Method for producing titanium tetrachloride in large-sized high temperature boiling chlorination furnace

A technology of high temperature boiling, titanium tetrachloride, applied in the direction of titanium halide and other directions, can solve problems such as difficulties, and achieve the effect of improving utilization rate, increasing production capacity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

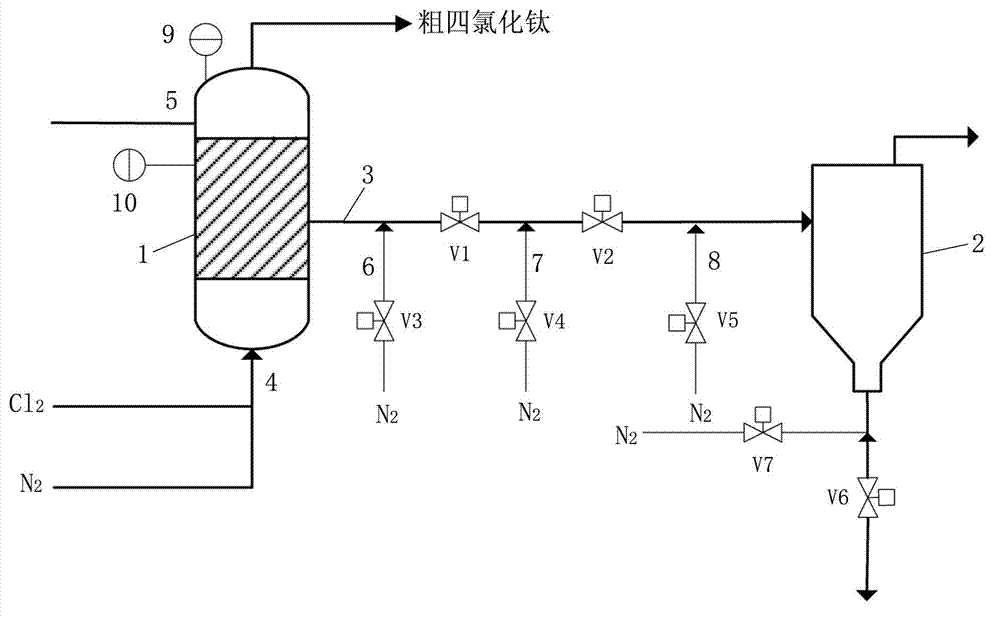

Image

Examples

example 1

[0039] The composition of the high titanium slag adopted in this example contains by weight percentage: TiO 2 85%, FeO9%, Al 2 o 3 2.0%, CaO0.15%, MgO1.0%, SiO 2 1.0%, and 95% of which have a high particle size between 0.15mm and 0.30mm. The diameter of the chlorination furnace used is 5500mm.

[0040] Mix 77 parts of high-titanium slag and 23 parts of petroleum coke evenly to form a mixture, and then use the FK pump to spray the mixture into the chlorination furnace from the feeding port at a speed of 25t / h. At the same time, from the bottom of the chlorination furnace The gas inlet is fed into gas at a speed of 50t / h, wherein chlorine accounts for 73wt%, nitrogen accounts for 27wt%, and the superficial gas velocity above the material layer is controlled between 0.5m / s~0.55m / s; During the chlorination reaction process of the material and chlorine gas, the pressure difference between the air pressure in the dilute phase section of the chlorination furnace and the atmospher...

example 2

[0043] The composition of the high titanium slag adopted in this example contains by weight percentage: TiO 2 88%, FeO8%, Al 2 o 3 1.0%, CaO0.13%, MgO0.5%, SiO 2 1.5%, and 90% of which have a high particle size between 0.15mm and 0.30mm. The diameter of the chlorination furnace used is 5500mm.

[0044] Mix 75 parts of high-titanium slag and 25 parts of petroleum coke evenly to form a mixture, and then use the FK pump to spray the mixture into the chlorination furnace from the feeding port at a speed of 20t / h. At the same time, from the bottom of the chlorination furnace The gas inlet is passed into the gas at a speed of 41t / h, wherein chlorine accounts for 72wt%, nitrogen accounts for 28wt%, and the superficial gas velocity above the material layer is controlled between 0.5m / s~0.55m / s; During the chlorination reaction process of the material and chlorine gas, the pressure difference between the air pressure in the dilute phase section of the chlorination furnace and the at...

example 3

[0047] The composition of the high titanium slag adopted in this example contains by weight percentage: TiO 2 86%, FeO8.5%, Al 2 o 3 1.5%, CaO0.10%, MgO0.75%, SiO 2 2.0%, and 93% of which have a high particle size between 0.15mm and 0.30mm. The diameter of the chlorination furnace used is 5500mm.

[0048] Mix 80 parts of high-titanium slag and 20 parts of petroleum coke evenly to form a mixture, and then use the FK pump to spray the mixture into the chlorination furnace from the feeding port at a speed of 23t / h. At the same time, from the bottom of the chlorination furnace The gas inlet is fed into gas at a speed of 45t / h, wherein chlorine accounts for 80wt%, nitrogen accounts for 20wt%, and the superficial gas velocity above the material layer is controlled between 0.5m / s~0.55m / s; During the chlorination reaction process of the material and chlorine, the pressure difference between the air pressure in the dilute phase section of the chlorination furnace and the atmospheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com