Method for millimeter-sized micro nanostructure nano carving and processing through adopting antifrictional metal (AFM) needle

A technology of micro-nano structure and micro-structure, applied in the directions of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve problems such as the limitation of scanning range of scanning ceramic tubes, and achieve the integration of processing and detection, the method is simple, and the equipment And the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

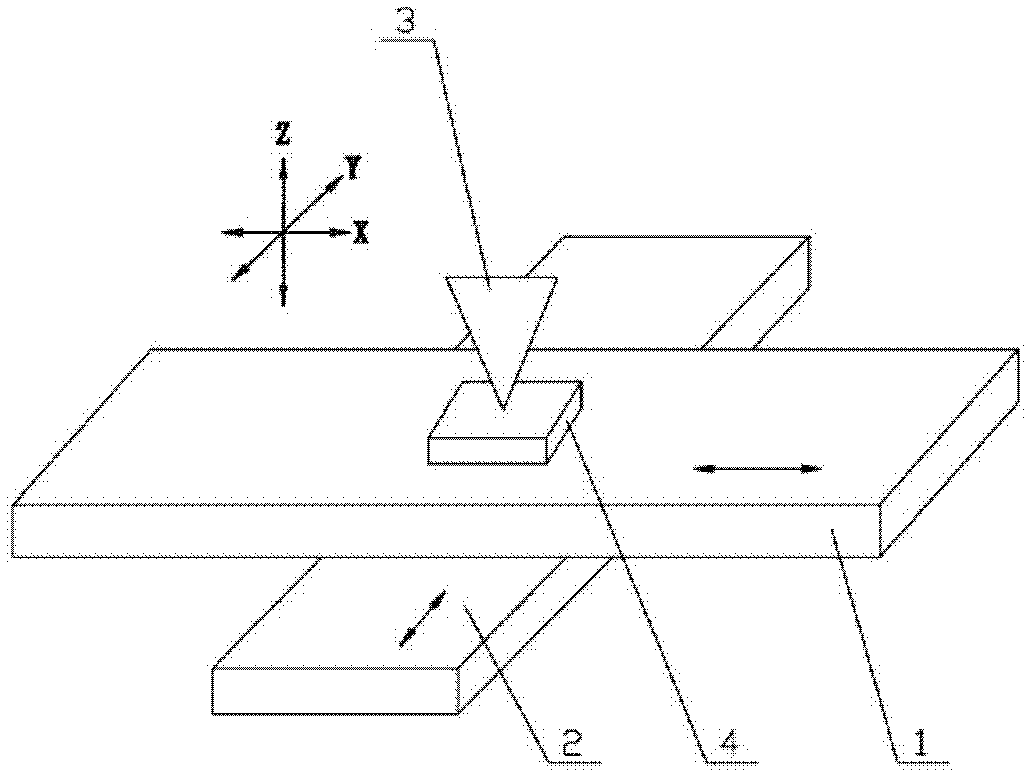

[0023] Specific implementation mode one: as Figure 1a ~ Figure 1c and Figure 3b , a method for processing millimeter-sized micro-nano structures using AFM probe nanometer scribing, the method is implemented by the following steps:

[0024] Step 1: first place the sample 4 to be processed on the X-Y two-dimensional precision workbench, and determine the starting point of the structure to be processed of the sample 4 to be processed within the range of length × width = 100mm × 100mm through the X-Y two-dimensional precision workbench; then pass The approach process of the AFM system makes the AFM probe 3 contact the surface of the sample 4 to be processed with a vertical load less than 1 μN;

[0025] Step 2: Process the nanowire vibrating structure; first set the scanning range of the AFM to 0 μm, and then set the parameter values of the processing length, processing width, processing distance, processing direction, vertical load and processing speed, and the above-mentione...

specific Embodiment approach 2

[0027] Specific implementation mode two: as Figure 1a ~ Figure 1c and Figure 3c , a method for processing millimeter-sized micro-nano structures using AFM probe nanometer scribing, the method is implemented by the following steps:

[0028] Step 1: first place the sample 4 to be processed on the X-Y two-dimensional precision workbench, and determine the starting point of the structure to be processed of the sample 4 to be processed within the range of length × width = 100mm × 100mm through the X-Y two-dimensional precision workbench; then pass The approach process of the AFM system makes the AFM probe 3 contact the surface of the sample 4 to be processed with a vertical load less than 1 μN;

[0029] Step 2: Processing an array microstructure composed of multiple identical single microstructures; the shape of a single microstructure is circular, square or equilateral triangle, the diameter of a single circular microstructure is 5 μm-50 μm, and a single The side length of the...

Embodiment 1

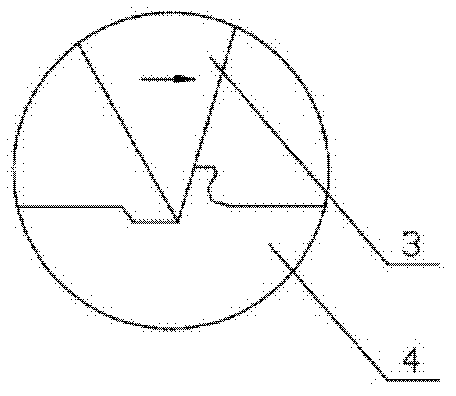

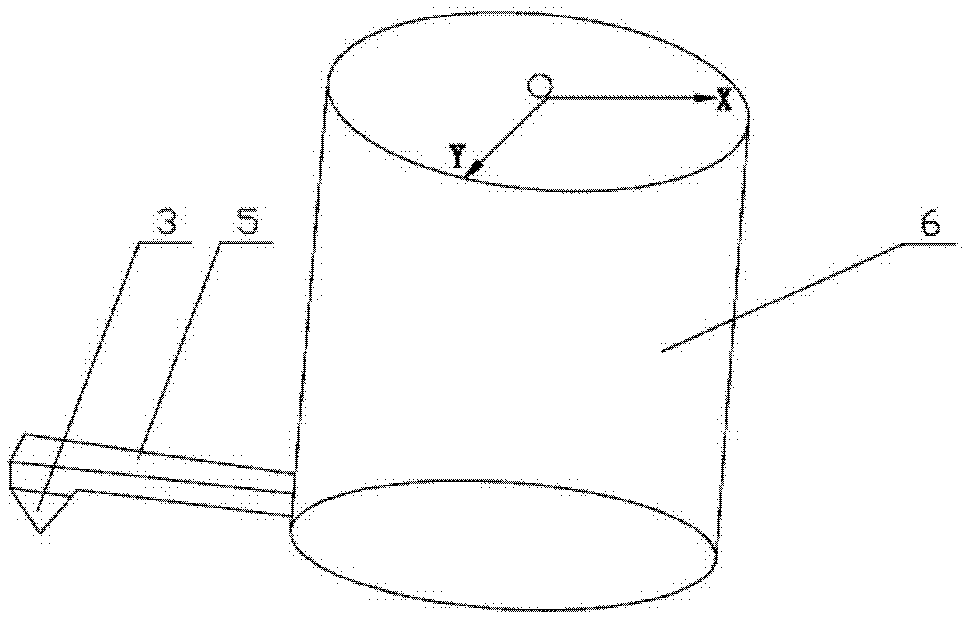

[0031]Embodiment 1: Taking the realization process of machining an equilateral triangle microstructure on the surface of a sample to be processed as an example to describe the realization of the coordinate acquisition and movement of a single microstructure: using the Ambios Qscope 250 of Quesant Instrument Corporation of the United States TM The V4.05 version software of the AFM system, the software provides the Slew_xy(x, y) function to control the precise movement of the AFM scanning ceramic tube 6 to drive the AFM probe 3, and this function controls the movement of the AFM probe to the (x, y) coordinates place. Therefore, as long as the figure 2 The start and end coordinates of each line shown in the figure can realize the movement of the AFM probe 3 by calling the Slew_xy function to complete the processing, such as Figure 1a ~ Figure 1c .

[0032] The process of obtaining coordinates: such as figure 2 As shown, when the equilateral triangle microstructure is proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com