Method and device for recovering positive electrode material from lithium battery slurry

A positive electrode material and lithium battery technology, which is applied in the field of recycling positive electrode materials, can solve the problems of difficulty in entering the incinerator for barreled materials, high processing pressure, easy agglomeration of materials, sticking to the wall, etc., so as to reduce the burden of processing, reduce decomposition, reduce Effect of degree of pyrolytic agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

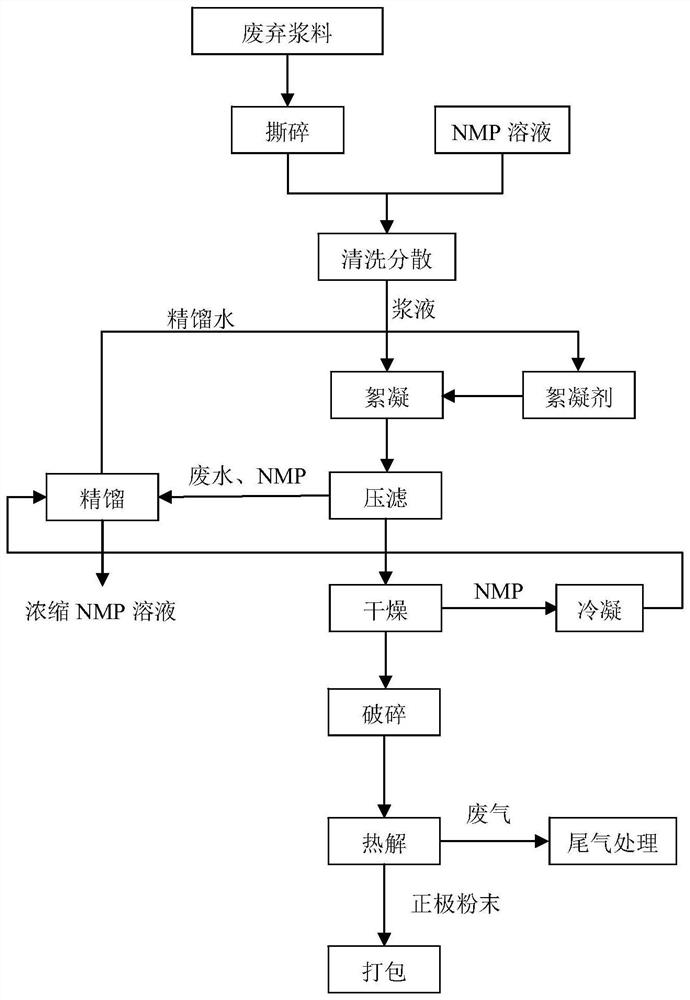

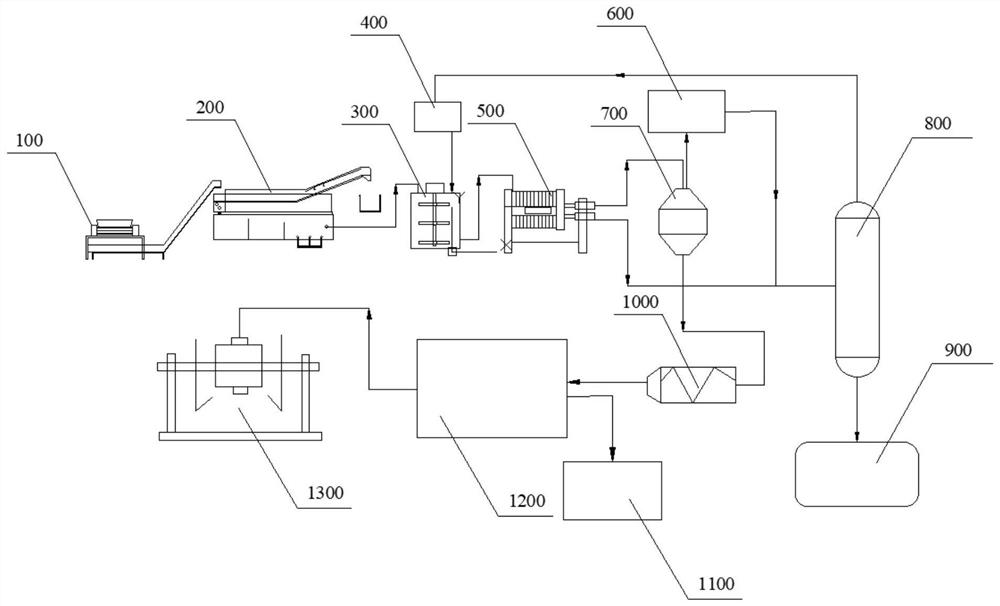

[0084] The method for recovering positive electrode material from lithium battery slurry comprises the following steps:

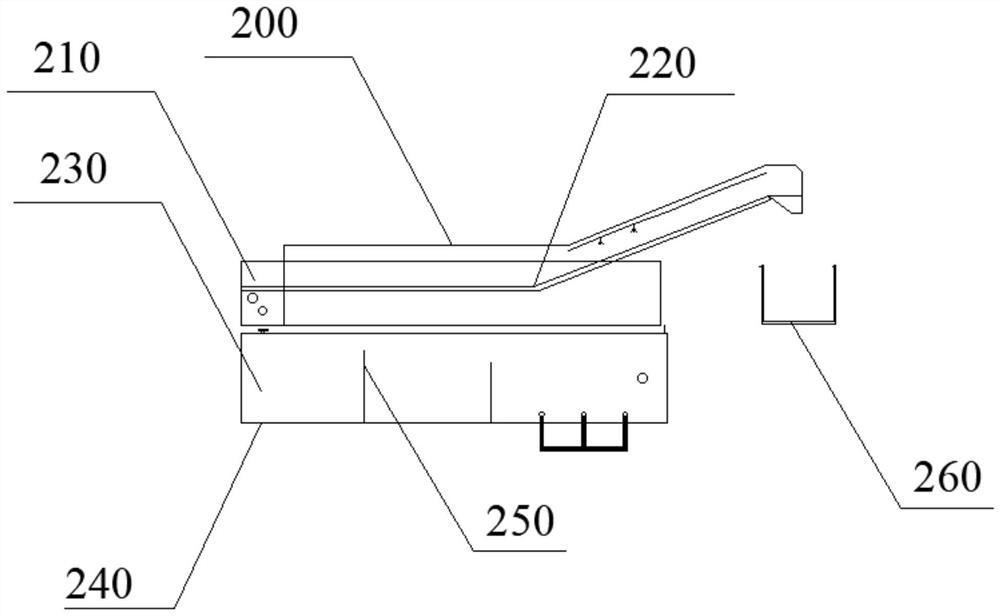

[0085] S1: Take 1000L of waste slurry containing foreign matter such as plastics and cloth strips and shred it in a double-shaft shredder. The A-axis crushing speed is 15r / min, and the B-axis crushing speed is 25r / min;

[0086] S2: The shredded waste slurry is mixed with 2000L of NMP solution with a concentration of 70% to 85%, and then the bubbles are broken, and the pressure of the bubble break is 0.4Mpa, so as to peel off the waste slurry adhered to the foreign matter from the foreign matter , and the waste slurry is broken, and then further broken through step by step overflow;

[0087] S3: Using ferric sulfate as flocculant, the volume ratio between slurry and flocculant is 1000:5 for dispersion stirring and flocculation, wherein the stirring speed is 20r / min, the dispersion speed is 1000r / min, and the dispersion time is 30min;

[0088] S4: Under the ...

Embodiment 2

[0094] The method for recovering positive electrode material from lithium battery slurry comprises the following steps:

[0095] S1: Take 2000L of waste slurry containing foreign matter such as plastics and cloth strips and shred it in a double-shaft shredder. The A-axis crushing speed is 25r / min, and the B-axis crushing speed is 15r / min;

[0096] S2: The shredded waste slurry is mixed with 1000L of NMP solution with a concentration of 70% to 90%, and then the bubbles are broken, and the pressure of the bubble break is 0.8Mpa, so as to peel off the waste slurry adhered to the foreign matter from the foreign matter , and crush the waste slurry, and then further crush the waste slurry into a slurry with a size and a solid content that meets the requirements through step-by-step overflow crushing;

[0097] S3: Using ferric sulfate as flocculant, the volume ratio between slurry and flocculant is 1000:20 for dispersion stirring and flocculation, wherein the stirring speed is 50r / mi...

Embodiment 3

[0104] The method for recovering positive electrode material from lithium battery slurry comprises the following steps:

[0105] S1: Take 1500L of waste slurry containing foreign matter such as plastics and cloth strips and shred it in a double-shaft shredder, the A-axis crushing speed is 20r / min, and the B-axis crushing speed is 20r / min;

[0106] S2: The shredded waste slurry is mixed with 1500L of NMP solution with a concentration of 70% to 85%, and then the bubbles are crushed. The pressure of the bubble crushing is 0.6Mpa, so as to remove the waste slurry adhering to the foreign matter from the foreign matter. , and crush the waste slurry, and then further crush the waste slurry into a slurry with a size and a solid content that meets the requirements through step-by-step overflow crushing;

[0107] S3: Using ferric sulfate as flocculant, the volume ratio between slurry and flocculant is 1000:10 for dispersion stirring and flocculation, wherein the stirring speed is 30r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com