Use and maintenance method of micro-foam drilling fluid

A technology of drilling fluid and foam, which is applied in the field of use and maintenance of micro-foam drilling fluid, and can solve problems such as increased maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

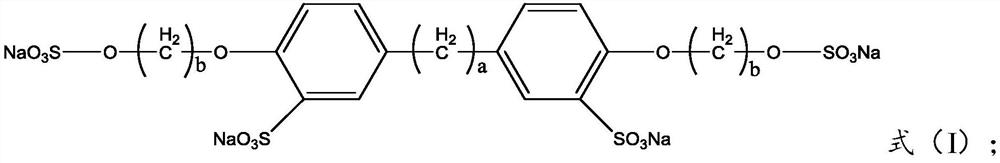

[0062] 1.1 At first the dichloromethane solution (purity >99%) of 45mL, the potassium hydroxide (purity >99%) of 12.5 parts by weight, the cetrimonium bromide (purity >99%) of 1.5 parts by weight are packed with In the three-neck flask of the tail gas absorption device and the reflux condenser. After heating to 30°C, add 17.5 parts by weight of bisphenol F (purity>99%), continue heating to 50°C, add 68.5 parts by weight of 4-bromo-1-butanol (purity>99%) ), and keep stirring continuously to make the reaction complete. After the reaction is completed, the system is cooled, and the reaction product is filtered and purified to obtain a diether alcohol intermediate. The reaction process is as follows.

[0063]

[0064] Under the condition of stirring, add the diether alcohol intermediate into a three-neck flask (equipped with HCl treatment device) containing 45mL of dichloromethane solution (purity >99%), and slowly add it dropwise to the system at 10°C 10.5 parts by weight of...

Embodiment 2

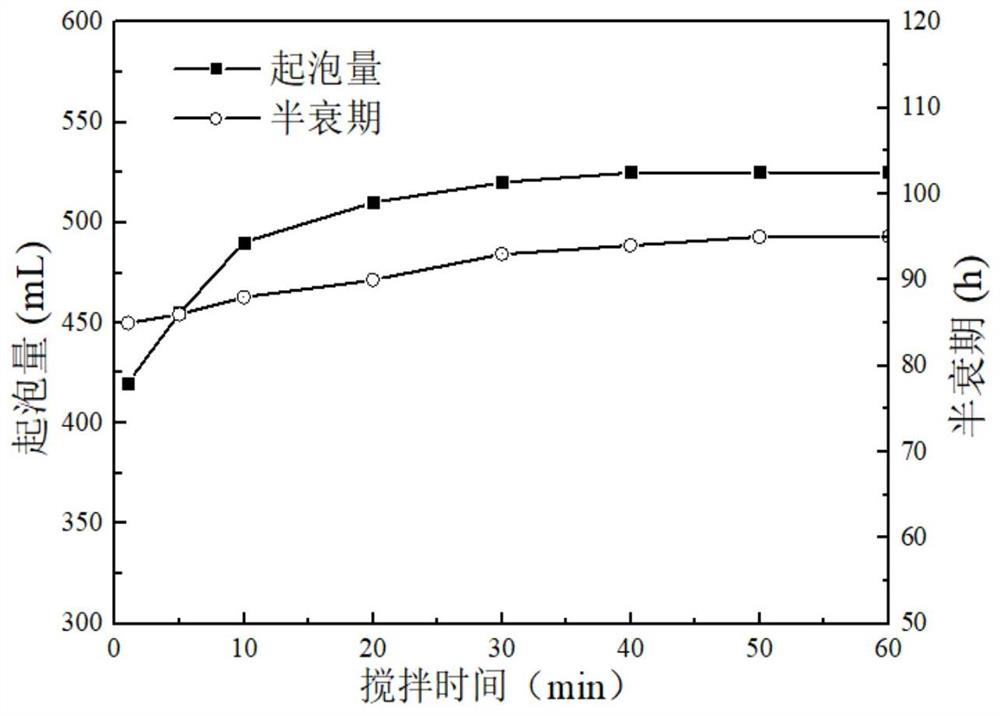

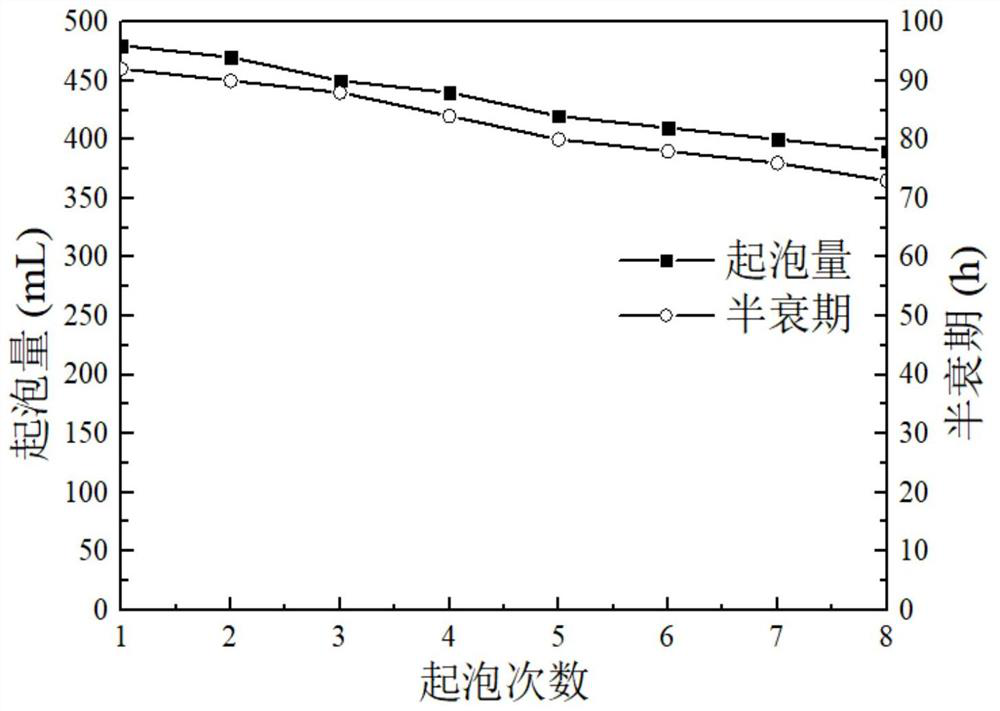

[0067] ① Weigh a certain amount of foam stabilizer and inhibitor into a mixing cup filled with 200mL of water, and add while stirring to ensure that the polymer is completely dispersed and dissolved. Then gradually add a certain quality of foaming agent into the mixing cup, and at the same time stir with a glass rod to ensure that the foaming agent is fully dissolved. Fix the stirring cup on the high-speed blender, and stir for 1 min at a speed of 11000r / min±300r / min; ②After the stirring is completed, immediately remove the stirring cup, pour all the foam fluid in it into a 1000mL measuring cylinder, and record the Start the stopwatch at the same time to record the defoaming time; ③Repeat step ①, pour an appropriate amount of the foam system into the mud cup to test the rheology of the multi-stage foam system, including Initial and final cut; ④ Pour an appropriate amount of foam fluid into the mud tank of the water loss meter and hang the tank on the multi-connected water los...

Embodiment 3

[0112] In field use and maintenance, with system formula: 0.1% ULIT-1 (embodiment 1)+0.2% lauryl dimethyl betaine+0.3% biopolymer XC+0.2% guar gum GHPG+1% lignite resin + 1% ammonium salt + 0.2% potassium polyacrylate as the benchmark, select a microfoam drilling fluid system with a stirring condition of 5000r / min for 30min, and a stirring base fluid volume of 300mL, and measure its plugging performance. The results are shown in Table 11. The analysis data shows that microfoam can effectively block the pore space formed by quartz sand with different meshes, and the plugging effect is good.

[0113] Table 11 Plugging test of multi-stage foam low-damage drilling fluid system on different meshes of quartz sand under different pressures

[0114]

[0115] Note: 5000r / min, 300mL, 30min

[0116] (2) Evaluation of reservoir protection effect of microfoam drilling fluid system

[0117] Coal rock cores from representative coal seams were selected to evaluate the reservoir protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com