Preparation method of bacterial cellulose-nano silver composite material

A technology of bacterial cellulose and composite materials, applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of operation cost, safety and toxicity, etc., and achieve reduced agglomeration, uniform distribution, and small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

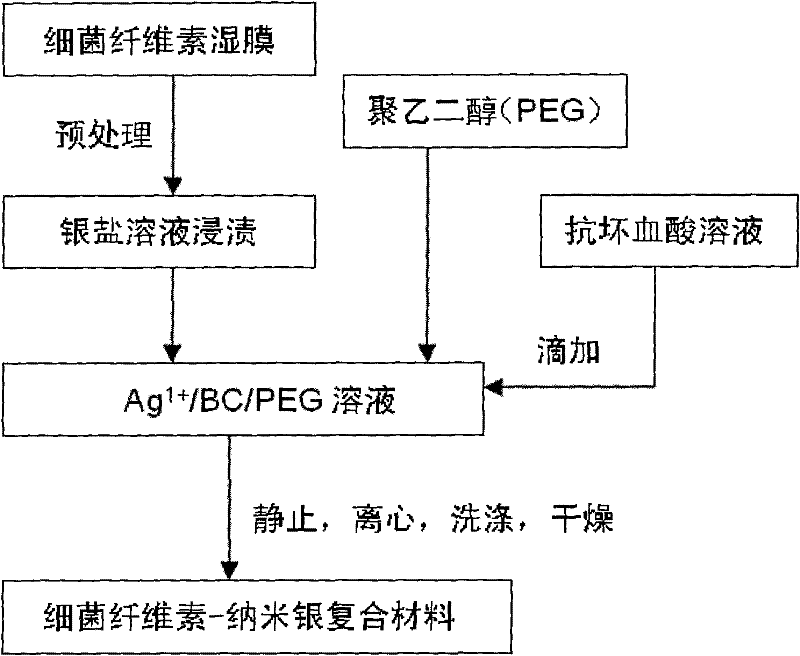

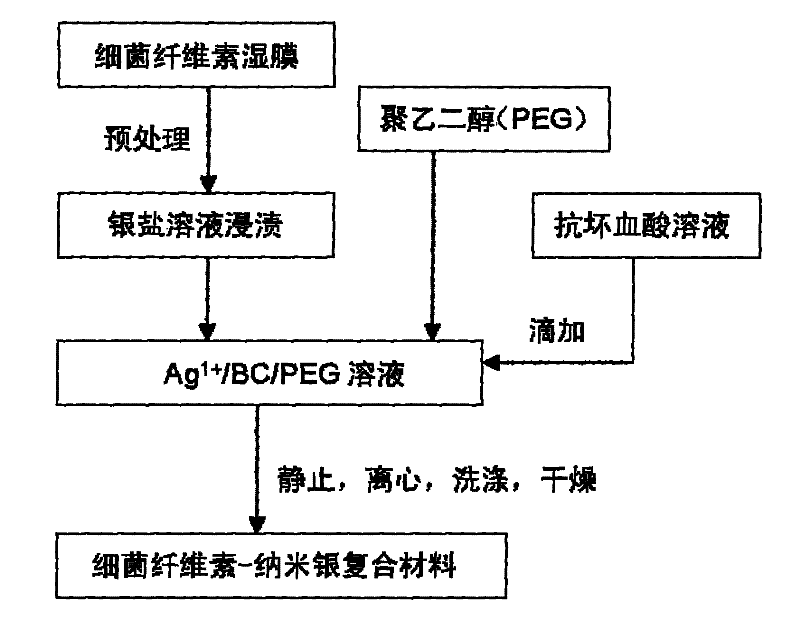

[0013] In conjunction with accompanying drawing, the preparation method of bacterial cellulose-nano-silver composite material of the present invention may further comprise the steps:

[0014] In the first step, the bacterial cellulose wet film is crushed and then added to an alkaline solution to boil. The alkaline solution is a mixture of one or more of sodium hydroxide, sodium carbonate, potassium hydroxide, and potassium carbonate solutions, and the concentration of the alkaline solution is 0.5 -2.0%, then neutralize with acetic acid solution, the concentration of acetic acid solution is 1.0-2.0%. Then wash with deionized water until neutral;

[0015] In the second step, the product obtained in the first step is immersed in a silver salt solution, the silver salt is silver nitrate or silver 2-ethylhexanoate, the concentration of the silver salt solution is 0.0012-0.6mol / L, and then filtered or centrifuged to obtain solid, then washed with deionized water;

[0016] In the t...

Embodiment 1

[0022] Implementation example 1: the preparation method of bacterial cellulose-nanometer silver composite material of the present invention may further comprise the steps:

[0023] The first step is to crush 5g bacterial cellulose wet film, add 0.5% NaOH solution, boil for 1-2 hours, then treat with 1.0% acetic acid solution for 20-30 minutes, and then wash with deionized water until neutral ;

[0024] In the second step, the product obtained in the first step is placed in 0.6mol / L AgNO 3 Soak in solution (25mL), stir at room temperature for 2-3 hours, filter or centrifuge to obtain a solid, and then wash with deionized water for 3 times;

[0025] In the third step, the product of the second step is transferred to 0.5% polyethylene glycol aqueous solution (50mL), stirred for 1-2 hours and then placed in an ice bath. When the temperature of the reaction system is lower than 5°C, start to drop 0.5mol / L of ascorbic acid solution vitamin C (50mL) the whole reaction process does...

Embodiment 2

[0029] Implementation example 2: the preparation method of bacterial cellulose-nano-silver composite material of the present invention may further comprise the steps:

[0030] In the first step, after pulverizing 5g bacterial cellulose wet film, add 2.0% sodium carbonate solution, boil for 0.5-1 hour, then treat with 2.0% acetic acid solution for 30-50 minutes, and finally wash with deionized water until medium sex;

[0031] In the second step, the product obtained in the first step is placed in 0.0012mol / L AgNO 3 Soak in solution (25mL), stir at room temperature for 2-3 hours, filter or centrifuge to obtain a solid, and then wash with deionized water for 3 times;

[0032] In the third step, the product of the second step is transferred to 0.01% polyethylene glycol aqueous solution (50mL), stirred for 2-3 hours and then placed in an ice bath. When the temperature of the reaction system is lower than 5°C, start to drop 0.1mol / L of ascorbic acid solution (5mL) the whole react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com