Device of boiling chlorination furnace for continuous slagging and slagging method

A technology of boiling chlorination furnace and slag, applied in the direction of titanium halide, etc., can solve the problems of lack of sealing, controllable and continuous slag discharge technology of chlorination furnace, difficulty in realizing slag discharge rate control, and inability to discharge large particle slag, etc. Achieve the effect of improving reliability and operability, easy automatic control, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

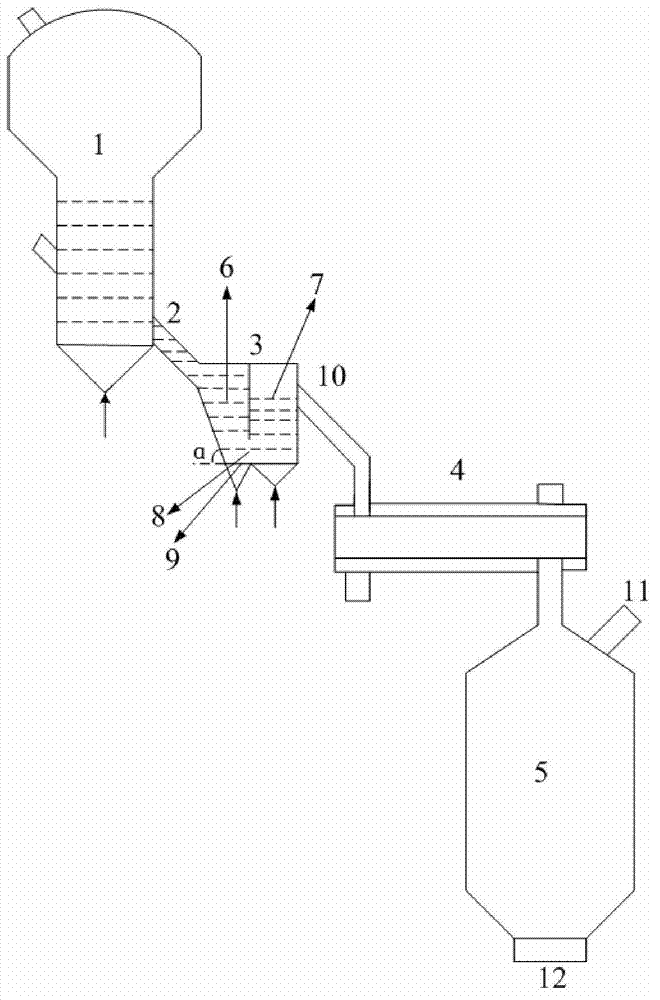

[0035] like figure 1 As shown, a continuous slagging device for a fluidized chlorination furnace, the device is composed of a slagging pipe 2, a slagging valve 3, a water-cooled screw slagging machine 4 and a slag tank 5 connected in sequence; the slagging pipe 2 Connect the bottom slag outlet of fluidized chlorination furnace 1. The slag discharge valve 3 includes a standpipe 6 and a discharge chamber 7 arranged side by side; the discharge chamber 7 communicates with the standpipe 6 through an orifice 8 at the bottom, and a discharge port 10 is provided on its upper part; One side of the pipe 6 is a slope; the bottom of the standpipe 6 and the discharge chamber 7 are respectively provided with air inlets, and a gas distribution plate 9 is arranged above the air inlets. The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com