Cathode active material for nonaqueous electrolyte secondary battery and method of producing cathode active material for nonaqueous electrolyte secondary battery

A positive active material and non-aqueous electrolyte technology, which is applied in the field of non-aqueous electrolyte secondary batteries, and can solve problems such as the reversible capacity limit of the theoretical capacity of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0033] The first embodiment will be described.

[0034] In this embodiment, the alkali metal fluoride (A is Na or Li) represented by the formula AF and the transition metal fluoride M'F 2 or M'F 3 (M' represents a transition element) is mechanically ground to produce a perovskite-type fluorine-containing compound AM'F 3 and / or AM'F 4 . The fluoride AM'F 3 and / or AM'F 4 It is used as a positive electrode active material contained in a positive electrode of a nonaqueous electrolyte secondary battery. Here, as long as the transition metal fluoride contains the transition metal as M', from M'F 2 or M'F 3 The indicated compounds can be used. From the viewpoint of being used as a positive electrode active material for a non-aqueous electrolyte secondary battery, the transition metal fluoride preferably contains a fluoride in which the transition element M' is at least one selected from V, Ti, Fe, Ni, Co or Mn . That is, the transition metal fluoride preferably comprises VF...

Embodiment 1

[0053] (Positive electrode active material (Na-containing perovskite-type fluorine compound AM'F 3 ) preparation)

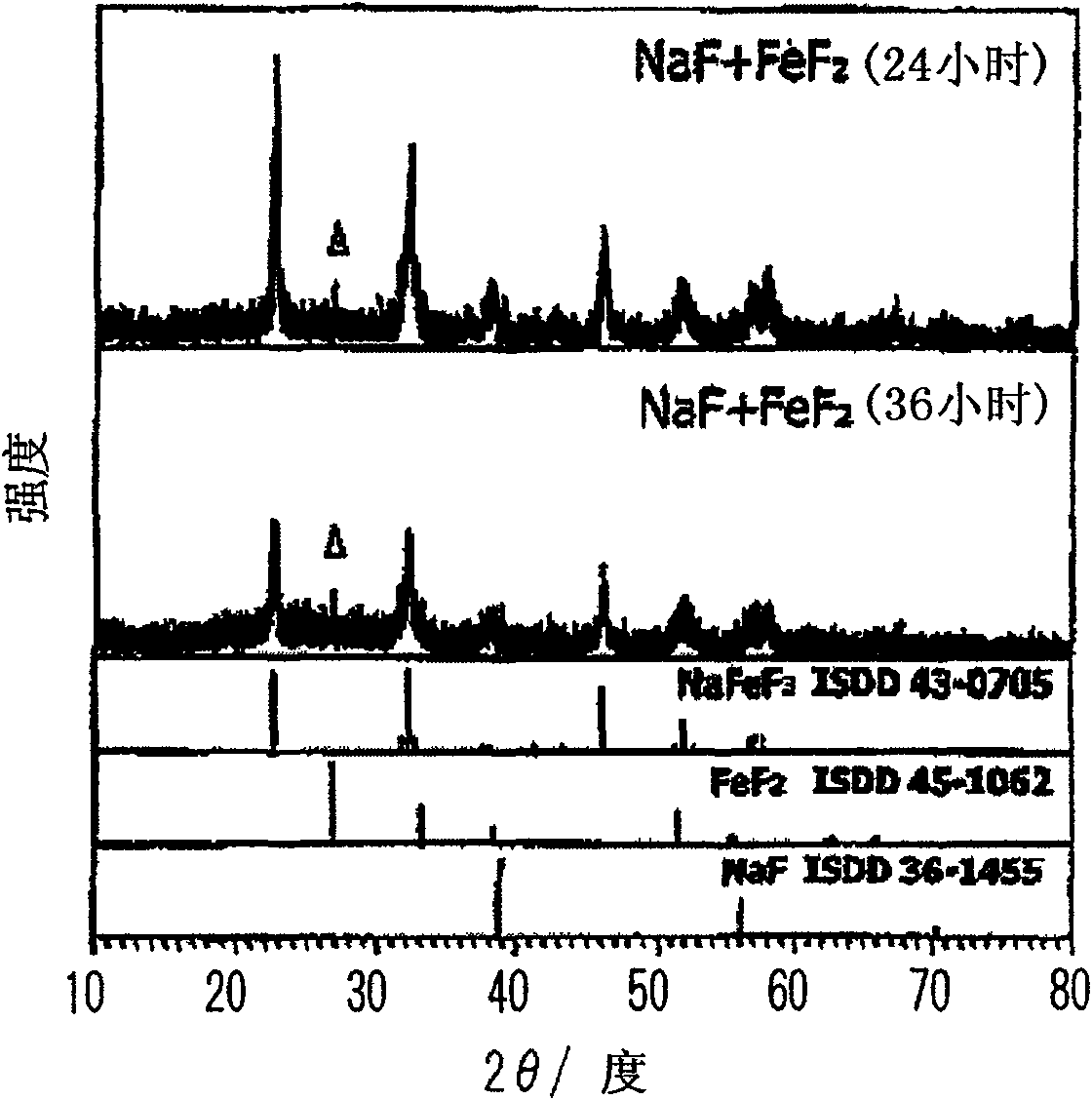

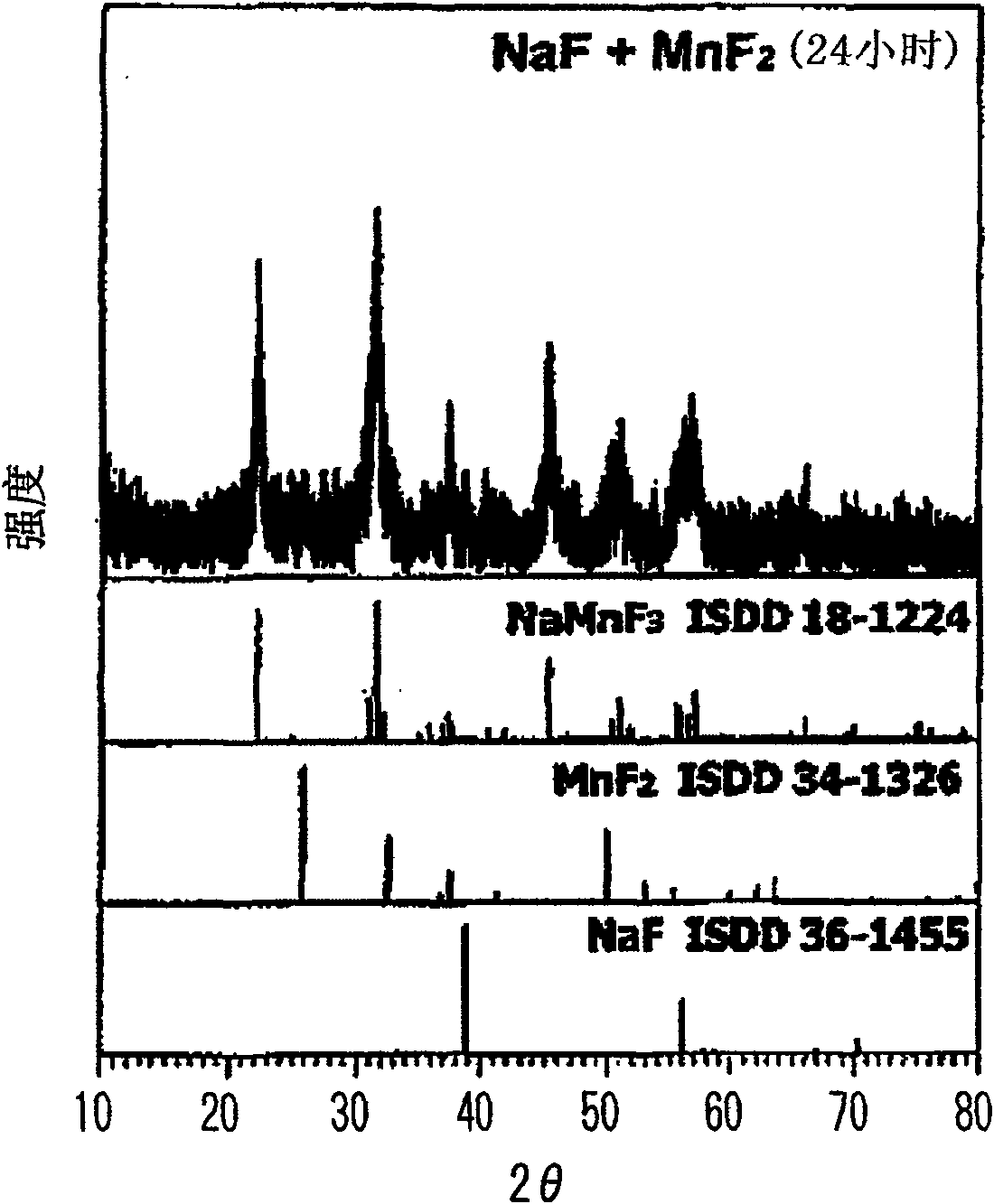

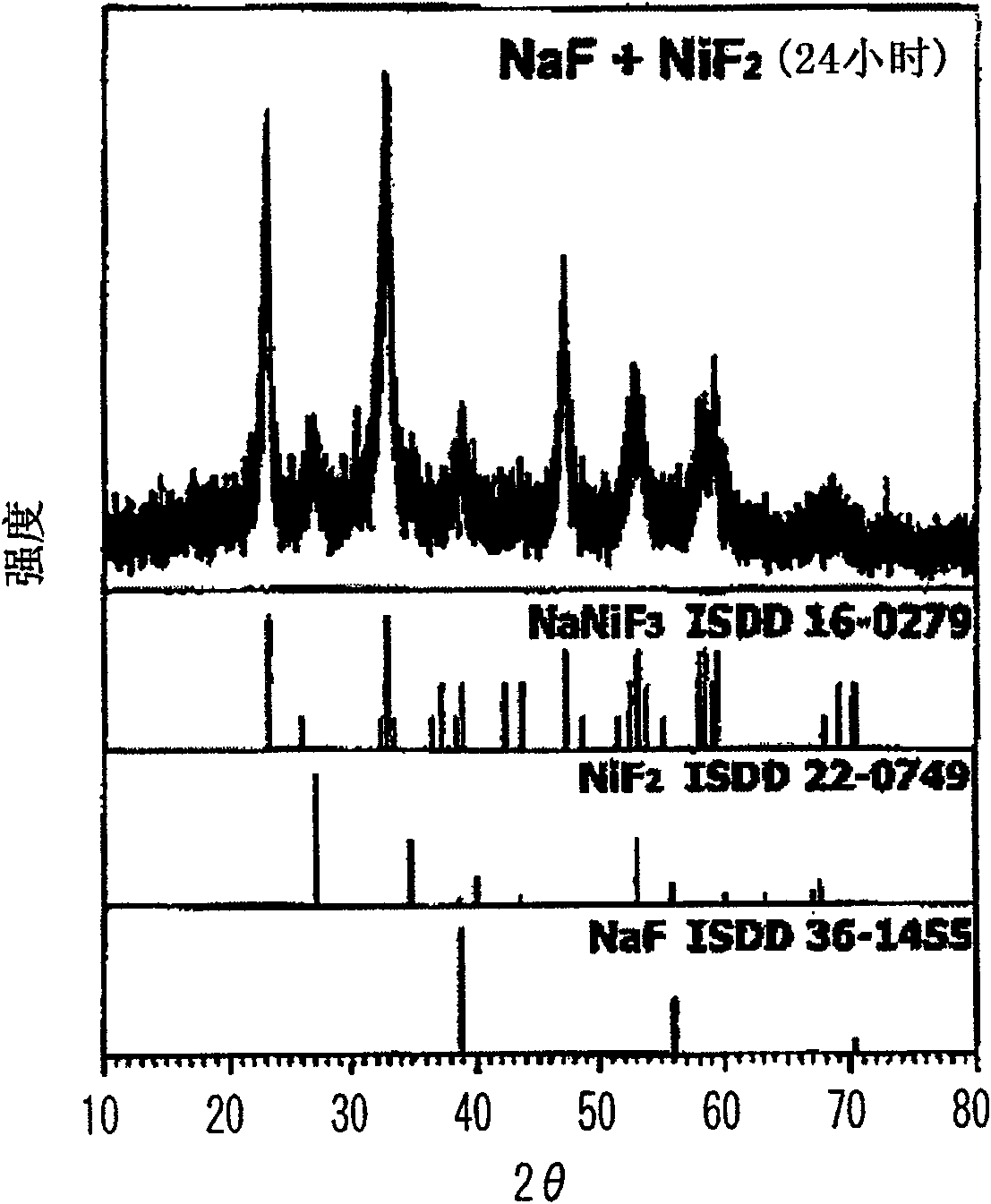

[0054] Sodium fluoride (NaF) and transition metal fluoride M'F 2 (M' is any one of Fe, Ni, Mn) equimolar mixture as raw material, using planetary ball mill to carry out mechanical grinding process. Raw materials were all 99% pure, and raw materials manufactured by Wako Pure Chemical Industries, Ltd. or Soekawa Rika Co., Ltd. were used. As the planetary ball mill, a planetary rotary mixer for experiments (planetary return port mill for 実験) LP-4 / 2 (manufactured by Ito Seisakusho Co., Ltd.) was used. Two balls with a diameter of 20 mm, four balls with a diameter of 15 mm, and 15 balls with a diameter of 10 mm were placed in an 80 ml ball mill jar, and 3 mm balls were placed so as to add up to 175 g in total. Raw materials were further charged into the ball milling pot, and the ball milling pot was rotated at a rotation speed of 200 rpm. The treatment time was se...

Embodiment 2

[0060] (Measurement of battery characteristics)

[0061] To the NaFeF synthesized with embodiment 1 3 (Product of 24-hour treatment) The characteristics of a nonaqueous electrolyte battery as a positive electrode active material were evaluated.

[0062] Figure 4 It is a schematic diagram showing the structure of the assembled non-aqueous electrolyte secondary battery. This nonaqueous electrolyte secondary battery includes a positive electrode 1 , a negative electrode 2 , a positive electrode container 4 , a negative electrode cover 5 , a separator, and an electrolytic solution 3 (separator impregnated with the electrolytic solution 3 ). The positive electrode 1 and the negative electrode 2 are inserted into the positive electrode container 4 with a separator sandwiched between the positive electrode 1 and the negative electrode 2 .

[0063] In order to manufacture the positive electrode 1, the positive electrode active material prepared in Example 1, the conductive materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com