the drill rod 2;

[0047] 5) Close the orifice sealing device 4, and pour water into the borehole;

[0048] 6) When the borehole is filled with water and the water pressure reaches 0.1-0.3MPa, the controller of the controllable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com