Circuit breaker trolley operating connector with stop control function

A circuit breaker and trolley technology, which is applied in the direction of electrical components, switchgear, pull-out switchgear, etc., can solve the problem of wasting time, manpower, material resources and economic costs, and consumption of 10kV circuit breaker handcarts in and out. Overhaul, operation and maintenance personnel physical strength and other issues, to achieve the effect of simple structure, fewer operators, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

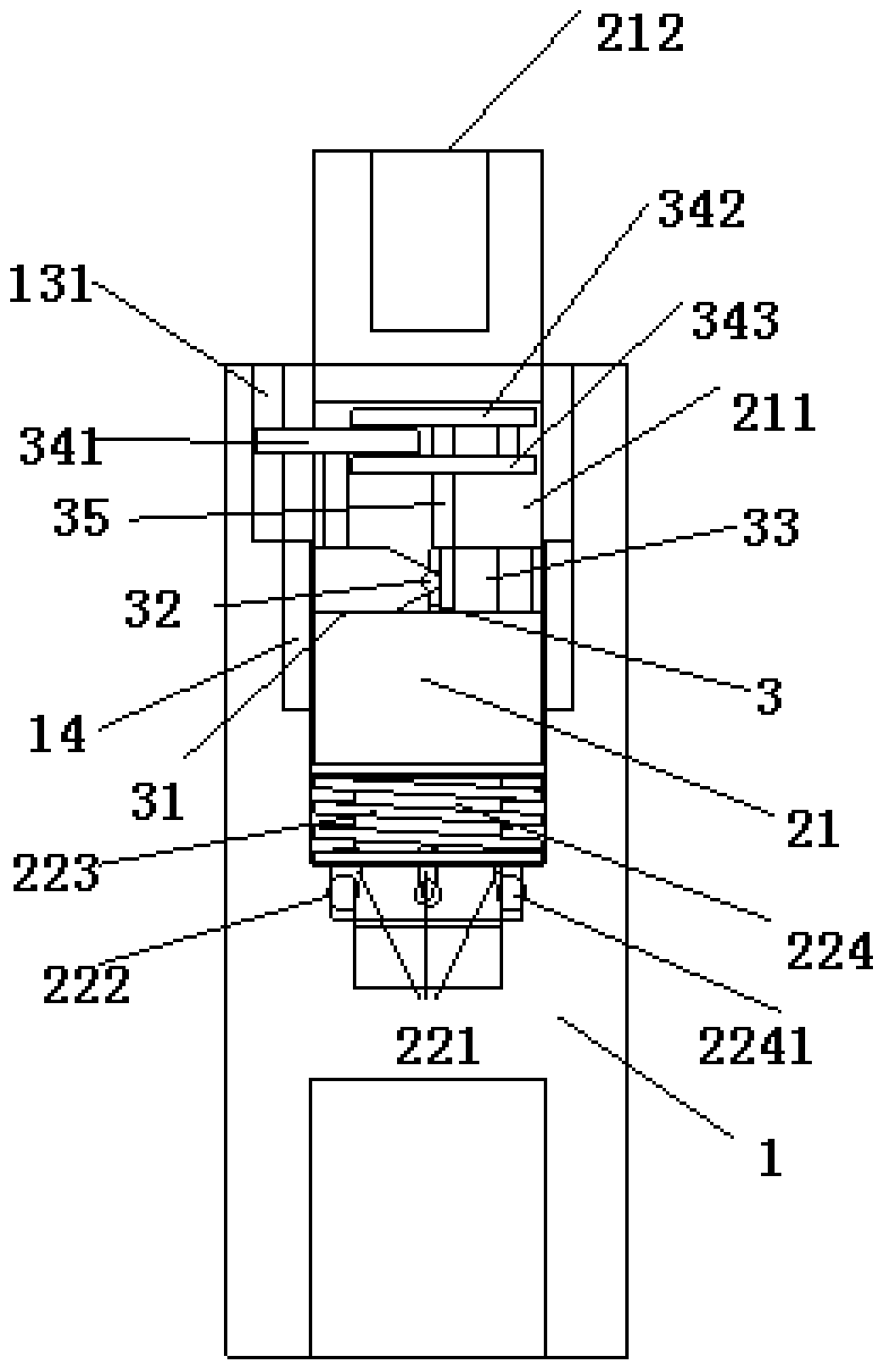

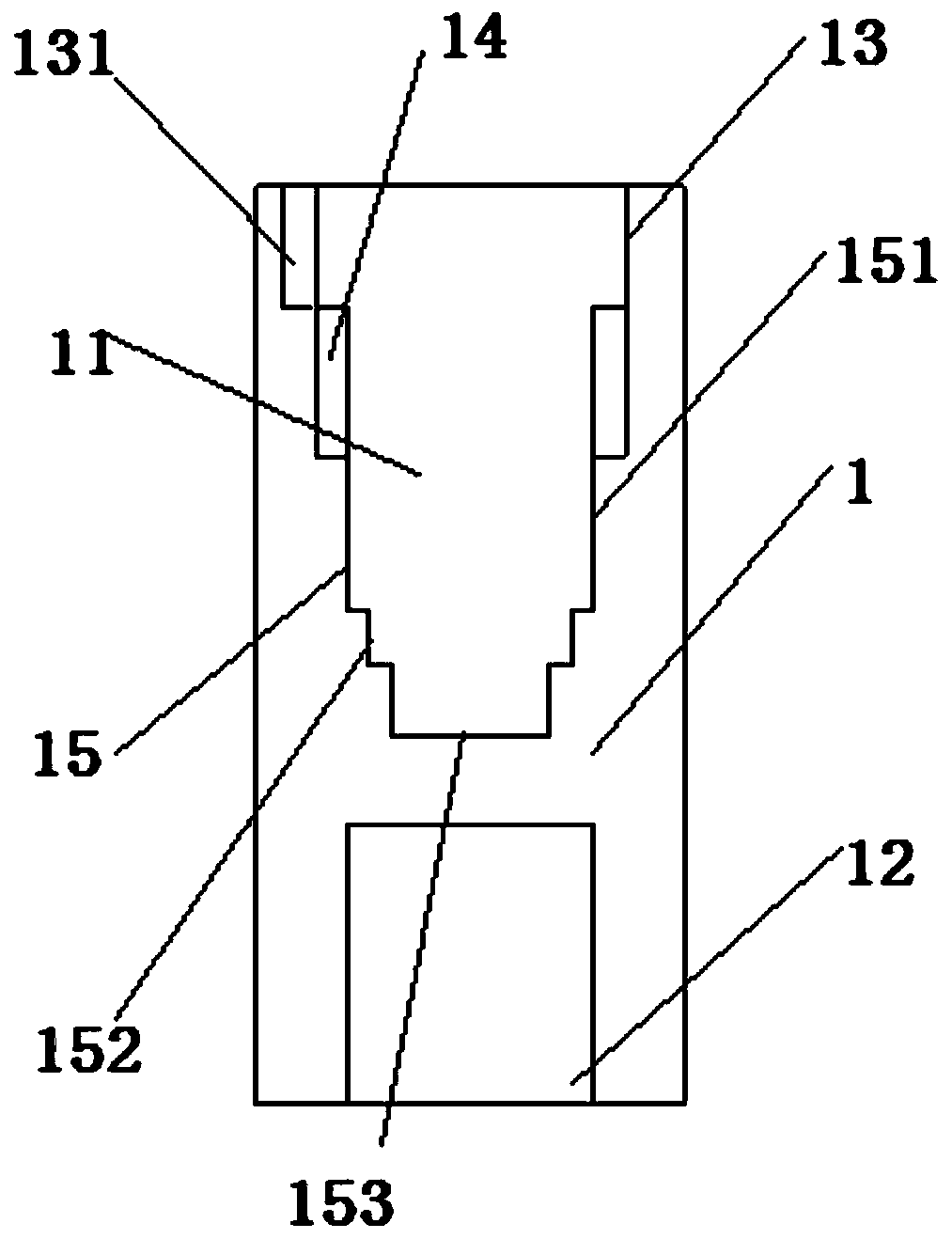

[0040] Such as Figure 1-8 As shown, a circuit breaker trolley operating joint with a stop control function in this embodiment is suitable for a 10kV circuit breaker trolley, including a connecting sleeve 1 , a drive shaft 2 and an intermediate mechanism 3 .

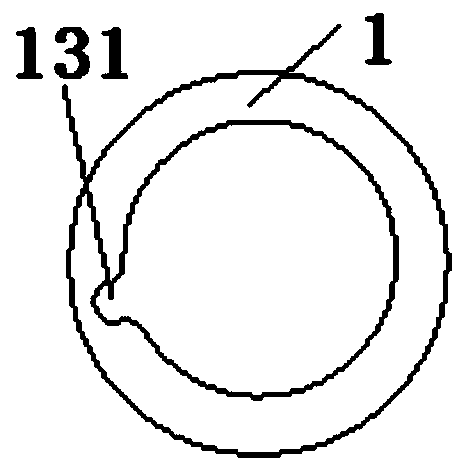

[0041] The connection sleeve 1 is specifically a connection sleeve 1 with upper and lower openings through. The middle part of the connection sleeve 1 is provided with a partition, which divides the connection sleeve into an upper accommodation chamber 11 and a lower accommodation chamber 12. The upper accommodation chamber 11 is fitted with a drive shaft 2 , The lower housing chamber 12 is equipped with a circuit breaker trolley. The inner wall of the upper chamber 11 is formed with three grooves, which are the first groove 13, the tiger claw groove 14 arranged at the lower end of the first groove 13, and the extension shaft movable groove 15 arranged at the lower end of the tiger claw groove 14; wherein, The aperture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com