A settling tank for continuous separation of solid content of wet-process phosphoric acid

A technology of wet-process phosphoric acid and settling tank, which is applied in the direction of settling tank, separation method, feeding/discharging device of settling tank, etc. It can solve the problems of mud scraper locking, affecting production efficiency, easy blockage, etc., and achieves production The effect of improving efficiency and product quality, ensuring continuous and stable operation, and accelerating the speed of acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

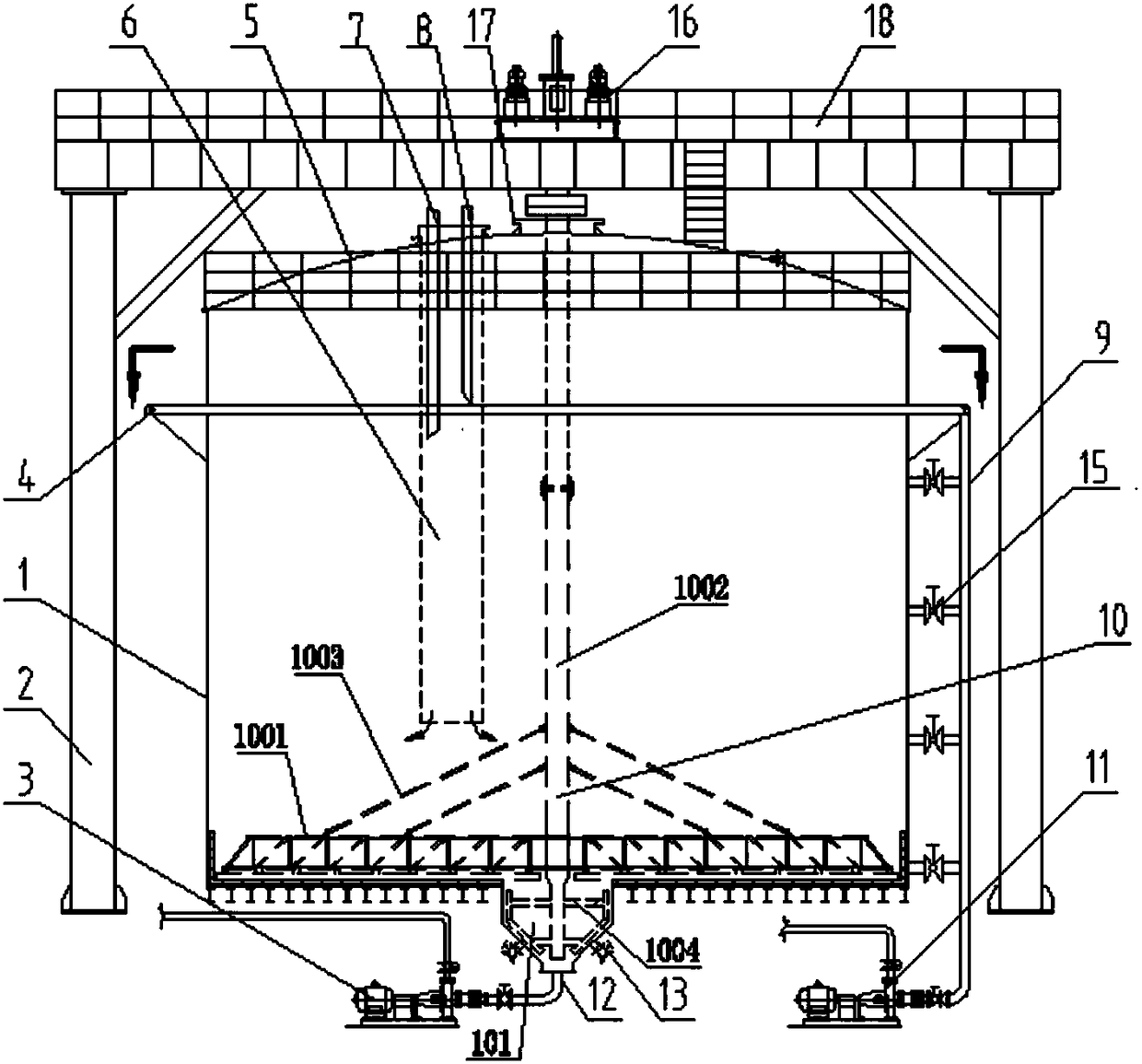

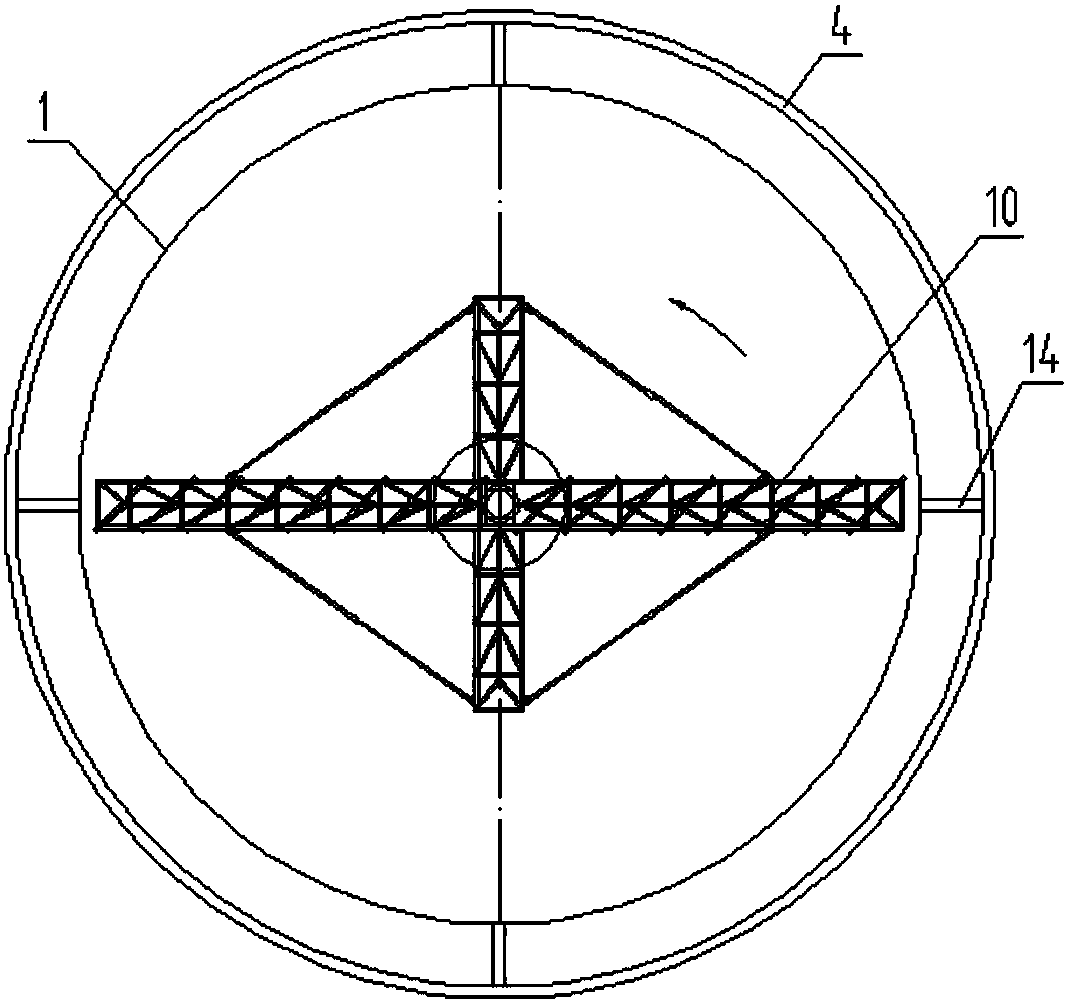

[0037] When the device is working, dilute phosphoric acid or concentrated phosphoric acid from the phosphoric acid workshop enters the acid inlet tube 6 through the acid inlet tube 7 installed on the acid inlet guide tube 6, and the solid content in the lower part of the settling tank body 1 is settled by gravity. The effect is higher than that of the upper part. At the same time, the flocculant polyacrylamide is added from the phosphoric acid purification flocculant addition pipe 8, and the added phosphoric acid is fully charged in the acid inlet guide tube 6 by the height difference between the acid inlet pipe 7 and the phosphoric acid purification flocculant addition pipe 8. Mixing, the mixed acid enters the settling tank body 1 through the acid inlet guide tube 6 for gravity settling. The acid inlet guide tube 6 is 316L stainless steel, and the part exposed to the acid liquid surface in the acid inlet guide tube 6 should be lined with rubber to prevent fluorine corrosion. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com