Method for treating hematite deironing tail gas

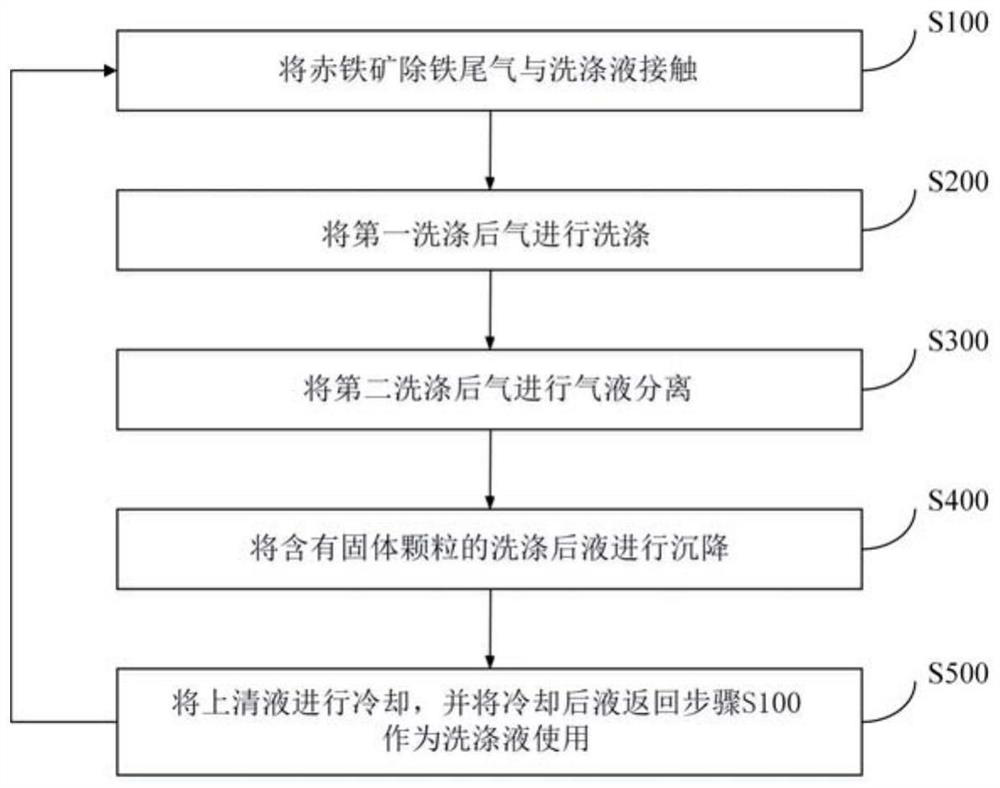

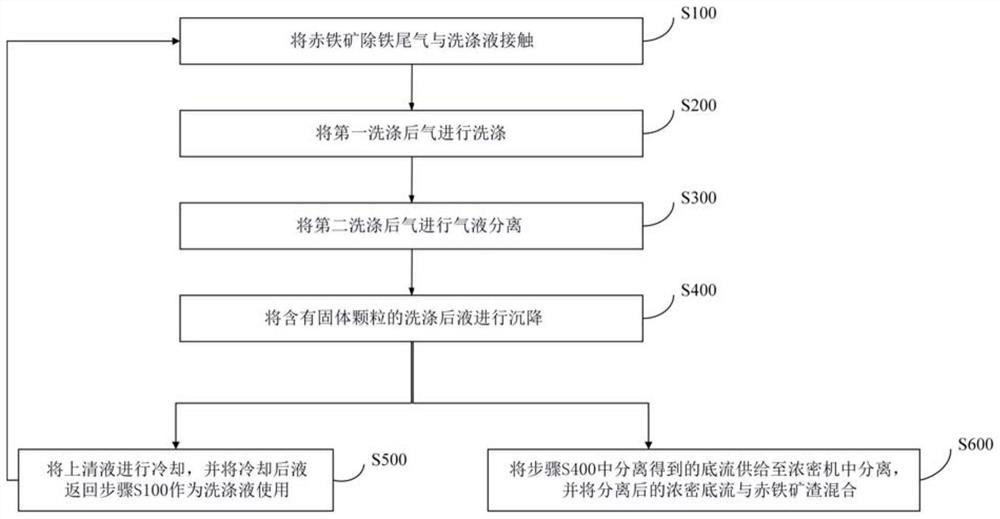

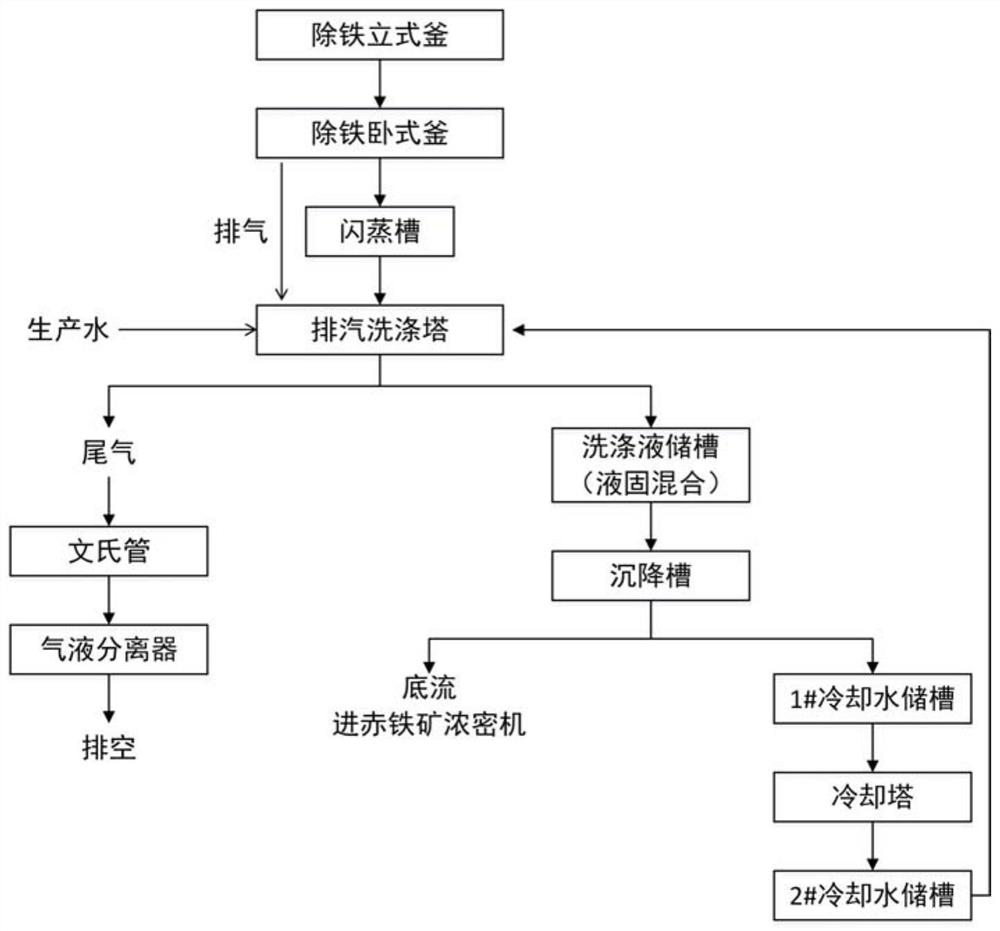

A hematite and tail gas technology, applied in the metallurgical field, can solve the problems of reducing the start-up rate, high solid content of the washing liquid, and large amount of fresh water, etc., and achieves the effect of improving the recycling rate, improving the washing efficiency and reducing the cleaning frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1: Send the hematite iron removal tail gas to the exhaust scrubber and use the produced water as the washing liquid for spraying to obtain the first washed gas and the washed liquid containing solid particles, wherein the hematite iron removal tail gas O 2 with Fe 2+ A mixture of residual gases and vapors after a reaction. The hematite iron removal tail gas includes O 2 , Fe 2 o 3 、H 2 SO 4 , ZnSO 4 Wait. The solid content of the hematite iron removal tail gas is 5g / L. The flow ratio of hematite iron removal tail gas to washing liquid is 1000:1;

[0046] Step 2: supplying the above-mentioned first scrubbed gas to the Venturi tube for intensive scrubbing to obtain the second scrubbed gas;

[0047] Step 3: supply the above-mentioned second washed gas to a gas-liquid separator for gas-liquid separation, obtain separated gas and separated liquid, and empty the separated gas;

[0048] Step 4: supply the washed liquid obtained in step 1 to a settling tank for ...

Embodiment 2

[0052] Step 1: Send the hematite iron removal tail gas to the exhaust scrubber and use the produced water as the washing liquid for spraying to obtain the first washed gas and the washed liquid containing solid particles, wherein the hematite iron removal tail gas O 2 with Fe 2+ A mixture of residual gases and vapors after a reaction. The hematite iron removal tail gas includes O 2 , Fe 2 o 3 、H 2 SO 4 , ZnSO 4 Wait. The solid content of the hematite iron removal tail gas is 3g / L. The flow ratio of hematite iron removal tail gas to washing liquid is 1200:1;

[0053] Step 2: supplying the above-mentioned first scrubbed gas to the Venturi tube for intensive scrubbing to obtain the second scrubbed gas;

[0054] Step 3: supply the above-mentioned second washed gas to a gas-liquid separator for gas-liquid separation, obtain separated gas and separated liquid, and empty the separated gas;

[0055] Step 4: supply the washed liquid obtained in step 1 to a settling tank for ...

Embodiment 3

[0059] Step 1: Send the hematite iron removal tail gas to the exhaust scrubber and use the produced water as the washing liquid for spraying to obtain the first washed gas and the washed liquid containing solid particles, wherein the hematite iron removal tail gas O 2 with Fe 2+ A mixture of residual gases and vapors after a reaction. The hematite iron removal tail gas includes O 2 , Fe 2 o 3 、H 2 SO 4 , ZnSO 4 Wait. The solid content of the hematite iron removal tail gas is 7g / L. The flow ratio of hematite iron removal tail gas to washing liquid is 900:1;

[0060] Step 2: supplying the above-mentioned first scrubbed gas to the Venturi tube for intensive scrubbing to obtain the second scrubbed gas;

[0061] Step 3: supply the above-mentioned second washed gas to a gas-liquid separator for gas-liquid separation, obtain separated gas and separated liquid, and empty the separated gas;

[0062] Step 4: supply the washed liquid obtained in step 1 to a settling tank for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com