Nano zero-valent iron-copper-carbon microsphere material and preparation method thereof

A nano-zero-valent iron, copper-carbon technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unsolved nano-iron agglomeration, low recovery rate, low catalytic activity of catalysts, etc. Better diameter, improved catalytic activity, and superior catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

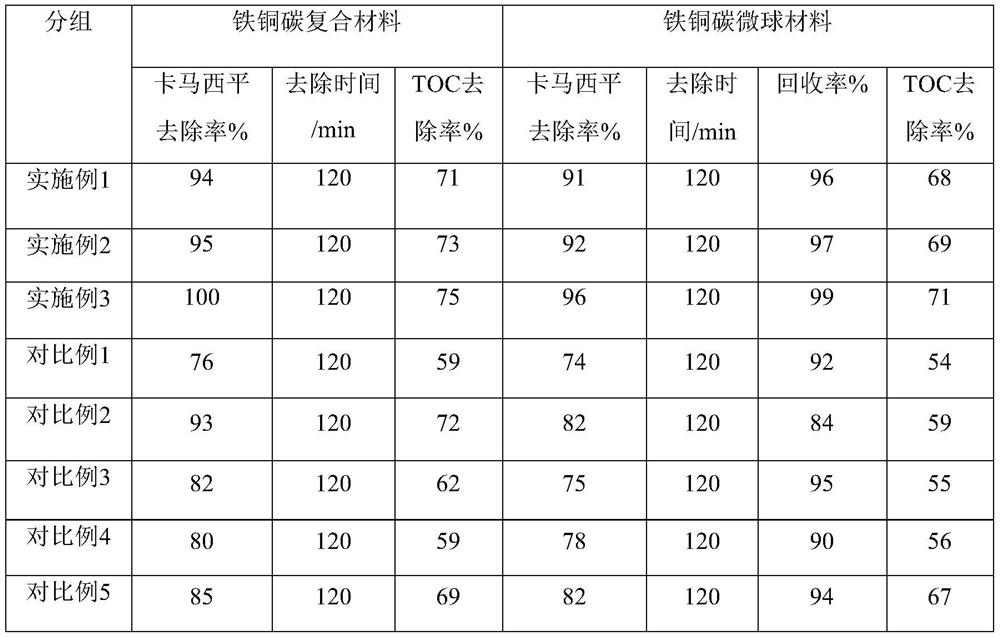

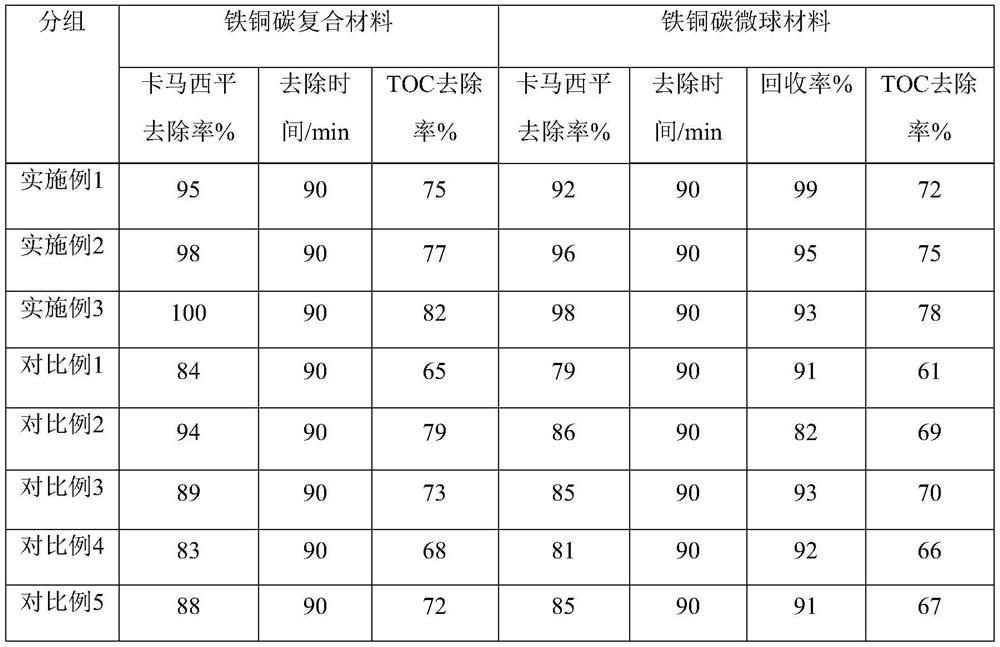

Examples

Embodiment 1

[0033] The raw material iron monomer of the iron-copper-carbon composite material is 3 parts of ferrous acetate, 1 part of carbon monomer, and 0.95 parts of basic copper carbonate as the copper monomer. The carbon monomer is a mixture of ethylenediaminetetraacetic acid, mannitol and β-cyclodextrin with a mass ratio of 1:0.5:0.2.

[0034] The preparation method of iron-copper-carbon composite material is as follows:

[0035] (1) Put the raw materials iron monomer, carbon monomer and copper monomer in a planetary ball mill, add 0.1% talc powder, then add 5 grinding balls of 5mm and 7mm each, set the speed at 300rpm / min, and grind for 3h , to obtain the mixture for later use;

[0036](2) Put the above mixture in a tube furnace, feed nitrogen to avoid explosion due to oxygen incorporation, set the nitrogen flow rate to 300mL / min, raise the temperature to 450°C at a rate of 6°C / min, keep it for 30min, and then increase the temperature at 10°C The heating rate was raised to 700°C ...

Embodiment 2

[0042] The raw material iron monomer of the iron-copper-carbon composite material is 3 parts of ferrous acetate, 1 part of carbon monomer, and 1.9 parts of basic copper carbonate as the copper monomer.

[0043] The carbon monomer is a mixture of ethylenediaminetetraacetic acid, mannitol and β-cyclodextrin with a mass ratio of 4:1:0.5.

[0044] The preparation method of iron-copper-carbon composite material is as follows:

[0045] (1) Put the raw material iron monomer, carbon monomer and copper monomer in a planetary ball mill, add 0.2% talcum powder, then add 5 grinding balls each of 5mm and 7mm, set the speed at 350rpm / min, and mechanically grind 2h, obtain the mixture for subsequent use;

[0046] (2) Put the above mixture in a tube furnace, feed nitrogen to avoid explosion caused by oxygen incorporation, set the nitrogen flow rate to 250mL / min, raise the temperature to 500°C at a rate of 8°C / min, keep it for 30min, and then increase the temperature at 10°C The heating rate...

Embodiment 3

[0052] The raw material iron monomer of the iron-copper-carbon composite material is 3 parts of ferrous acetate, 1 part of carbon monomer, and 3.8 parts of basic copper carbonate for copper monomer. The carbon monomer is a mixture of ethylenediaminetetraacetic acid, mannitol and β-cyclodextrin with a mass ratio of 2:1:0.3.

[0053] The preparation method of iron-copper-carbon composite material is as follows:

[0054] (1) Put the raw materials iron monomer, carbon monomer and copper monomer in a planetary ball mill, add 0.2% talc powder, then add 5 grinding balls of 5mm and 7mm each, set the speed at 300rpm / min, and grind for 4h , to obtain the mixture for later use;

[0055] (2) Put the above mixture in a tube furnace, feed nitrogen to avoid explosion due to oxygen incorporation, set the nitrogen flow rate to 350mL / min, raise the temperature to 500°C at a rate of 6°C / min, keep it for 50min, and then increase the temperature at 10°C The heating rate was increased to 800°C pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com