Modified graphene adsorbent as well as preparation method and application thereof

A graphene and adsorbent technology, applied in the field of modified graphene adsorbent and its preparation, can solve problems such as limiting pollutant removal application, unfavorable dispersion, reducing graphene specific surface area, etc., and achieves improved dispersibility and hydrophilicity. , The effect of low processing cost and easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

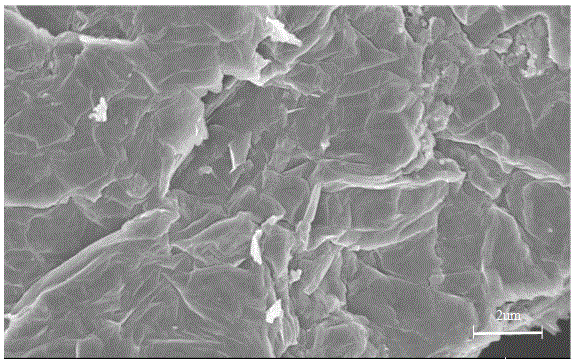

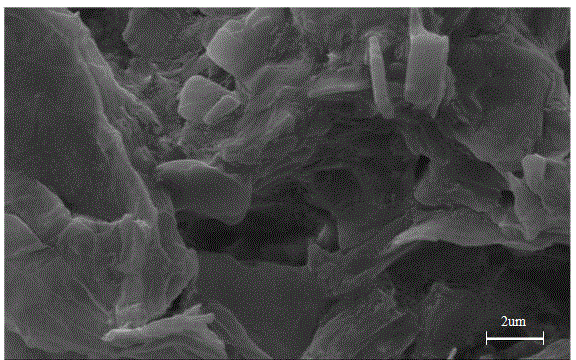

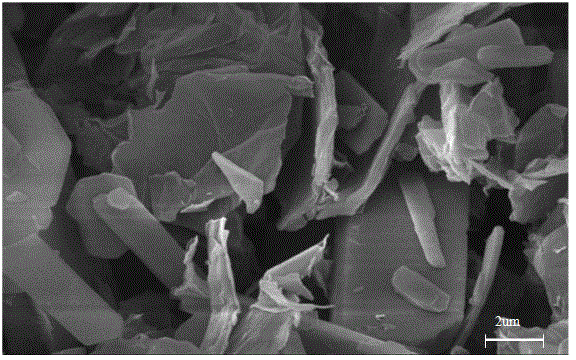

Image

Examples

Embodiment 1

[0037] The preparation method of the modified graphene adsorbent of the present embodiment may further comprise the steps:

[0038] (1) Disperse graphene oxide in water, and obtain a graphene oxide suspension with a concentration of 4 mg / mL after ultrasonic dispersion for 30 min;

[0039] The graphene oxide of the present embodiment is synthesized by the modified Hummers method, and the specific steps are as follows: 10 g of graphite and 5 g of sodium nitrate are slowly added into a flask containing 230 mL of concentrated sulfuric acid, and stirred in an ice-water mixture. After 30 min, slowly add 30 g of sodium nitrate. g potassium permanganate, during the stirring process, control the reaction temperature to always be less than 15°C, and keep it for 90 minutes; transfer the reaction system to a constant temperature water bath at 35°C, keep the reaction temperature at 35°C, and stir for 30 minutes; add 460mL of deionized water, the reaction temperature is controlled at 80 ℃ ~...

Embodiment 2

[0047] The preparation method of the modified graphene adsorbent of the present embodiment may further comprise the steps:

[0048] (1) Disperse graphene oxide in water, and obtain a graphene oxide suspension with a concentration of 6 mg / mL after ultrasonic dispersion for 60 min;

[0049] (2) Add aluminum hydroxide and surfactant polyacrylamide to the graphene oxide suspension obtained in step (1); wherein, the mass ratio of aluminum hydroxide, graphene oxide and polyacrylamide is 2:3:8, fully Stir, react at 60°C for 5 h, and obtain a reaction solution after complete reaction;

[0050] (3) Heating the reaction solution obtained in step (2) to 85°C, adding a reducing agent potassium borohydride, and obtaining a black flocculent precipitate after sufficient reaction; the mass of the reducing agent is 9 times the mass of graphene oxide;

[0051] (4) Suction filter, wash and dry the black flocculent precipitate obtained after step (3) to obtain a polyacrylamide-modified graphene ...

Embodiment 3

[0056] The preparation method of the modified graphene adsorbent of the present embodiment may further comprise the steps:

[0057] (1) Disperse graphene oxide in water, and obtain a graphene oxide suspension with a concentration of 5 mg / mL after ultrasonic dispersion for 40 min;

[0058] (2) Add aluminum hydroxy and surfactant sodium dodecylbenzene sulfonate to the graphene oxide suspension obtained in step (1); wherein, aluminum hydroxy, graphene oxide and sodium dodecylbenzene sulfonate The mass ratio is 2:3:10, fully stirred, reacted at 62°C for 4 h, and obtained a reaction solution after complete reaction;

[0059] (3) Heating the reaction solution obtained in step (2) to 82°C, adding a reducing agent sodium borohydride, and obtaining a black flocculent precipitate after fully reacting; the total mass of the reducing agent is 11 times the mass of graphene oxide;

[0060] (4) Suction filter, wash and dry the black flocculent precipitate obtained after step (3) to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com