Fused salt chlorination furnace for producing titanium tetrachloride

A molten salt chlorination furnace, titanium tetrachloride technology, applied in the direction of titanium halide, to achieve the effect of preventing leakage and improving the properties of molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

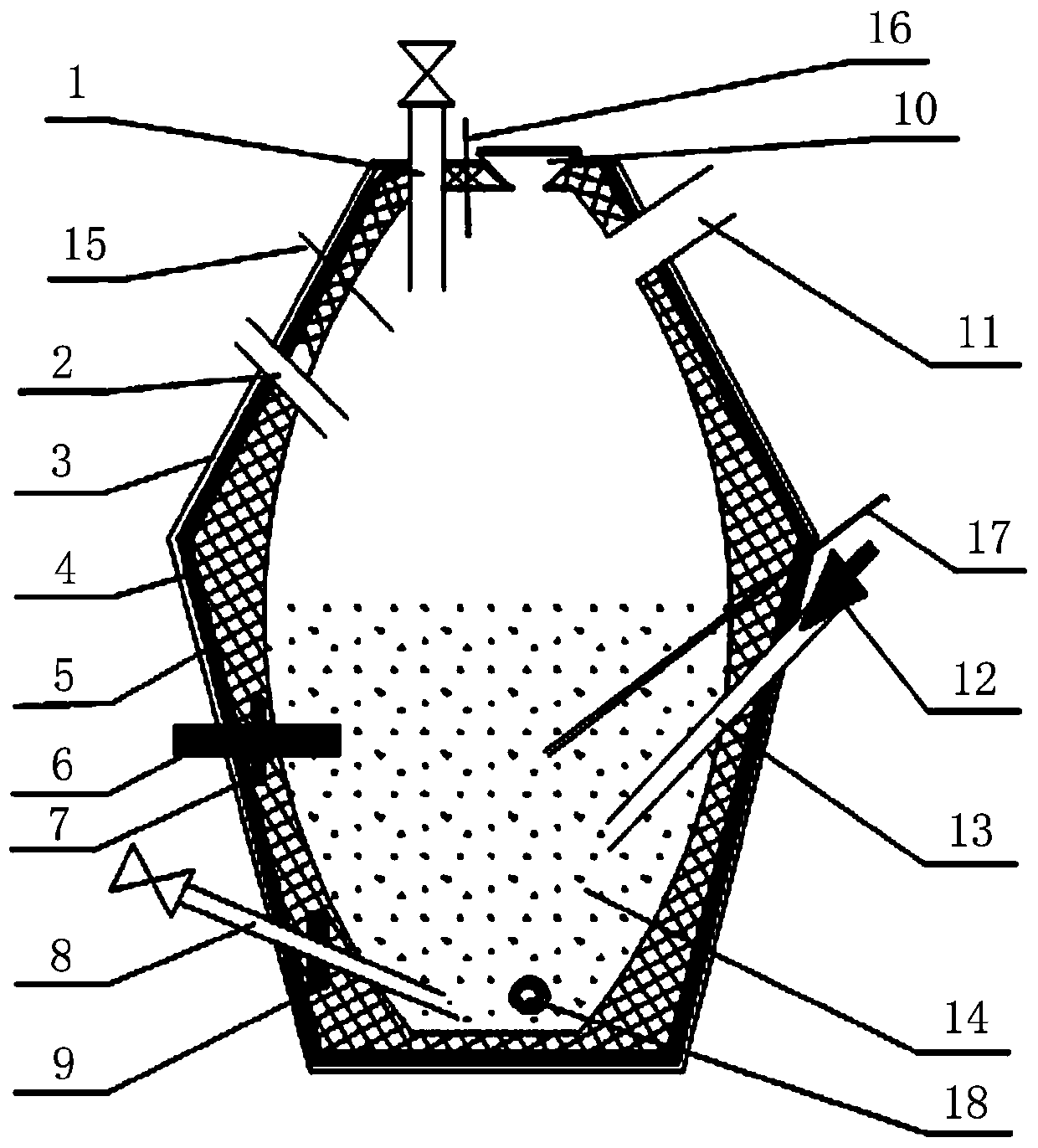

[0019] Hereinafter, the structure of a molten salt chlorination furnace for producing titanium tetrachloride according to an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0020] figure 1 It is a structural schematic diagram of a molten salt chlorination furnace for producing titanium tetrachloride according to an exemplary embodiment of the present invention. Such as figure 1 As shown, the top of the molten salt chlorination furnace producing titanium tetrachloride of the present invention is provided with a slurry return pipe 1, a feeding pipe 2, an explosion-proof port 10 and a product mixed steam outlet 11, wherein the feeding pipe 2 is used for Add solid raw materials such as titanium slag into the furnace. The explosion-proof port 10 is used for exhausting and explosion-proof and for adding high-temperature liquid molten salt. The slurry return pipe 1 is used for spraying Liquid titanium tetrachl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com