3D printing positive electrode material, preparation method and application thereof

A 3D printing and cathode material technology, applied in the field of 3D printing cathode material preparation, can solve problems such as difficulty in improving the specific capacity and rate performance of electrode materials, difficulty in controlling the proportion of effective active substances in batteries, affecting ion diffusion rate, etc., to achieve high-efficiency electronic Transfer efficiency, good conductive network, the effect of improving the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

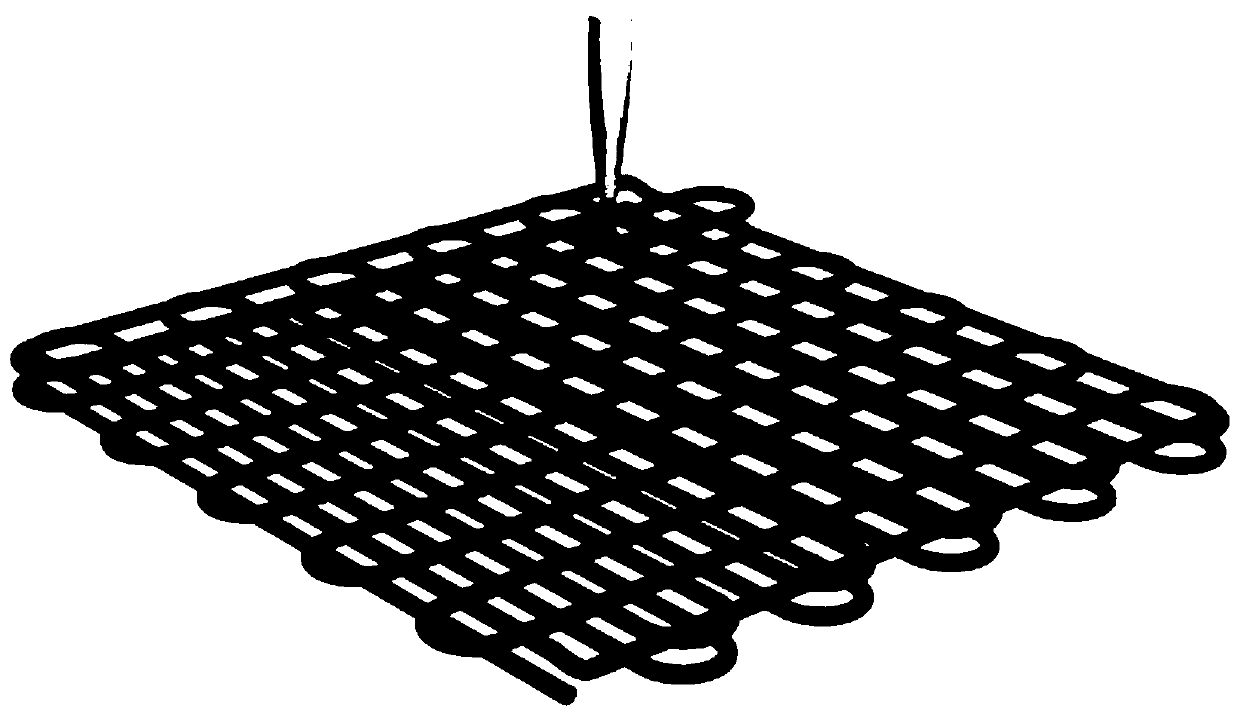

[0031] As an aspect of the technical solution of the present invention, it relates to a method for preparing a 3D printing cathode material for lithium-sulfur batteries, which mainly includes: (1) lithium-sulfur battery cathode composite materials (active material, conductive agent, (2) 3D printing to prepare a positive electrode material film; (3) dry the electrode material and perform thermogravimetric analysis and SEM characterization; (4) dry the heat treatment of the electrode material; (5) reducing and drying the heat-melted material to form a film.

[0032] In some embodiments, the preparation method mainly includes the following steps:

[0033] Mix active material, conductive agent, binder and solvent uniformly to prepare electrode slurry;

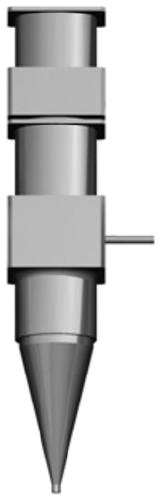

[0034] Using 3D printing technology, placing the electrode slurry on the inner layer of the coaxial printing needle, placing the graphene oxide solution on the outer layer of the coaxial printing needle, and performing coaxial pri...

Embodiment 1

[0078] The specific steps of the 3D printing positive electrode material preparation method for lithium-sulfur batteries in this embodiment are:

[0079] (1) Weigh 18g of active substance sulfur, 300g of single-wall carbon nanotube conductive paste (including binder PTFE, solvent water) in a ball mill jar, wherein, single-wall carbon nanotube is 9g, PTFE is 3g, put 100g of agate zirconium strains with a diameter of 1mm are ground in a ball mill to evenly form electrode conductive paste;

[0080] (2) Put the above-mentioned prepared composite material into a 10mL syringe 1, and fix the syringe 1 on the intelligent syringe pump 1, put the prepared graphene oxide (GO) into the 10mL syringe 2, and put the syringe 2 fixed on the intelligent syringe pump 2;

[0081] (3) Connect the above two syringes to the coaxial printing needle at the same time, wherein the syringe 2 is connected to the outer layer of the printing needle, and the syringe 1 is connected to the inner layer of the ...

Embodiment 2

[0090] The specific steps of the 3D printing positive electrode material preparation method for lithium-sulfur batteries in this embodiment are:

[0091] (1) Weigh 14g of the composite material of active substance sulfur and single-walled carbon nanotubes, 7g of Ketjen black, 2.4g of polyvinylidene fluoride, and 50mL of solvent N-methylpyrrolidone in a grinding jar, put 30g, diameter Agate zirconium strains of 2mm are ground in a ball mill to evenly form electrode conductive paste;

[0092] (2) Put the above-mentioned prepared composite material into a 10mL syringe 1, and fix the syringe 1 on the intelligent syringe pump 1, put the prepared graphene oxide (GO) into the 10mL syringe 2, and put the syringe 2 fixed on the intelligent syringe pump 2;

[0093] (3) Connect the above two syringes to the coaxial printing needle at the same time, wherein the syringe 2 is connected to the outer layer of the printing needle, and the syringe 1 is connected to the inner layer of the print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com