Nitrogen doped porous carbon/sulfur composite positive material as well as preparation method and application thereof

A nitrogen-doped porous carbon and composite cathode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low cycle stability and rate performance, poor product stability, and high production costs, and achieve large The effect of specific surface area and pore volume, reducing process cost and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

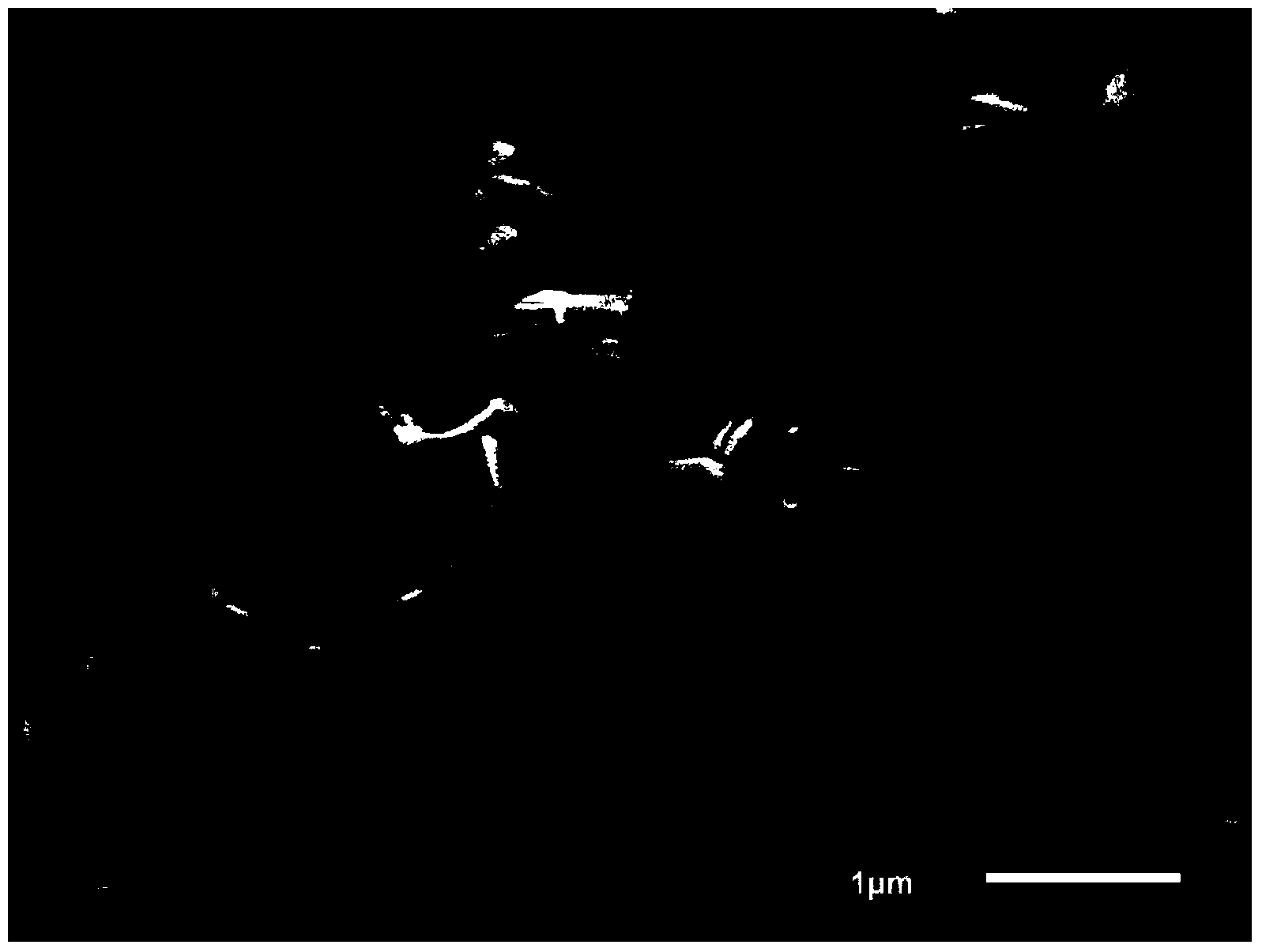

[0060] A nitrogen-doped porous carbon material, the preparation method of which is as follows:

[0061] (1) Put 10.0g tetrasodium ethylenediaminetetraacetic acid into a porcelain ark with a volume of 14cm*4cm*2cm, put the porcelain ark into a tube furnace, seal it, pump air, and the vacuum degree is -0.085MPa. Inject high-purity argon inert gas, the flow rate is 200cc / min, heat up to 600°C, the heating rate is 5°C / min, keep the temperature for 2h, and naturally cool to room temperature to obtain solid powder;

[0062] (2) Wash the solid powder obtained in step (1) successively with 0.1mol / L dilute hydrochloric acid and deionized water, and filter until the filtrate is neutral;

[0063] (3) The solid powder obtained by filtering in step (2) was heated and dried at 100° C. for 24 hours, ground, and weighed to obtain 0.428 g of the nitrogen-doped porous carbon material, which was named NDPC600.

Embodiment 2

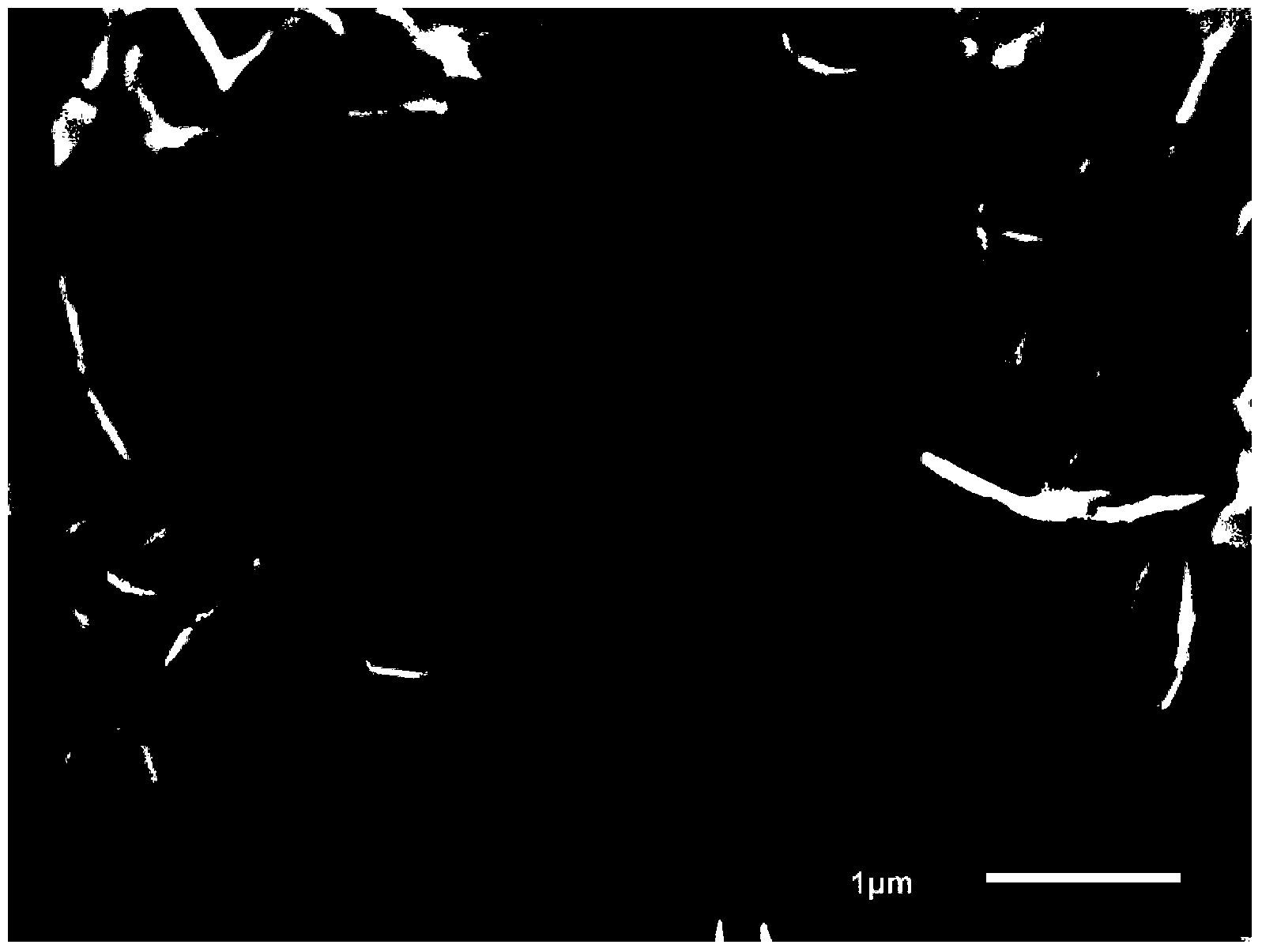

[0065] A nitrogen-doped porous carbon material, the preparation method of which is as follows:

[0066] (1) Put 20.0g of tetrasodium edetate into a porcelain ark with a volume of 14cm*4cm*2cm, put the porcelain ark into a tube furnace, seal it, pump air, the vacuum degree is -0.085MPa, pass Inject high-purity argon inert gas with a flow rate of 200cc / min, heat up to 700°C at a rate of 5°C / min, keep the temperature constant for 2h, and cool naturally to room temperature to obtain solid powder;

[0067] (2) Wash the solid powder obtained in step (1) successively with 0.1mol / L dilute hydrochloric acid and deionized water, and filter until the filtrate is neutral;

[0068] (3) The solid powder obtained by filtering in step (2) was heated and dried at 100° C. for 24 hours, ground, and weighed to obtain 0.736 g of the nitrogen-doped porous carbon material, which was named NDPC700.

Embodiment 3

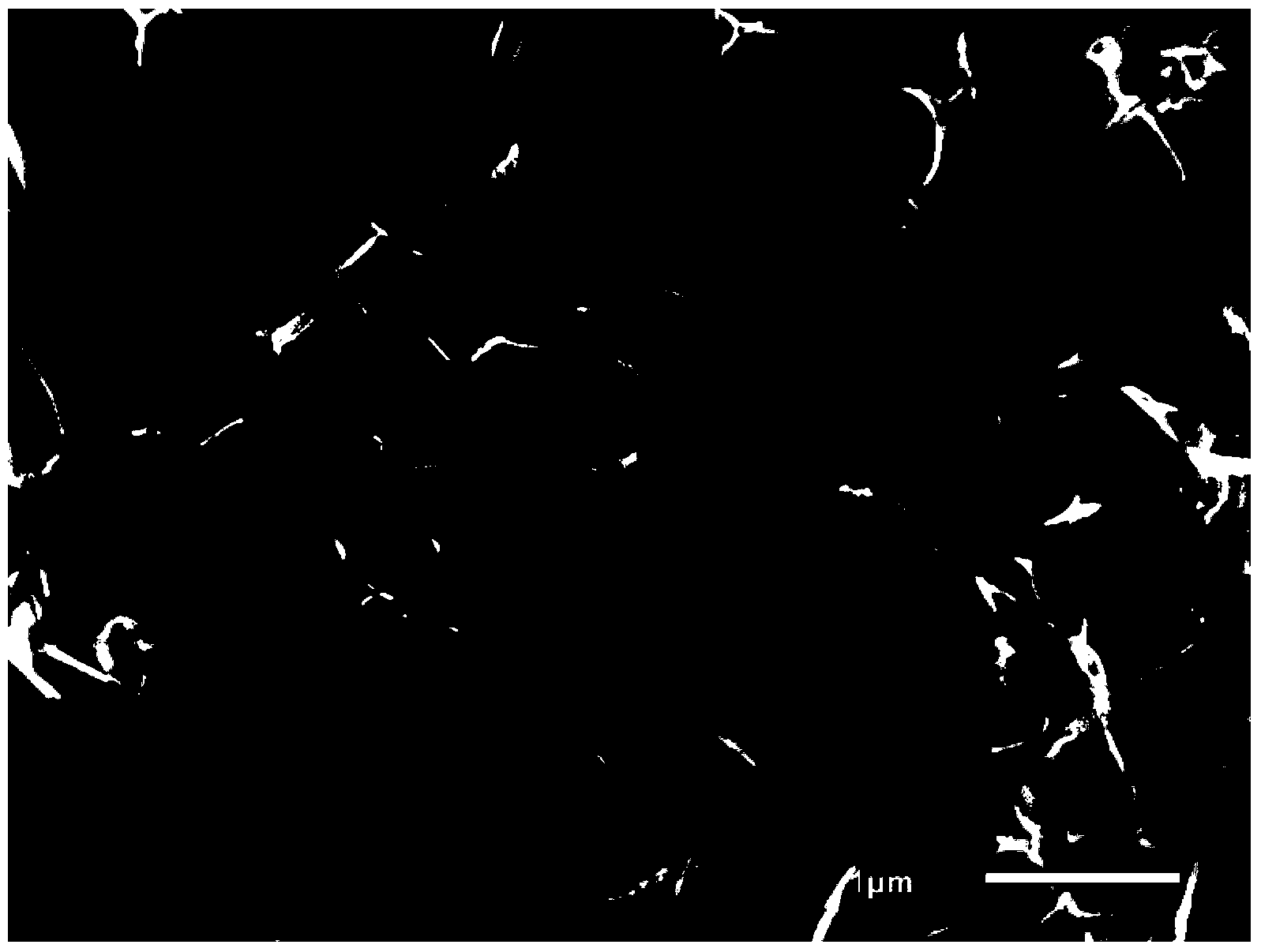

[0070] (1) Put 16.0g of tetrasodium edetate into a porcelain ark with a volume of 14cm*4cm*2cm, put the porcelain ark into a tube furnace, seal, pump air, and the vacuum degree is -0.085MPa, pass Inject high-purity argon inert gas with a flow rate of 200cc / min, heat up to 800°C at a heating rate of 5°C / min, keep the temperature constant for 2h, and cool naturally to room temperature to obtain a solid powder;

[0071] (2) Wash the solid powder obtained in step (1) successively with 0.1mol / L dilute hydrochloric acid and deionized water, and filter until the filtrate is neutral;

[0072] (3) The solid powder obtained by filtering in step (2) was heated and dried at 100° C. for 24 hours, ground, and weighed to obtain 0.4196 g of the nitrogen-doped porous carbon material, which was named NDPC800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com