Polypyrrole, mesoporous carbon and sulfur composite electrode material and secondary cell

A composite electrode and composite material technology, applied in non-aqueous electrolyte batteries, battery electrodes, circuits, etc., can solve the problems of high conductivity, specific surface area, large mechanical strength, poor cycle performance of polypyrrole, and low energy density, etc. The effect of draining, improving cycle stability, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

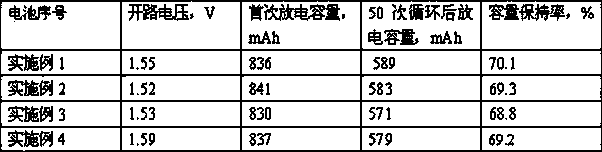

Examples

Embodiment 1

[0052] (1) The metal oxide V 2 o 5 Mix it with elemental sulfur (passed through a 400-mesh sieve) at a mass ratio of 10:1, ball mill at a speed of 200r / min for 5h under nitrogen protection, and then dry in a desiccator to form a composite material.

[0053] (2) Preparation of secondary aluminum battery: The above-mentioned composite material and binder PVDF (ratio: 9:1) are made into active material slurry, coated on a 0.6mm thick carbon-coated aluminum current collector, dried and rolled to About 0.33mm, cut into 40mm wide × 15mm long pole piece as the positive pole piece, and 0.16mm thick glass fiber non-woven diaphragm and negative pole are wound into a battery core and put into a nickel-plated steel case, and then injected with aluminum chloride-triethyl Amine hydrochloride ionic liquid, sealed to make AA-type cylindrical secondary aluminum battery.

Embodiment 2

[0055] (1) Prepare a mixed solution of 10ml tetrabutyl titanate and 5ml ethanol, add elemental sulfur to 100ml water first, then add the prepared mixed solution, place the mixed solution in a constant temperature water bath at about 60°C, stir while ultrasonically oscillating, and react 2 After ~10h, centrifuge to separate the precipitate, wash it with deionized water and ethanol, and dry it in vacuum at about 40°C to obtain a composite material;

[0056] (2) Preparation of secondary aluminum battery: The above composite material and binder PVDF (ratio: 9:1) are made into active material slurry, coated on a 0.6mm thick nickel foam substrate, dried and rolled to about 0.33mm, Cut into a 40mm wide × 15mm long pole piece as the positive pole piece, wind it into a battery core with a 0.16mm thick glass fiber non-woven separator and a negative pole, put it into a nickel-plated steel case, and then inject aluminum bromide-triethylamine hydrochloride Ionic liquid, sealed to make AA-t...

Embodiment 3

[0058] Measure 10ml of butyl titanate at room temperature, slowly drop it into 35ml of absolute ethanol, stir vigorously with a magnetic stirrer for 10min, and mix well to form a yellow clear solution A. Add 4ml of glacial acetic acid and 10ml of distilled water to another 35ml of absolute ethanol, stir vigorously to obtain solution B, drop in 1~2 drops of hydrochloric acid, and adjust the pH value so that the pH value is ≤3. In a water bath at room temperature, slowly drop the solution A that has been transferred into the constant pressure funnel into the solution B under vigorous stirring at a rate of about 3ml / min. After the dropwise addition, a light yellow sol was obtained. Add the sulfur element into the sol and stir evenly, then vacuum-dry at 80°C for 24 hours to form a gel, and then calcinate the gel at 500°C for 2-5 hours to form a composite material.

[0059] The preparation of the secondary aluminum battery is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com