Method for reclaiming and purifying titanium tetrachloride for preparing olefin polymerization catalysts

A technology of titanium tetrachloride and olefin polymerization, applied in the direction of titanium halide, etc., can solve the problems of low recovery rate of titanium tetrachloride, complicated process, inconvenient operation, etc., and achieve simplified impurity removal and purification process, high purity, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

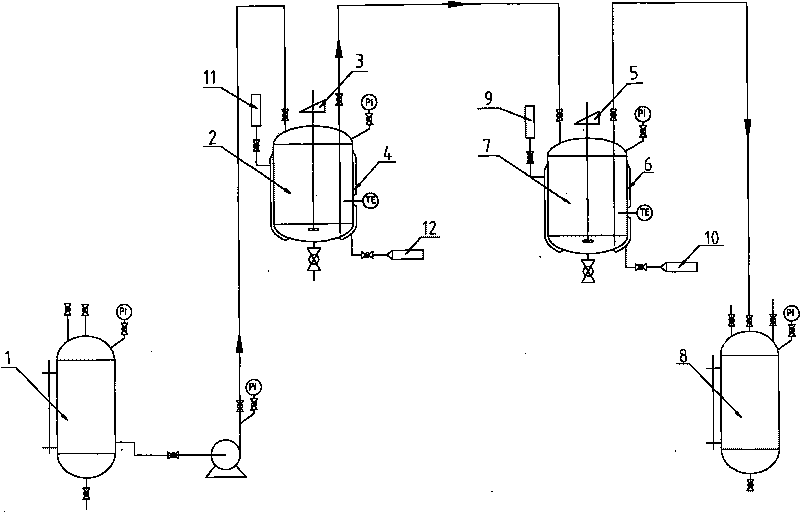

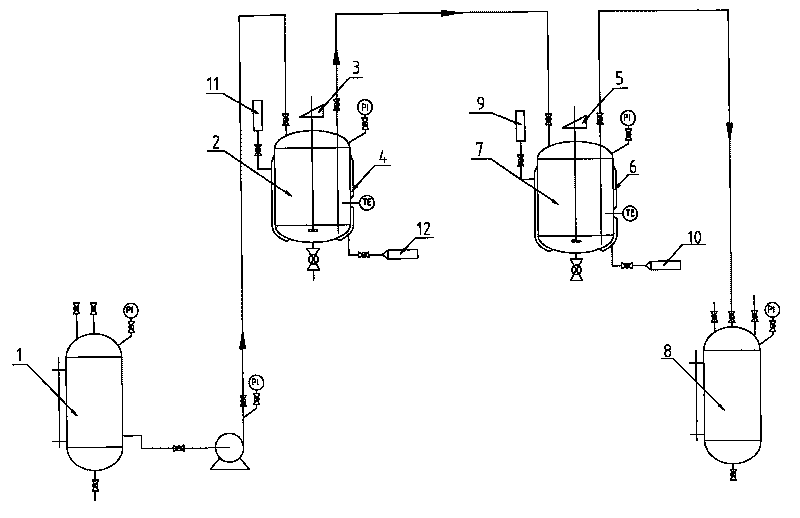

[0019] Such as figure 1 Shown, a kind of recovery purification device of titanium tetrachloride that prepares olefin polymerization catalyst: comprise intermediate storage tank I (1), pre-cooling still (2), cryogenic still (7) and intermediate storage tank II (8), Intermediate storage tank I (1), pre-cooling kettle (2), deep-cooling kettle (7) and intermediate storage tank II (8) are connected by pipelines; pre-cooling kettle (2) is provided with stirring blade I (3 ), the pre-cooling kettle (2) is provided with a water jacket (4); the cryogenic kettle (7) is provided with a stirring paddle II (5), and the cryogenic kettle (7) is provided with a refrigerant jacket (6).

[0020] The recovery and purification method of titanium tetrachloride for preparing olefin polymerization catalyst is as follows:

[0021] 1) Pretreatment: Add the titanium tetrachloride mother liquor produced during the preparation of the olefin polymerization catalyst into the intermediate storage tank I (1...

Embodiment 2

[0026] The recovery and purification device is the same as in Example 1.

[0027] The recovery and purification method of titanium tetrachloride for preparing olefin polymerization catalyst is as follows:

[0028] 1) Pretreatment: Add the titanium tetrachloride mother liquor produced during the preparation of the olefin polymerization catalyst into the intermediate storage tank I (1), and then enter the pre-cooling tank (2) through the pipeline, and the pre-cooling water at about 30°C passes through the water inlet (11) enter in the water jacket (4), circulate through the water outlet (12), stir, and the stirring speed is 100~300 rpm;

[0029] 2) Cold analysis and sedimentation: Transfer the pretreated titanium tetrachloride mother liquor into the cryogenic kettle (7), Freon at -35°C enters the refrigerant jacket (6) through the refrigerant medium inlet (9), and passes through the refrigerant medium (10) Carry out circulation, make the temperature of titanium tetrachloride mo...

Embodiment 3

[0033] The recovery and purification device is the same as in Example 1.

[0034] The recovery and purification method of titanium tetrachloride for preparing olefin polymerization catalyst is as follows:

[0035] 1) Pretreatment: Add the titanium tetrachloride mother liquor produced during the preparation of the olefin polymerization catalyst into the intermediate storage tank (1), water at about 10°C enters the water jacket (4) through the water inlet (11), and passes through the water Outlet (12) is circulated, stirred, and the stirring speed is 100~300 revs / min;

[0036] 2) Cold analysis and sedimentation: Transfer the pretreated titanium tetrachloride mother liquor into the cryogenic kettle (7), and the frozen brine at about -5°C enters the refrigerant jacket (6) through the refrigerant medium inlet (9), and passes through The refrigerant medium outlet (10) is circulated to gradually reduce the temperature of the titanium tetrachloride mother liquor to between 0°C and -5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com