Catalyst for hydrogen production through catalytic cracking of methane and its preparation method

A methane catalysis and catalyst technology, which is applied in the field of nickel-based methane cracking hydrogen production catalyst and its preparation, achieves the effects of high methane conversion rate, reduced agglomeration, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

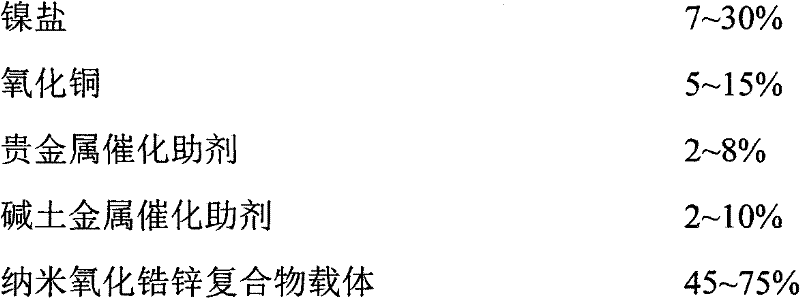

[0027] The components and weight fractions of a methane catalytic cracking hydrogen production catalyst are:

[0028]

[0029] Wherein: the nickel salt is nickel acetate; the precious metal catalyst promoter is palladium; the alkaline earth metal promoter is lithium; the diameter of the nano-zirconia-zinc composite carrier is 40 nanometers, and the molar weight of the element zirconium: the ratio of the molar weight of the element zinc is 1 : 4.

[0030] A kind of preparation method of methane catalytic cracking hydrogen production catalyst concrete steps are as follows:

[0031] (1) Preparation of nano-zirconia zinc composite carrier

[0032]First press the molar weight (mol) of zirconium ion in zirconium nitrate: the molar weight (mol) of zinc ion in zinc acetate: the ratio of the hydroxide radical molar weight (mol) of sodium hydroxide is the ratio of 1: 4: 6, first Add zirconium nitrate and zinc acetate to the alkaline precipitant, adjust its pH to 8 with sodium hydro...

Embodiment 2

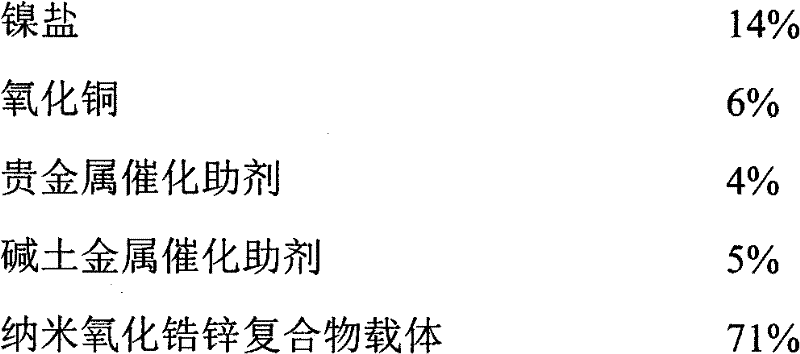

[0038] The components and weight fractions of a methane catalytic cracking hydrogen production catalyst are:

[0039]

[0040] Wherein: the nickel salt is nickel nitrate; the precious metal catalyst promoter is platinum; the alkaline earth metal promoter is calcium; the diameter of the nano-zirconia-zinc composite carrier is 30 nanometers, and the molar weight of element zirconium: the molar weight ratio of element zinc is 1 : 3.

[0041] A kind of preparation method of methane catalytic cracking hydrogen production catalyst, with embodiment 1, wherein:

[0042] In the (1) step, zirconium salt is zirconium oxychloride, and zinc salt is zinc nitrate, and alkaline precipitation agent is ammonium carbonate, and the molar weight (mol) of zirconium ion in zirconium oxychloride: the mole of zinc ion in zinc nitrate Amount (mol): the ratio of the hydroxide molar mass (mol) of ammonium carbonate is 1: 3: 10, the pH value is 9, the time for standing and aging is 15h, and the drying...

Embodiment 3

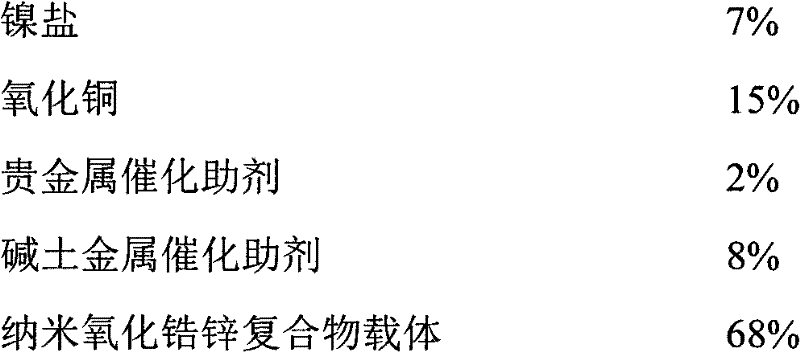

[0046] The components and weight fractions of a methane catalytic cracking hydrogen production catalyst are:

[0047]

[0048] Wherein: the nickel salt is nickel chloride; the noble metal catalyst promoter is ruthenium and gold; the alkaline earth metal promoter is sodium and barium; the diameter of the nano-zirconia-zinc composite carrier is 60 nanometers, and the molar weight of the element zirconium: the molar weight of the element zinc The amount ratio is 1:10.

[0049] A kind of preparation method of methane catalytic cracking hydrogen production catalyst, with embodiment 1, wherein:

[0050] In the (1) step, zirconium salt is zirconium chloride, and zinc salt is zinc sulfate, and alkaline precipitation agent is urea, and the molar weight (mol) of zirconium ion in zirconium chloride: the molar weight (mol) of zinc ion in zinc sulfate ): the ratio of the hydroxide root molar weight (mol) of urea is 1: 10: 12, the pH value adjusted with sodium hydroxide is 10, the time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com