Method of inclusion body protein renaturation and purification at the same time

A protein renaturation and inclusion body technology, applied in the field of inclusion body protein renaturation and simultaneous purification, can solve problems such as being unsuitable for industrial production, unsuitable for large-scale production, increasing operation steps and operation time, etc. Small active recovery, suitable for large-scale production, and the effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the natural chicken egg white lysozyme of renaturation denaturation:

[0033] The ion-exchange chromatography column used in this example is a SP Sepharose Fast Flow prepacked column with a column volume of 5 mL;

[0034] The buffer solution for dissolving natural chicken egg white lysozyme is 0.05mol / L Tris-HCL, pH6.0, and contains 8mol / L urea and 0.1mol / L DTT;

[0035] Equilibrium, loading and washing buffer (mobile phase I) is 0.05mol / L Tris-HCL, pH6.0, and contains 6mol / L urea and 3mmol / L GSD, 0.3mmol / L GSSG;

[0036] The elution buffer (mobile phase II) is 0.1mol / L Tris-HCl, pH9.5, and contains 1mol / L urea, 0.3mol / L NaCl, 3mmol / L GSH, 0.3mmol / L GSSG;

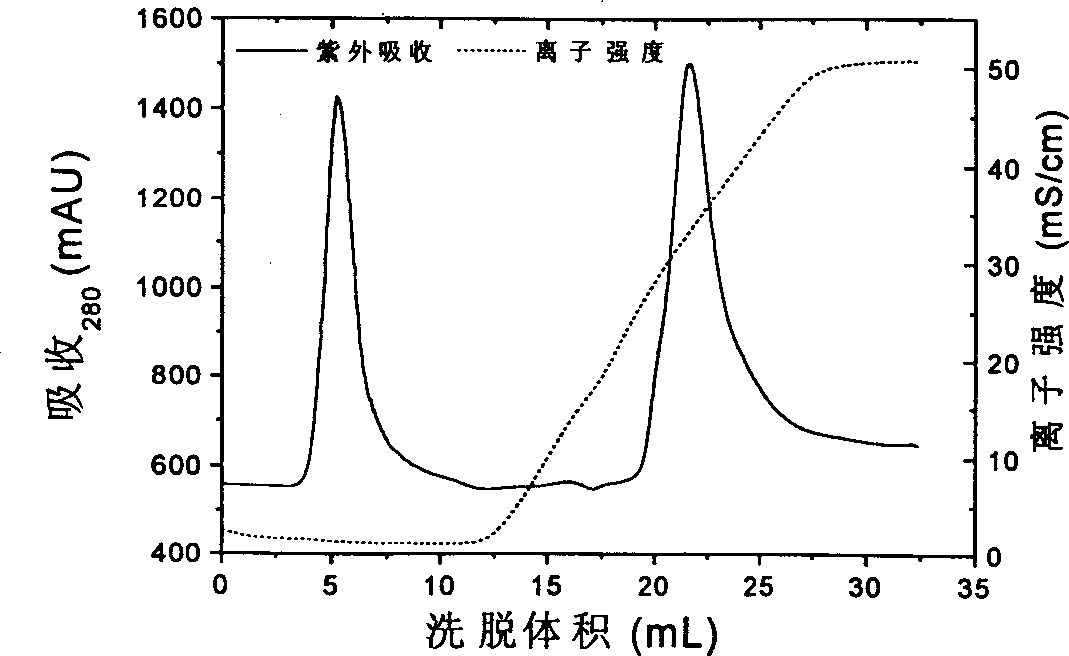

[0037] Loading 8mg of denatured natural chicken egg white lysozyme, the flow rate used is 0.4mL / min, a gradient of one column volume (5mL); the gradient of urea concentration in the process of denaturation and purification (from 6mol / L to 1mol / L) and A pH gradient (pH increase from 6 to 9.5) achieved ...

Embodiment 2

[0038] Example 2, renaturation and simultaneous purification of inclusion body protein Fe-SOD

[0039] The ion-exchange chromatography column used in this example is a Q Sepharose Fast Flow prepacked column with a volume of 5 mL;

[0040] The buffer solution for dissolving inclusion body protein Fe-SOD is 0.05mol / L PBS buffer solution, pH8.5, and contains 10mol / L urea and 3% Triton X-100;

[0041] Equilibration and injection buffer (mobile phase I) is 0.05mol / L PBS, pH8.5, and contains 6mol / L urea, 0.01mol / L FeCl 3 and 3% Triton X-100;

[0042] Elution buffer (mobile phase II) is 0.1mol / L PBS, pH6.5, and contains 1mol / L urea, 0.01mol / L FeCl 3 , 0.2% Triton X-100, 0.2mol / L NaCl;

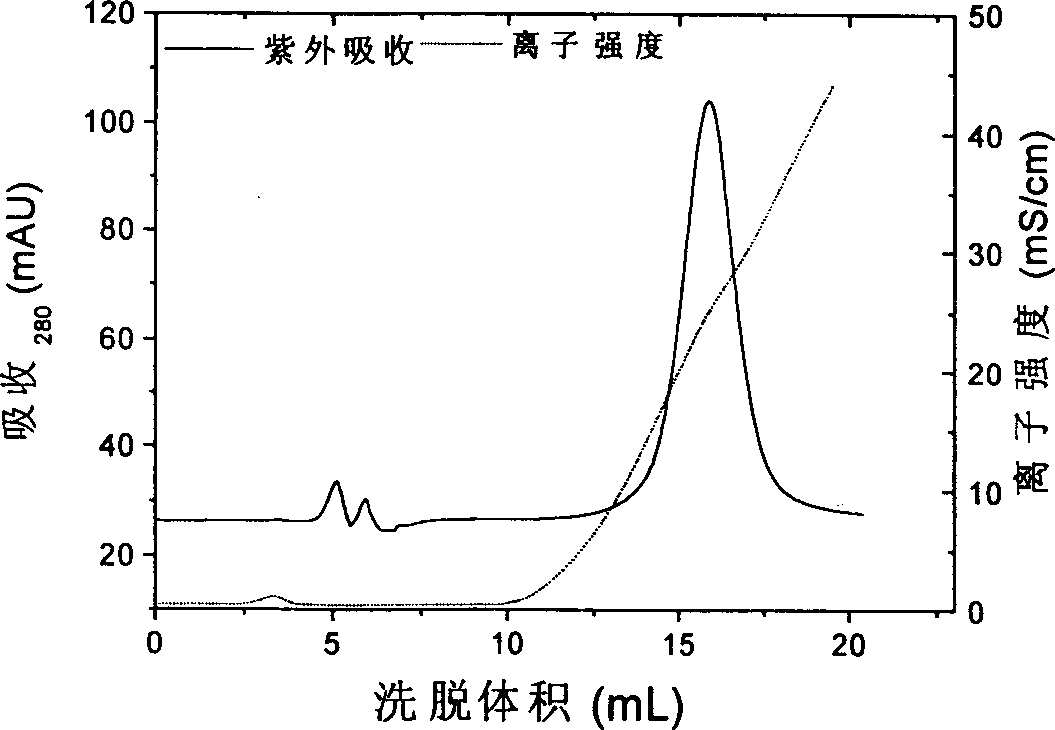

[0043] Load 4mg of inclusion body protein Fe-SOD refolding solution, flow rate of 0.3mL / min, gradient of two column volumes.

[0044] This process uses an elution buffer (mobile phase II) containing mixed denaturants (urea and Triton X-100), which increases the solubility of the inclusion body pro...

Embodiment 3

[0046] Example 3: Renaturation and Simultaneous Purification of Inclusion Body Protein Human Lysozyme

[0047] The ion exchange chromatography column used in this example is SP Sepharose Fast Flow 7mL;

[0048] The buffer solution for dissolving inclusion body protein is 0.05mol / L Tris-HCl, pH5.5, and contains 8mol / L urea and 0.1mol / L dithiothreitol (DTT);

[0049] Loading buffer (mobile phase I) is 0.05mol / L Tris-HCl, pH5.5, and contains 6mol / L urea, 3mmol / L GSH and 0.3mmol / L GSSG;

[0050] The elution buffer (mobile phase II) is 0.1mol / L Tris-HCl, pH10.0, and contains 1mol / L urea, 0.2mol / L (NH 4 ) 2 SO 4 , 3mmol / L GSH and 0.3mmol / L GSSG, the flow rate is 0.4mL / min, a gradient of one column volume, and 8mg of sample protein;

[0051] The average specific activity of the protein after renaturation is 42618U / mg, the protein yield is 98%, and the final protein concentration is 1-1.2mg / mL; the renaturation time is shortened from 8.5 hours for dilution renaturation to 2 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com