Method for preparing sulfur/carbon composite cathode material for lithium-sulfur battery on basis of palm fiber

A palm fiber, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of difficult pore size adjustment, poor rate performance, and high cost, and achieve increased sulfur loading, high pore volume, and high pore volume. Larger than surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

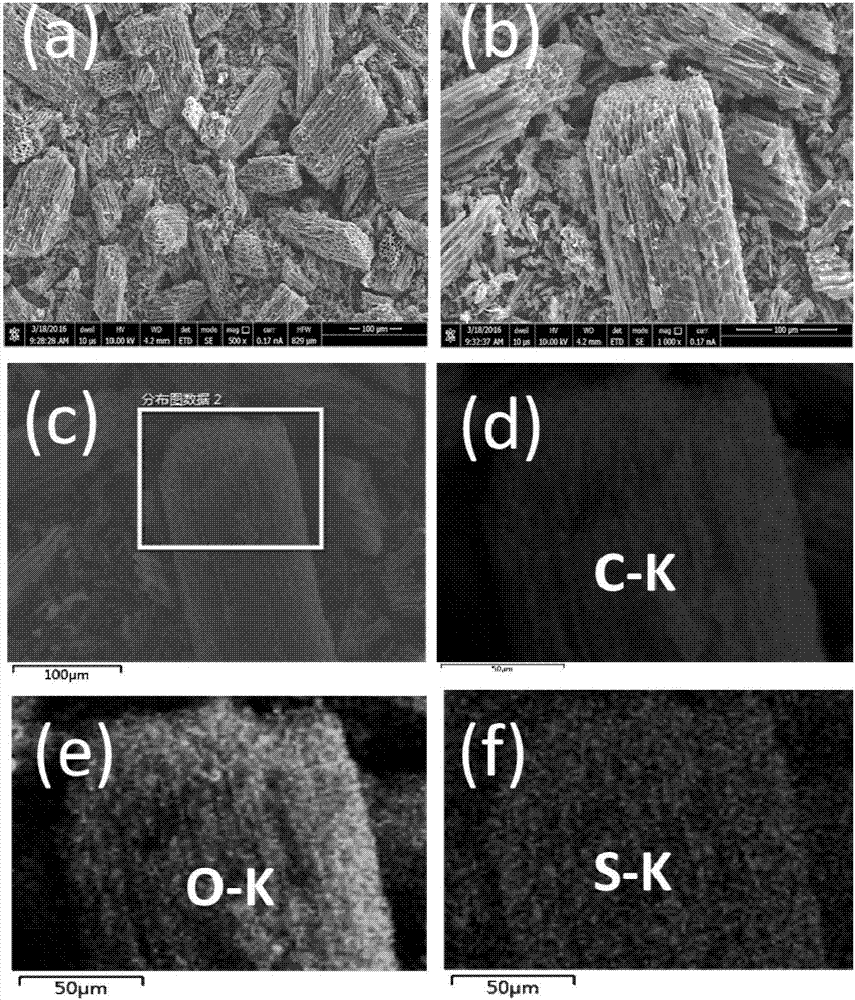

[0044] The preparation embodiment of palm fiber base activated carbon (AC):

[0045] 1) Carbon source pretreatment: Palm fibers are washed with a large amount of tap water and secondary water in turn, then dried in an oven at 120°C for 24 hours, and finally shredded to 2-3mm for later use.

[0046] 2) Carbonization: Weigh the above carbon source, in nitrogen atmosphere, 10°C·min -1 Heat up and keep warm at 500°C for 2h.

[0047] 3) Activation: according to m 炭化料 :m KOH = 1:4 ratio weighed and fully ground evenly, then placed in a graphite tank, activated in a vacuum tube furnace, the activation conditions were nitrogen atmosphere, 10 ° C min -1 Heat up and keep warm at 900°C for 1h.

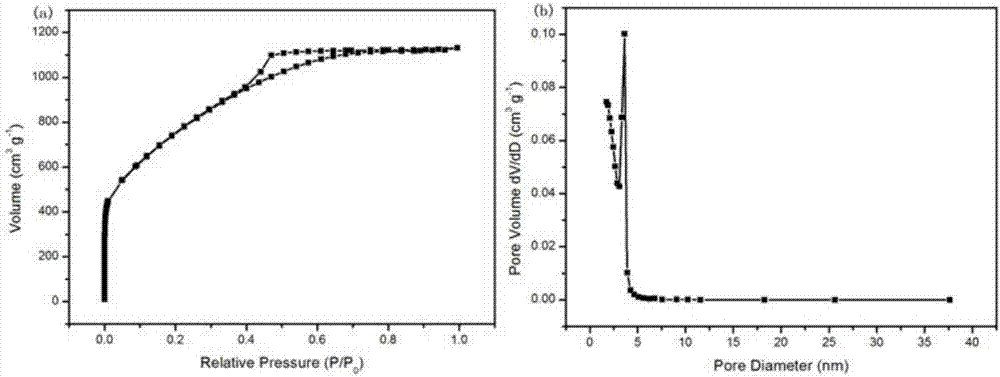

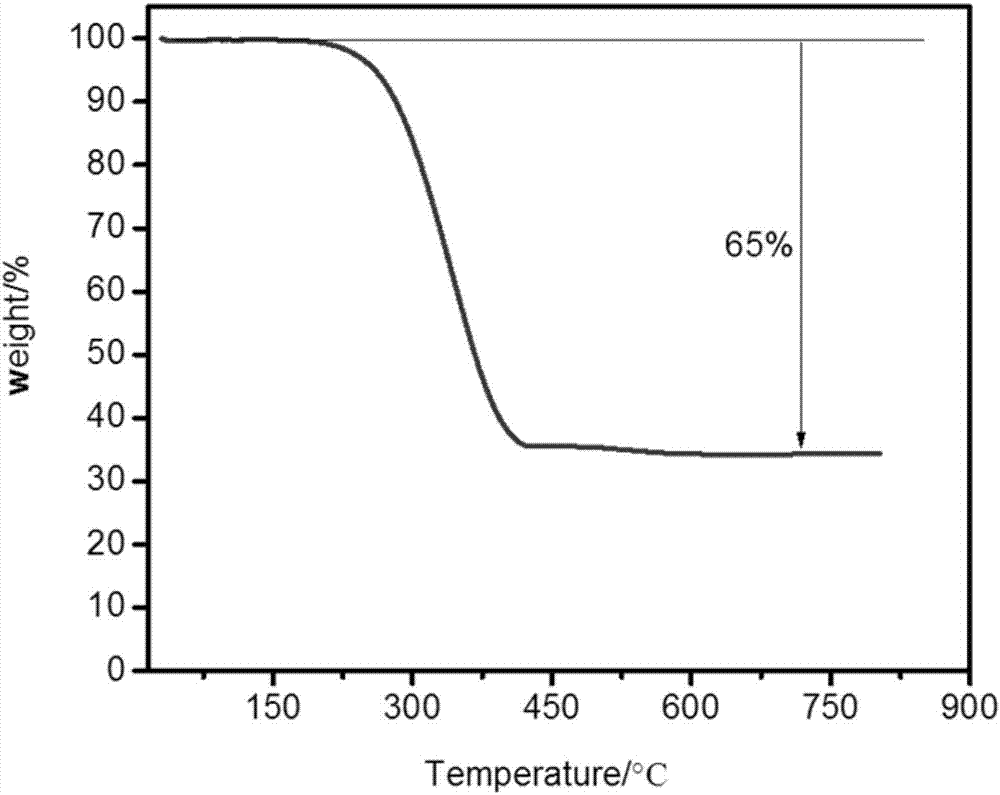

[0048] 4) Washing and drying: the AC prepared above was sequentially washed with 1mol L -1 The HCl solution was washed three times, washed twice with water until pH = 7, and finally dried in an oven at 120°C for 24 hours to obtain activated carbon. The resulting AC has a specific surface ar...

Embodiment 2

[0052] The activation temperature in Example 1 was changed to 1000° C., and other conditions remained unchanged. The resulting AC specific surface area is 1702 cm 2 / g, the pore volume is 0.92cm 3 / g. See [Table 2] for specific parameters.

[0053] The structural parameters of the activated carbon obtained in table 2 embodiment 2

[0054]

Embodiment 3

[0056] The activation temperature in Example 1 was changed to 800° C., and other conditions remained unchanged. The obtained AC specific surface area is 1247cm 2 / g, the pore volume is 0.66cm 3 / g. See [Table 3] for specific parameters.

[0057] The structural parameters of the activated carbon obtained in table 3 embodiment 3

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com