A kind of production method of waste plastics continuous oiling by utilizing waste plastics continuous oiling device

A production method and technology of waste plastics, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of inability to carry out continuous production, waste of energy, and inability to discharge slag at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

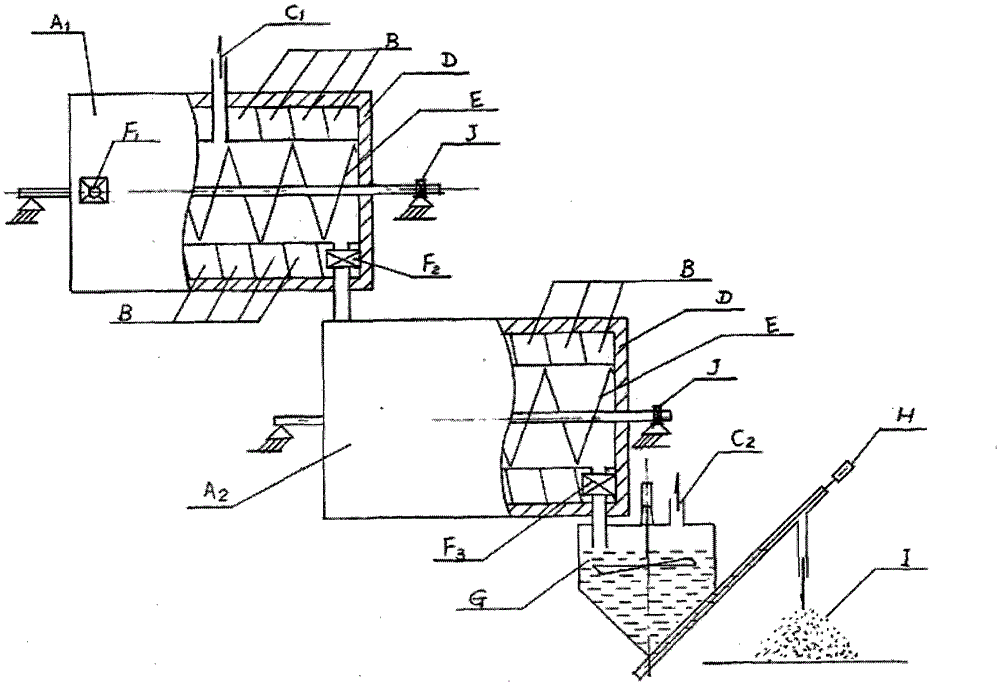

[0019] Such as figure 1 As shown, a continuous carburetion device for waste plastics includes a cracking reactor A1 and a slagging buffer tank A2, the feed port of the cracking reactor A1 is provided with a first hydraulic sealing valve F1, and the slagging of the cracking reactor The second hydraulic sealing valve F2 is set at the port, and the slag outlet of the cracking reactor is connected with the slagging buffer tank through a pipeline, the gas outlet C1 is arranged above the cracking reactor, and the outer wall of the cracking reactor and the slagging buffer tank is set An annular heating air channel B, the outer periphery of the annular heating air channel is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com