Lithium-sulfur battery composite cathode material, and preparation method and application thereof

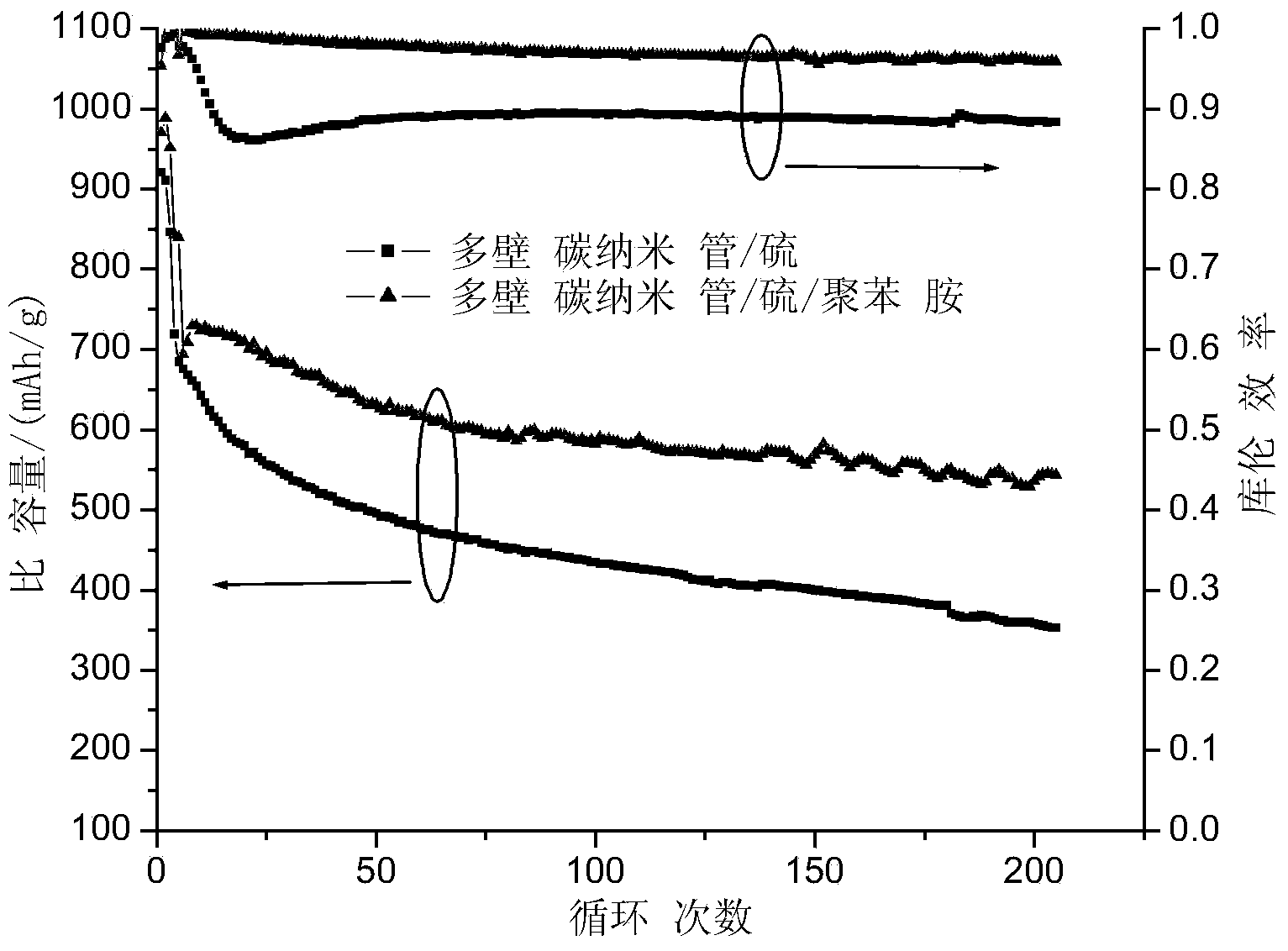

A composite positive electrode material and lithium-sulfur battery technology, applied in the field of electrochemistry, can solve the problems of low cycle stability and capacity retention, low sulfur loading of composite materials, and poor stability of finished products, so as to improve cycle stability and capacity retention efficiency, enhanced dissolution and diffusion, and increased electronic and ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of multi-walled carbon nanotube / sulfur composite material, its preparation method is as follows:

[0061] (1) Add 4g of raw material multi-walled carbon nanotubes into 400mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid (volume ratio of concentrated nitric acid and concentrated sulfuric acid: 3:1), sonicate for 2h, heat and reflux in an oil bath at 100°C for 6h, and filter , washed with deionized water until neutral, and vacuum-dried at 100°C to obtain purified multi-walled carbon nanotubes;

[0062] (2) Weigh 0.5 g of purified multi-walled carbon nanotubes and disperse them in 100 mL of deionized water for 8 h, then add 3.87 g of sodium thiosulfate pentahydrate and 5 mL of cetyltrimethylammonium bromide solution with a concentration of 5 wt%. , accompanied by vigorous stirring; use 19 mL of dilute hydrochloric acid with a concentration of 2 mol / L to titrate the reaction for 2 hours, the titration rate is controlled at 30-40 drops per m...

Embodiment 2

[0066] A kind of multi-walled carbon nanotube / sulfur composite material, its preparation method is as follows:

[0067] (1) Add 4g of raw material multi-walled carbon nanotubes into 400mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid (volume ratio of concentrated nitric acid and concentrated sulfuric acid: 3:1), sonicate for 2h, heat and reflux in an oil bath at 100°C for 6h, and filter , washed with deionized water until neutral, and vacuum-dried at 100°C to obtain purified multi-walled carbon nanotubes;

[0068] (2) Weigh 0.5g of purified multi-walled carbon nanotubes and disperse them in 100mL of deionized water for 8h, then add 5.81g of sodium thiosulfate pentahydrate and 6mL of 5wt% cetyltrimethylammonium bromide solution , accompanied by vigorous stirring; use 28 mL of dilute hydrochloric acid with a concentration of 2 mol / L to titrate the reaction for 2 hours, the titration rate is controlled at 30-40 drops per minute, filter after the reactio...

Embodiment 3

[0072] A kind of multi-walled carbon nanotube / sulfur composite material, its preparation method is as follows:

[0073] (1) Add 4g of raw material multi-walled carbon nanotubes into 400mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid (volume ratio of concentrated nitric acid and concentrated sulfuric acid: 3:1), sonicate for 2h, heat and reflux in an oil bath at 100°C for 6h, and filter , washed with deionized water until neutral, and vacuum-dried at 100°C to obtain purified multi-walled carbon nanotubes;

[0074] (2) Weigh 0.5 g of purified multi-walled carbon nanotubes and disperse them in 100 mL of deionized water for 8 h, then add 9.03 g of sodium thiosulfate pentahydrate and 7 mL of cetyltrimethylammonium bromide solution with a concentration of 5 wt%. , accompanied by vigorous stirring; use 44 mL of dilute hydrochloric acid with a concentration of 2 mol / L to titrate the reaction for 2 hours, the titration rate is controlled at 30-40 drops per m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com