Boiling chlorination furnace with temperature-controlling device and temperature-controlling method thereof

A technology of fluidized chlorination furnace and temperature control device, which is applied in the direction of fluidized bed furnace, furnace, titanium halide, etc., can solve the problems such as difficult temperature control, and achieve the effects of low cost, improved accuracy and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

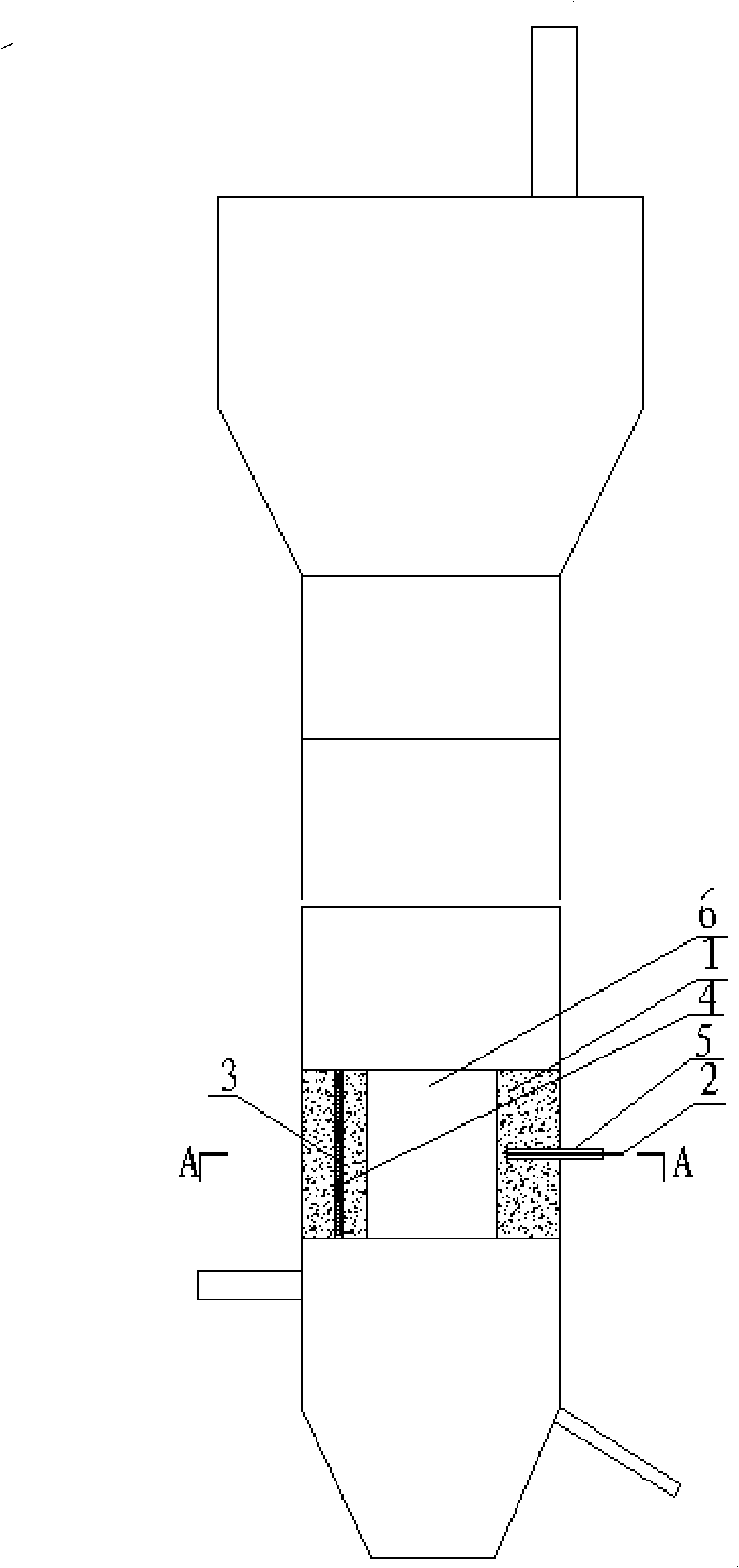

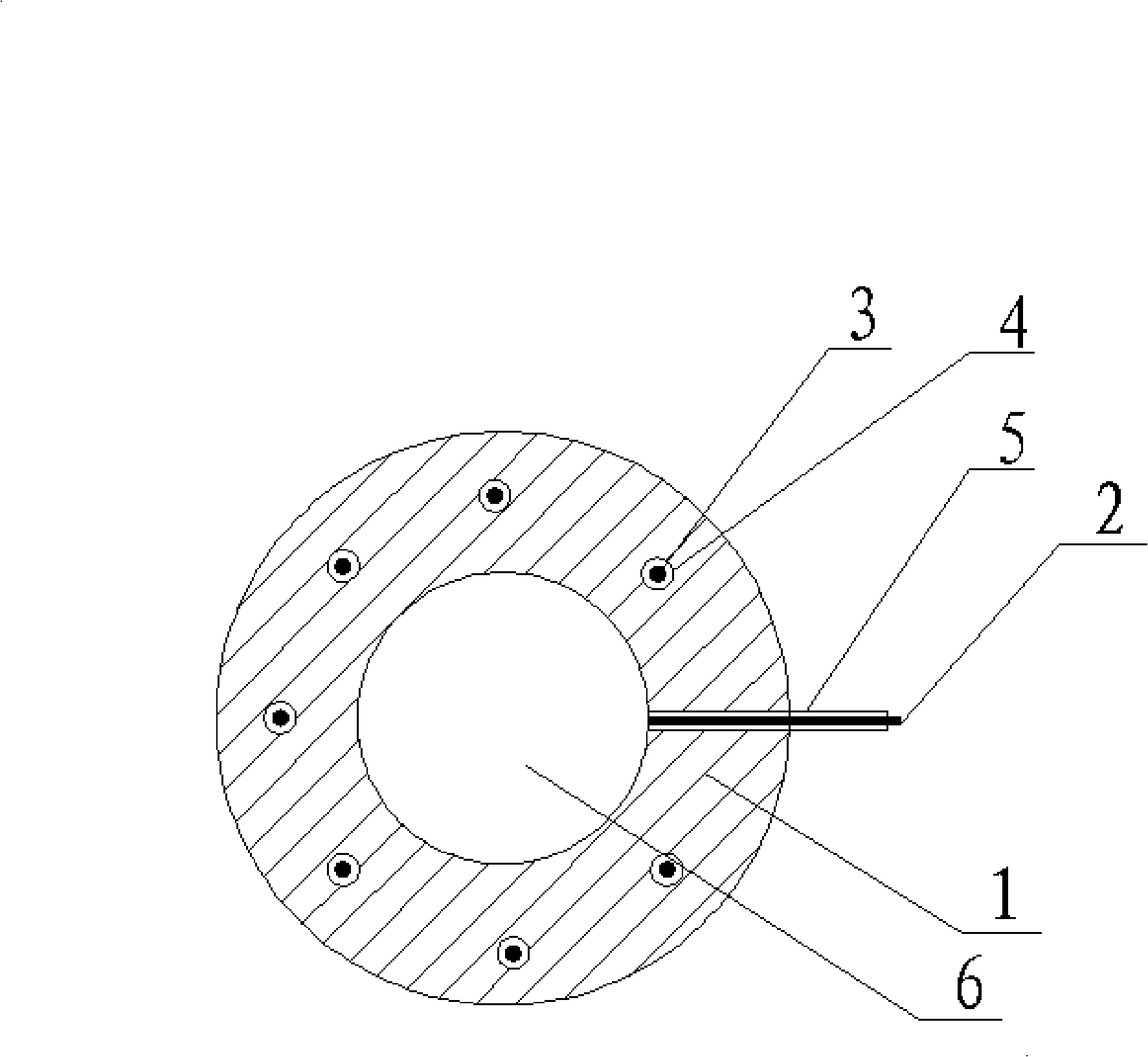

[0026] Apply the boiling chlorination furnace with temperature control device of the present invention and use high titanium slag as raw material to carry out boiling chlorination.

[0027] When the furnace is started, the chlorination furnace is heated by the heating resistance wire 3. When the temperature measured by the thermocouple 2 reaches 1000° C., high titanium slag and coke are added in a ratio of 3:1, and the reaction starts. At this time, the heating of the resistance wire 3 can be stopped, or the heating power can be reduced. When the heat in the furnace decreases sharply due to unstable feeding or slag discharge, restart the heating of the resistance wire 3 to maintain the balance of heat in the furnace and the stability of the temperature. , to ensure the smooth operation of the chlorination furnace.

Embodiment 2

[0029] Apply the boiling chlorination furnace with temperature control device of the present invention and use titanium carbide as raw material to carry out boiling chlorination.

[0030] When the furnace is started, the chlorination furnace is heated by the heating resistance wire 3, and when the temperature measured by the thermocouple 2 reaches 500°C, titanium carbide is added and chlorine gas is passed through, and the reaction begins. At this time, the heating of the resistance wire 3 can be stopped, or the heating power can be reduced. When the heat in the furnace decreases sharply due to unstable feeding or slag discharge, restart the heating of the resistance wire 3 to maintain the balance of heat in the furnace and the stability of the temperature. , to ensure the smooth operation of the chlorination furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com