Operation method and device for continuous refining of titanium tetrachloride crude

An operation method, the technology of titanium tetrachloride, applied in the direction of titanium halide, etc., can solve the problems of high labor intensity, high energy consumption, unstable product quality, etc., and achieve the effect of improving product quality and increasing throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The raw material composition of titanium tetrachloride crude product is as follows: TiCl 4 ≥99.9; VOCl 3 ≤0.06; FeCl 3 ≤0.003; SiCl 4 ≤0.02, other heavy components ≤0.007%, liquid-solid ratio<0.5%.

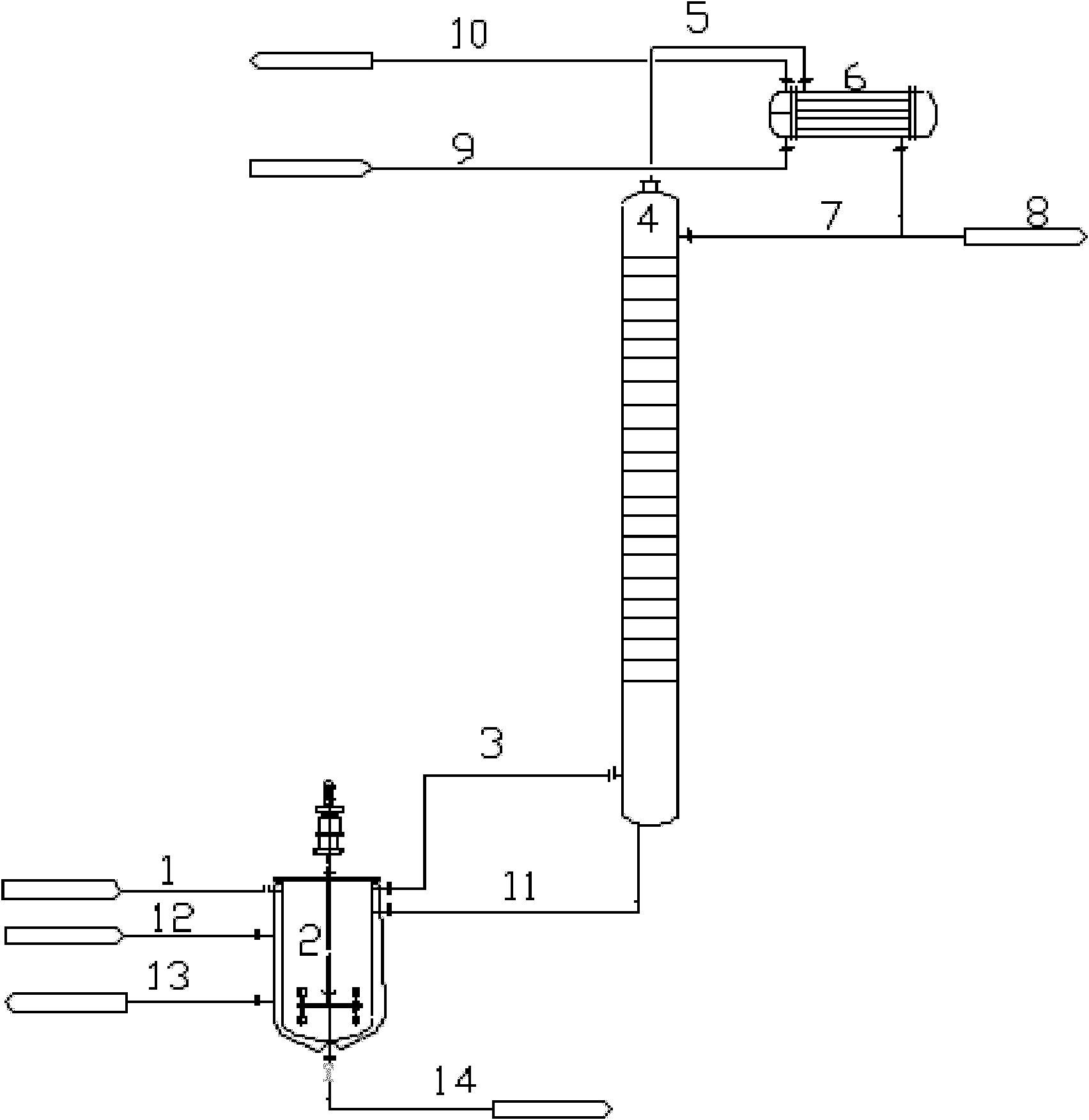

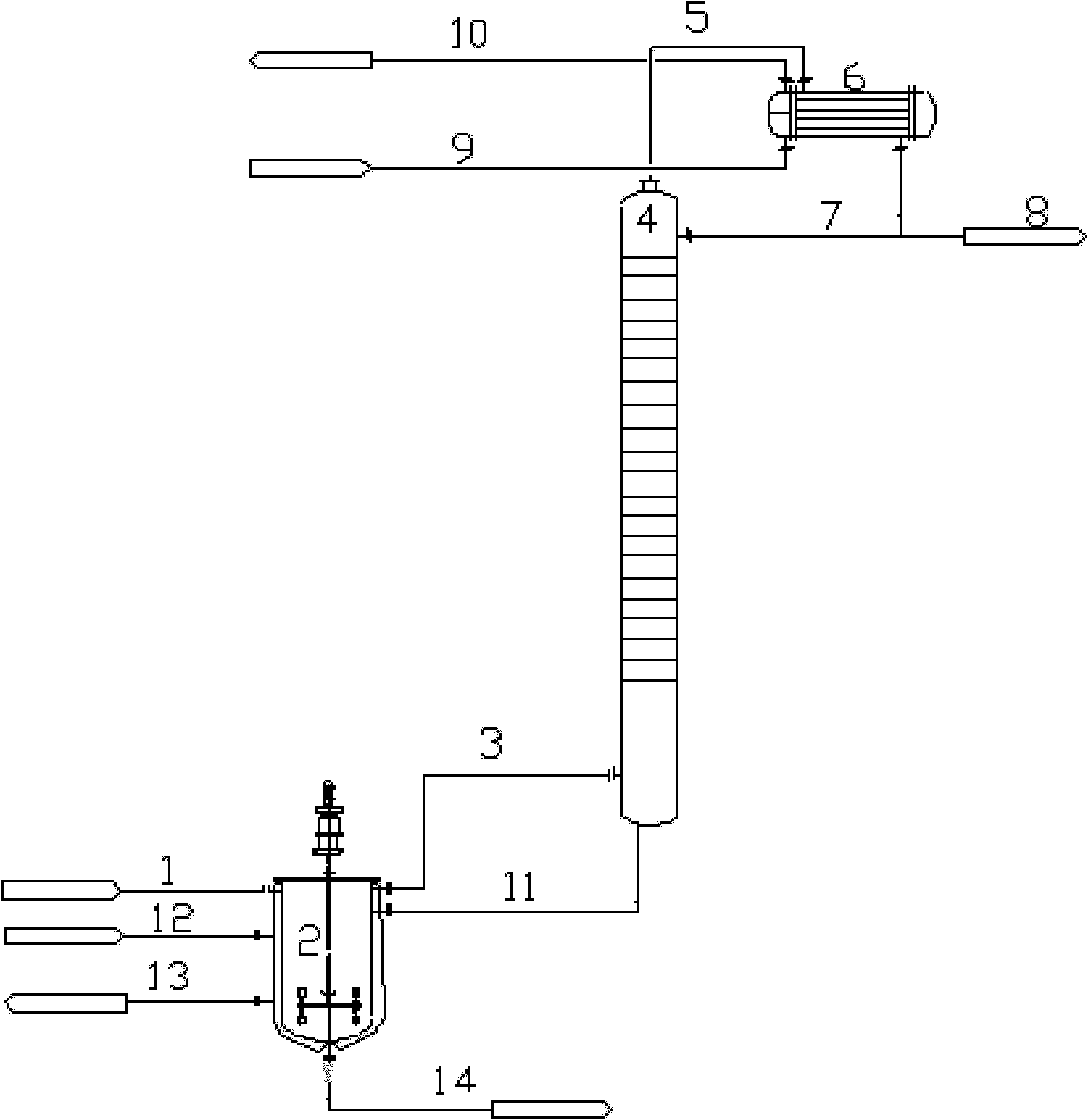

[0017] Crude titanium tetrachloride 1 continuously enters the evaporating kettle 2 with stirring, and is fed into the heat conduction oil 12 of the system, so that the temperature in the evaporating kettle is controlled at 145°C, the stirring motor rotates at 10 rpm, and the crude titanium tetrachloride 1 Evaporation is carried out in the agitated evaporation tank 2, and the generated steam 3 enters the rectification column system 4. The steam 5 at the top of the rectification column is condensed into a liquid phase by the cooling medium water 9 entering the system in the condenser 6, and the temperature of the condensed liquid phase is 40°C. A part of the liquid phase is extracted as a refined titanium tetrachloride product 8 and leaves the system , the other part retu...

Embodiment 2

[0019] All the other conditions were the same as in Example 1, and the temperature in the stirring evaporator 2 was controlled at 150°C.

Embodiment 3

[0021] The rest of the conditions are the same as in Example 1, and the temperature in the stirring evaporator 2 is controlled at 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com